Since 1955, Ductile iron pipe has been the choice for modern water and wastewater systems. It has excelled in strength, durability, and reliability for transporting raw and potable water, sewage, slurries, and process chemicals.

Designed and manufactured to the industry's most stringent standards, Ductile iron pipe resists damage during shipping and handling, and once installed, it withstands the most demanding operating conditions, including water hammer, frozen ground, deep trenches, high water table areas, heavy traffic areas, river crossings, pipe on supports, rocky ditches, and shifting, expansive, and unstable soils.

-

Tyton® Joint Pipe

Tyton® Joint pipe is manufactured by McWane Ductile in 3-inch to 36-inch diameters in special “Thickness Class” and standard “Pressure Class” selections.

-

TR Flex® Restrained Joint Pipe

Simply put, the most-widely accepted and installed integrally-cast restraint joint system in the ductile iron pipe industry.

-

Mechanical Joint Pipe

The "original" modern pipe joint, circa 1925; the Mechanical Joint remains in use primarily as a means for connecting fittings, valves, and similar appurtenances to a pipeline.

-

Mechanical Joint Lock Joint Pipe

The Mechanical Joint (MJ) Lock Joint can be used with mechanical joint pipes, fittings, and valves as a means of creating a restrained joint when a mechanical joint connection has been specified. One MJ gland is used to secure the gasket and create a watertight seal, while the second MJ gland is used for joint restraint.

-

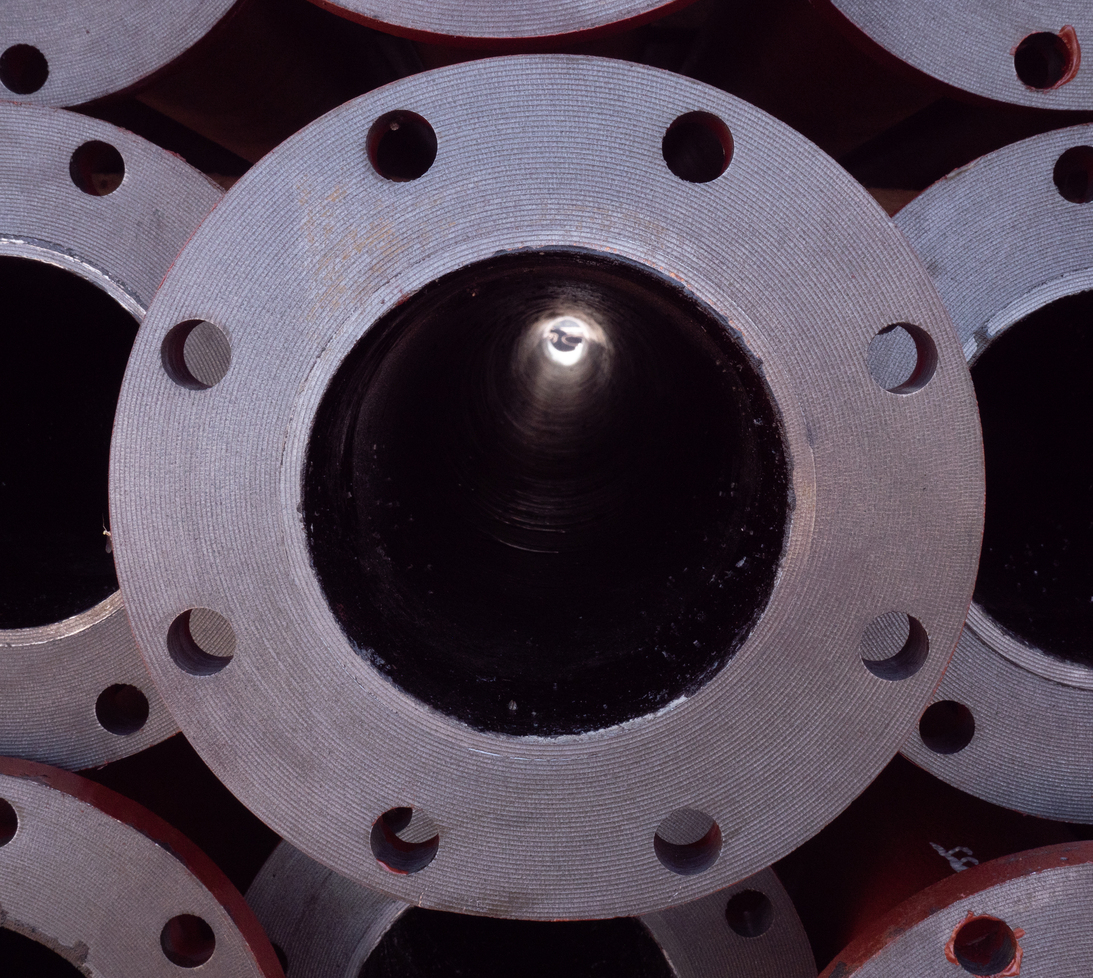

Fabricated Flange and Wall Pipe

Fabricated pipe is made to custom lengths to meet specific project needs.

-

Ball and Socket Joint Pipe

McWane Ductile’s Ball and Socket River Crossing Ductile Iron Pipe is made with a specially machined Ductile iron ball and bell that offers 15 degrees of deflection per joint.

-

Long-Span Pipe

As the name suggests, Long-Span Pipe can extend over distances with fewer supports than conventional Ductile iron pipe.

-

Permaloy™ Pipe

Permaloy™ Abrasion Resistant Pipe is alloyed centrifugally cast Ductile iron pipe, offering superior abrasion resistance for hydraulic or pneumatic conveyance of fly and bottom ash, mine tailings, sewage, and other abrasive materials.

-

Seismic Flex Coupling™

Whether it's ground displacement, liquefaction, strain along a fault line or structure, McWane Ductile’s Seismic Flex Coupling™ provides a reliable, economical solution.