Selecting the right pipe material is essential for the longevity and success of any water infrastructure project. While Ductile iron pipe (DI pipe) and High-Density Polyethylene (HDPE) each offer distinct benefits, their differences in strength, performance, and long-term costs are significant. This article serves as a refresh of our previously published article in November 2019. It outlines key comparisons to help engineers and specifiers make informed decisions based on project-specific conditions, such as soil type, pressure, and environmental factors.

Click here to refer to our previously published comparison article on DI pipe vs. HDPE.

Recyclability and Sustainability

High-density polyethylene (HDPE) is made from ethylene derived from petroleum and natural gas. To form HDPE pipe, ethylene in pellet form is melted into a molding machine and then extruded into its finished pipe form. Little to no true recycling is involved with HDPE products manufactured for the water and sewer industry, and reuse requires extensive cleaning.

In contrast, Ductile iron pipe is made from ferric scrap metal typically containing at least 90 percent recycled content—mostly old automobiles—and is fully recyclable after use. This makes DI pipe an environmentally sound choice with a strong sustainability profile.

DI Versus HDPE? The Strength is in the Numbers

The structural superiority of Ductile iron pipe is clear:

- Hydrostatic Design Basis (HDB): DI pipe: 21,000 psi. HDPE: 800 psi—a 26-fold difference when a Safety Factor of 2.0 is applied.

- Yield Strength: DI pipe: 42,000 psi. HDPE: 1,600 psi (before safety factors).

- Wall Thickness & Pressure Resistance (12-inch example):

- HDPE at 0.14": withstands only 34 psi.

- DI pipe at 0.14": withstands 900 psi.

- Minimum DI pipe wall of 0.25": withstands 1,590 psi.

- HDPE at 0.25": withstands just 60 psi.

It should be noted that HDPE design standards do not include or involve any surge allowance, even though measurable surges will occur every time transported fluids speed up or slow down within the pipes. This is simply a fact. Why bother with it? HDPE design standards "absorb" the surges into the safety, thereby reducing the true safety factor to less than 2.0

Larger HDPE pipes face additional challenges, as extrusion limitations reduce pressure ratings for diameters exceeding 20 inches. HDPE also lacks consistent material strength, whereas Ductile iron pipe utilizes a single, proven grade—60-42-10 Ductile iron.

A Crushing Omission - External Load Resistance

External loading is often overlooked in HDPE design and wall selection, yet it is a core component of Ductile iron pipe specifications. DI pipe thickness design for buried pipelines is designed with trench types, bending stress, and deflection in mind—critical for underground durability. And while there are no specified trench conditions for HDPE pipe in their standards, there are five (5) specified trench conditions for DI pipe in their standards, providing cost-effective, tailored support and protection for the pipelines based on the actual needs of the system in concert with adjacent native soil conditions. HDPE standards, however, omit trench condition guidance, which can often lead to over-excavation and unnecessary costs.

Live loads, such as AASHTO H-20 traffic (16,000 lb per wheel), are incorporated into DI pipe designs but excluded from HDPE standards. This omission is a critical flaw when designing for real-world service.

Temperature and Longevity – Does it Matter?

Ductile iron pipe is unaffected by temperatures from -40°F to 212°F. It has a service life that easily exceeds 100 years.

HDPE, however, is highly temperature-sensitive:

- Its design basis assumes a fixed temperature of 73.4°F.

- For every 10°F temperature shift, HDPE expands or contracts 10 inches per 1,000 feet.

- HDPE loses strength with colder temperatures—most water lines operate around 51°F.

- HDPE pipe walls can be deformed or weakened by pressure surges.

DI pipe is 13 times more stable concerning temperature changes (only 0.75 inches of expansion per 1,000 feet per 10°F) and easily accommodates this via its rubber gasket joints.

