Cement-mortar lining for iron pipe has been used for nearly 100 years. The first installation of gray iron pipe with a cement lining was recorded in Savannah, GA in 1922. Today's modern Ductile iron pipe still utilizes cement lining for a safe and reliable means of providing clean drinking water to millions of people every day.

On occasion, however, the cement lining may have incurred some damage in the field. The lining, although very durable, does not have the same resistance to bending stress or impact as the pipe itself. Certainly, the pipe or fitting should be checked for further structural damage, but once determined the affected area is only the cement lining, repairs can be made under the applicable provisions within the ANSI/AWWA C104/A21.4 standard CEMENT-MORTAR LINING FOR DUCTILE IRON PIPE AND FITTINGS.

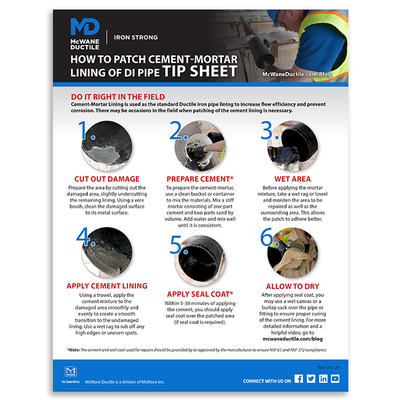

The Procedure for Repairing Cement Mortar Linings:

The process for making these repairs is outlined in the AWWA C104 standard as well as the AWWA M41 Manual of Practice for DUCTILE IRON PIPE AND FITTINGS. Prior to beginning, you should verify with the pipe manufacturer that the materials to be used, including the cement and seal coat, are suitable for use. That is, they meet the necessary requirement of the standard and are NSF 61 and NSF 372 approved.

The steps to repair are as follows:

- Cut out the damaged area completely to the metal surface, edges should be perpendicular or slightly undercut.

- Clean the damaged area and surrounding area to be repaired.

- Mix a stiff mortar consisting of one part of cement to two parts of sand by volume.

- Wet the area to be repaired as well as the area surrounding the repair.

- With a trowel, apply the cement lining to the damaged area and smooth evenly with the adjoining, undamaged lining.

- A taper of the lining thickness at the ends of the pipe or fitting is allowed under the AWWA C104 Standard. The length of the taper should be a short as possible and should not exceed 2 inches for a standard lining or 4 inches for a double thickness lining.

- If required, apply seal coat to the repaired area within 5-30 minutes following the application of the cement. A section of wet canvas or burlap can be tied to the pipe or fitting end to allow moisture retention and assist with curing of the cement lining

- NOTE: The standard lining thickness for pipe and fittings is as follows:

- 3 – 12-inch pipe - 1/16 inch

- 14 – 24-inch pipe – 3/32 inch

- 30 – 64-inch – 1/8 inch

- Double thickness linings at twice the thicknesses noted can be provided if specified by the purchaser

Pro Tip: Repairs can only be made in areas easily accessible by reach such as near the pipe or fitting ends. For pipe that has been damaged in the center, consider setting these aside for use as spools or field cut pipe.

Helpful Tips to Avoid Damage In The Field:

Finally, a few reminders to help minimize the occurrence of the damaged pipe while on the job site:

- Always handle the pipe with the proper equipment.

- Be careful not to drop or impact the pipe while unloading.

- The pipe should be properly stored on timbers – never just stacked on themselves.

- Last, it is not recommended to insert forks inside the pipe barrel for transportation as this can damage a lining beyond the ability to repair.

For additional information on repairing cement linings please contact your local McWane Ductile Sales Representative.

If the cement-mortar lining of your Ductile iron pipe gets damaged, don’t fret. It’s repairable! Know how to fix it correctly with this free Cement-Morter Lining Repair Tip Sheet.

Need Assistance With Your Waterworks Project?

McWane Ductile offers multiple services to our customers extending far beyond manufacturing DI pipe. From estimating to design, from production to installation, we take great pride in providing education and assistance to water professionals throughout the water industry.