Misleading information has recently circulated regarding the availability of TR Flex® restrained joint pipe and fittings, creating a flurry of questions and uncertainty for engineers and utilities about its service performance and integrity. How can an engineer design a project without knowing the facts? After reviewing the information in this #IronStrong Blog, one can better understand future expectations.

HOW LONG HAS TR FLEX® PIPE BEEN IN SERVICE?

Before going further, let’s first provide a brief history. TR Flex pipes have been installed for more than four decades and have proven reliable. They are suitable for use in high-pressure applications, seismic-prone areas, deep bury, HDD (horizontal directional drilling), and penstocks, among others. McWane Ductile has yet to experience any TR Flex joint failures during our 15+ years of manufacturing more than 40,000 pieces annually.

HOW IS TR FLEX® PIPE MANUFACTURED BY MCWANE DUCTILE TESTED?

McWane Ductile manufactures various Ductile iron pipe joints, including the TR Flex pipe, which conforms to ANSI/ AWWA C150 and C151 standards. All pipes, regardless of class, undergo rigorous hydrostatic testing to a minimum of 500 psi. This testing ensures the pipe can withstand significant pressure without leaks or failures. Additionally, McWane Ductile conducts random testing of assembled pipe joints at a minimum of two times the rated pressure, exceeding AWWA standards. This additional testing provides an extra layer of assurance about the product's quality and reliability. For instance:

- Testing at 300 psi equates to a 150 psi rating

- Testing at 500 psi equates to a 250 psi rating

- Testing at 700 psi equates to a 350 psi rating

WHAT IS THE BASIS FOR THE CONFUSION?

Who enjoys a good "word salad?" Conflicting information regarding the pressure ratings for TR Flex pipe has been posted on the U.S. Pipe website and published in formal letters over the years. For example:

- In 2013, the pressure ratings for all sizes of TR Flex pipe were published in product literature found on the website.

- Beginning in 2016, it was stated that 30” and 36" TR Flex pipe and fittings had a 100 psi reduction in joint rating for a given parent pipe.

- Subsequently, in 2019, the word "fittings" was dropped without explanation.

- Lastly, in 2021, a letter was published that stated that 30” and 36” Pressure Class 150 pipe was only rated to 50 psi working pressure for TR Flex restrained joint pipe.

The published information continuously evolved, leading one to wonder why a flagship product that a company developed and proudly heralded for decades is now being "weakened in words only" by that same company. During the same period that this confusing information was presented, the HDSS joint was actively promoted as a substitute product. Therefore, it's important to question whether the gradual changes in performance information were an attempt to “buy time” during the product development and testing process and reduce the surprise felt by engineers as they realized that the products they had been so sure about were no longer the same.

AS AN ENGINEER, WHY IS THIS APPROACH HARMFUL TO ME?

Having multiple approved products for piping ensures the strength and stability of our nation's infrastructure. Eliminating competition and available product options could lead to increased pricing and the potential for supply chain disruptions. This is especially true on large-scale projects, which are often broken down into various phases. Completion dates are more easily met due to multiple contractors and suppliers working on separate phases simultaneously.

SO, WHAT IS REALLY NEEDED?

Design engineers usually consider operating or "working" pressure when designing for maximum efficiency. Most waterlines operate well below the previously mentioned thresholds, often at less than 100 psi working pressure. For example, using the internal pressure and the ANSI/AWWA C151 Thickness Design of Ductile-Iron Pipe, take the following parameters: 36” pipeline operating at 100 psi (typically Hydrostatic tested at 150 psi), depth of bury at 8', and a Trench Type of II. See the diagram below, which shows the calculation results for wall thickness.

The required wall thickness for Ductile iron pipe is a mere .068 thickness. The standard wall thickness for a 36" TR Flex Class 150 pipe is .38 nominal, five times the required calculated thickness for the given parameters. This additional thickness provides a safety margin, ensuring the pipe's structural integrity under various operating conditions.

Additional considerations are found in paragraph 4.1.2 of the ANSI/AWWA C151 Standard "Design for Trench Load" for the depth of bury and a trench Type II; this project's suggested class of pipe will be C200 pipe. Would anyone specify a Class 350 pipe for this project? Quite simply, NO. The 36" TR Flex Class 200 pipe is more than sufficient. Calculations are provided within seconds using the McWane Pocket Engineer at PE.McWane.com.

CLEAR PRODUCT INFORMATION IS CRITICAL

In conclusion, as key decision-makers in water projects, engineers and utilities deserve and should demand accurate information. This is crucial for making sound decisions and ensuring the success of their projects. The facts presented show that TR Flex pipe joints have a proven track record of success. We want to be clear: McWane Ductile has not de-rated any products. McWane Ductile is committed to manufacturing the TR Flex joint and will continue to do so. We manufacture our products in our three domestic facilities, employing local union workers who prioritize safety and environmental responsibilities. We encourage water professionals to contact your local McWane Ductile representatives or Technical Engineers for further information or clarification.

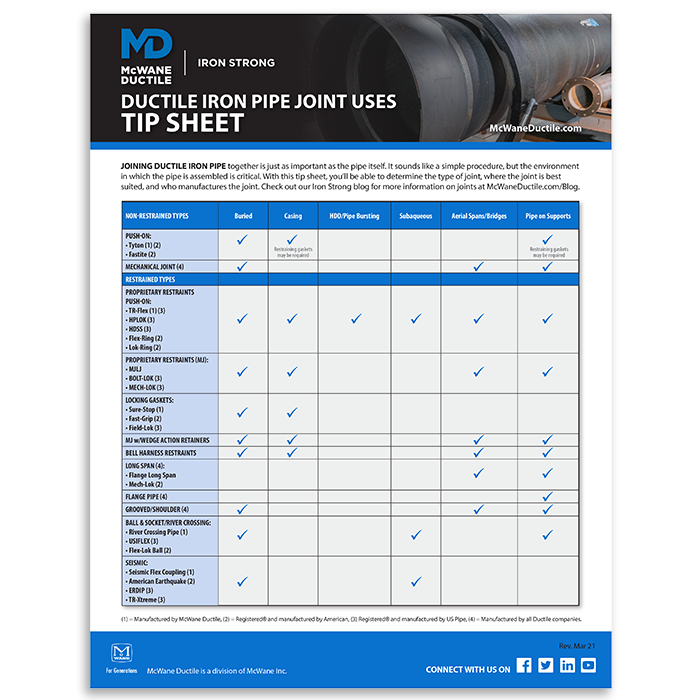

Is it the right Ductile iron pipe joint for the job? Be sure with this free and handy tip sheet listing various DI Pipe joints and their uses from McWane Ductile!

DOWNLOAD NOW

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is equipped with the expertise to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.