Additionally, the hydrostatic design basis of all thermoplastic pipe materials, including HDPE, is based upon a stress that would cause failure in just 100,000 hours of service, or 11.4 years. There are well-documented installations of gray iron, also called cast iron, that have served in some cases, for more than 300 years, particularly in the case of the Fountains at the Palace of Versailles in France. It is essential to note that Ductile iron is more resilient than gray iron and that Ductile iron is not adversely affected by time or repetitive surges.

Fitting to Be Tied

Ductile iron fittings, made per the AWWA C153 standard, do not reduce pipeline performance. In contrast, HDPE fittings—produced only by third-party vendors—reduce the pipeline’s overall pressure rating by 25%. For example, a 200 psi DR11 HDPE line drops to 150 psi if even one fitting is added.

HDPE connections to alternate piping materials typically require stiffeners and/or flanges, which are poorly suited to underground conditions due to vulnerability to shear forces. In contrast, DI pipe's rubber gasket joints offer reliable, watertight seals with fast installation and no performance trade-offs. For more information on connecting Ductile iron pipe to alternate materials, click here.

An excellent resource for exploring the numbers and differences between DI pipe and other alternative materials in more detail is the McWane Pocket Engineer, available at pe.mcwane.com. This tool is available for both desktop and mobile devices.

Ease of Installation

Ductile iron pipe installs with a simple push-on rubber gasket joint—fast and reliable. HDPE, however, requires:

- Specialized fusion equipment

- Skilled technicians

- Ideal weather or tenting for welding

- De-beading of internal fusion seams to remove flow obstructions

HDPE’s standard lengths (40–50 ft) require keeping over 100 feet of trench open during installation. DI pipe, typically in 20-foot segments, needs far less open trench—making it ideal for tight or urban spaces.

In Horizontal Directional Drill (HDD) installations, HDPE requires a 3–5-day rest period after pull-in to allow for material relaxation, which can cause costly downtime. Surface damage to HDPE (e.g., gouges exceeding 10% of the wall thickness) can disqualify the pipe—another concern not shared with robust DI pipe.

Operating Cost and Energy Use

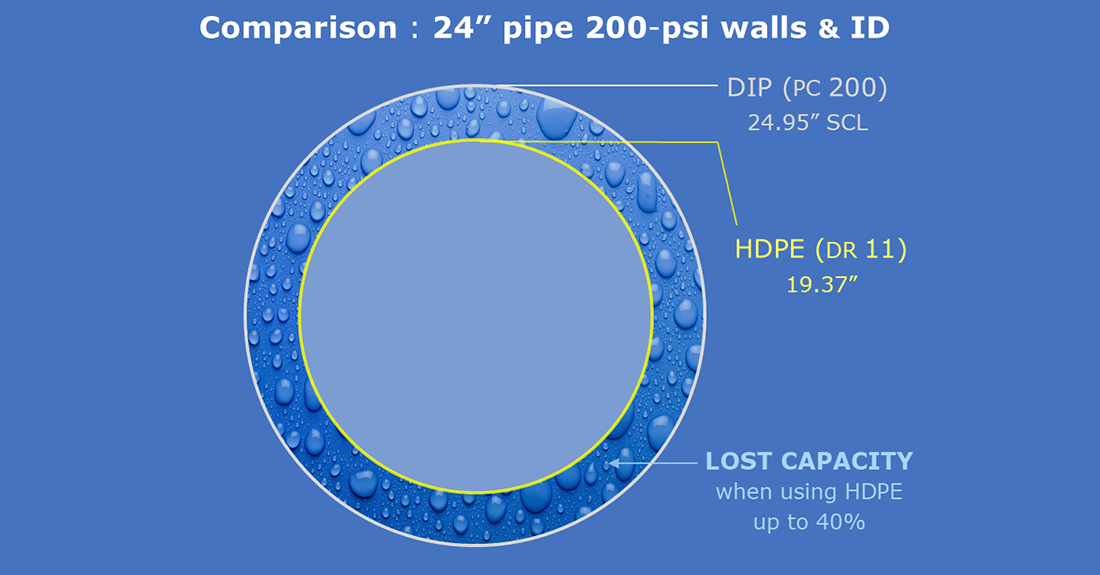

While HDPE may seem cheaper upfront, its smaller internal diameter significantly increases long-term operating costs.

Using a 12-inch pipe example:

- HDPE has an internal diameter 24–40% smaller than DI pipe.

- Pumping the same volume of water through HDPE over 25 years costs over $900,000 more per mile.

- This added friction loss offsets any material cost savings.

HDPE only makes economic sense if it is installed at $170 less per foot than DI pipe—an unrealistic difference in most cases.

Chemical and Environmental Resilience

- Oxidation: HDPE can degrade under standard water treatment conditions.

- Fire Resistance: HDPE melts at just 260°F—vulnerable even when buried. DI pipe, with a melting point of 2,100°F, remains unaffected in wildfire zones.

- Soil Contamination: HDPE is permeable to hydrocarbons and many other soil contaminants. DI pipe is not. Installing HDPE in contaminated areas requires expensive and uncertain soil remediation.

Joint Performance and Flow Obstruction

Criticism of minor gaps in DI pipe joints is unfounded. These joints, if deflected, may collect minimal silt—but not enough to affect performance.

HDPE joints, however, have significant internal and external lips from butt fusion. These can be ½ to 1 inch high and create real flow obstructions—especially problematic in sanitary sewer systems where solids may catch, leading to backups.

Summary: Why Ductile Iron Pipe is the Smart Choice

Choosing pipe material is about more than initial cost. As we’ve seen, Ductile iron pipe consistently outperforms HDPE in:

- Structural Strength

- Hydraulic Efficiency

- Temperature Stability

- Installation Ease

- Longevity and Lifecycle Cost

- Environmental Resilience

- Fitting and Joint Reliability

- Resistance to Fire and Contaminants

DI pipe handles high-pressure, high-load conditions with ease and lasts for over a century. HDPE, while flexible and lightweight, presents long-term concerns in durability, performance, and cost.

Looking Ahead

At McWane Ductile, we support our partners in making the best long-term choices for water and wastewater systems. While HDPE may be appropriate in specific scenarios, Ductile iron pipe is rarely an unsuitable choice—offering proven value and reliability across a wide range of installations. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

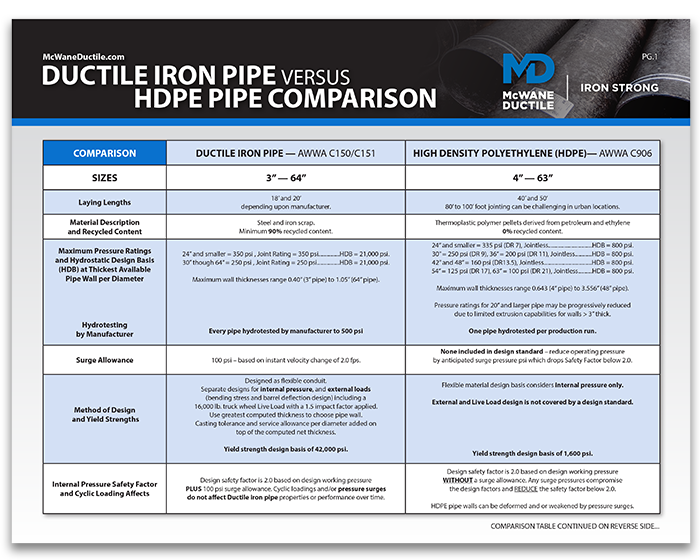

Ductile Iron Vs. HDPE Pipe Comparison Sheet

Ductile iron and HDPE (high-density polyethylene) pipe are vastly different. To further explore the differences, download our handy tip sheet or contact your local McWane Ductile representative for project-specific support.