Over the years, I have spoken with numerous engineers, utilities, and municipalities, and there seems to be a disconnect when it comes to the overall understanding of when and where cement-mortar-lined pipe can be used in wastewater applications. Due to these grey areas, engineers and owners often specify specialty linings for an entire project when the line could have been specified as either cement-mortar lined Ductile iron pipe only or a mixture of specialty lined and cement-lined pipe.

No engineer, owner, or manufacturer wants to have a sewer line fail before its useful life because the specifications did not mandate a product that could stand up to the rigors of a sewer system. However, at the same time, no one wants to burn money if they do not have to.

Therefore, this blog will address the following three topics:

- To help the reader understand the purpose of cement lining inside Ductile iron pipe.

- Address some of the misunderstandings when it comes to using cement lining for sewer applications.

- Show that there are significant financial benefits to understanding when and where to use cement-lined pipe versus specialty lined pipe.

What Is The Purpose of The Cement Lining?

Ductile iron pipe manufacturers began lining pipe with cement as early as the 1920s. In a water application, the cement lining is applied to prevent electrochemical corrosion, also known as tuberculation, from occurring on the surface of the pipe. The cement lining also increases the pH at the surface to help mitigate tuberculation. Tuberculation happens when minerals found in conveyed water attach to the bare wall of the pipe.

Over time, this tuberculation can result in restricted flow because it decreases the inside diameter, thus the cross-sectional areas of the pipe. The cement lining forms a physical barrier between the pipe wall and the minerals found in the water. This barrier does not allow the minerals to adhere to the pipe wall.

To understand more about tuberculation, see another helpful Iron Strong blog, What is Tuberculation and Why Did it Happen in Iron Pipe? by my colleague, Terry Lynch.

Understanding Corrosion and Cement-Lined DI Pipe

One thing I want to make sure everyone understands is that the cement lining IS NOT intended to give the pipe any corrosion protection against bacterial or microbiologically induced corrosion, often referred to as Hydrogen Sulfide (H2S) corrosion. If you have these issues, an increased pipe wall thickness is not an adequate means of corrosion control, either.

Most people I have spoken with over the last twenty years have one of the following two opinions when it comes to Ductile iron pipe linings for sewer applications:

1) Gravity systems do not require anything more than cement lining.

2) All sewer force mains require a specialty lining, such as Protecto 401™, to assure corrosion is not an issue.

To learn more about specialty linings, please follow this link What pipe linings are best for sewer applications? by my colleague, Dustin Henderson.

While these statements might seem logical in theory, they do not hold true in every instance. In fact, these statements can be correct and incorrect over different sections of a wastewater pipeline. That is why it is so essential first to understand what is going on in your system from station to station.

Once you know what is happening station to station, you can design a layout and specify linings appropriate for your project. Keep in mind that at some point, essentially, all sewer force mains will have sections that are gravity fed.

If the fluid flowing through your system does not have a pH below 4.5 or above 12, it is considered to be non-septic. Additionally, for a gravity system to remain non-septic, you need a minimum of at least a 1 percent slope, as well as a minimum, scour velocity, the speed that will prevent the deposition and buildup of solids in the sewer, of 2 ft/s. If these conditions are all met, then cement-lined Ductile iron pipe is all you need to specify for this application.

Another opportunity to utilize cement-lined ductile iron pipe for the entirety of a project is when you have a sewer force main where the pipe is continuously flowing full. A full pipeline will not allow Hydrogen Sulfides (H2S) to form.

You Might Be Asking, What Is H2S?

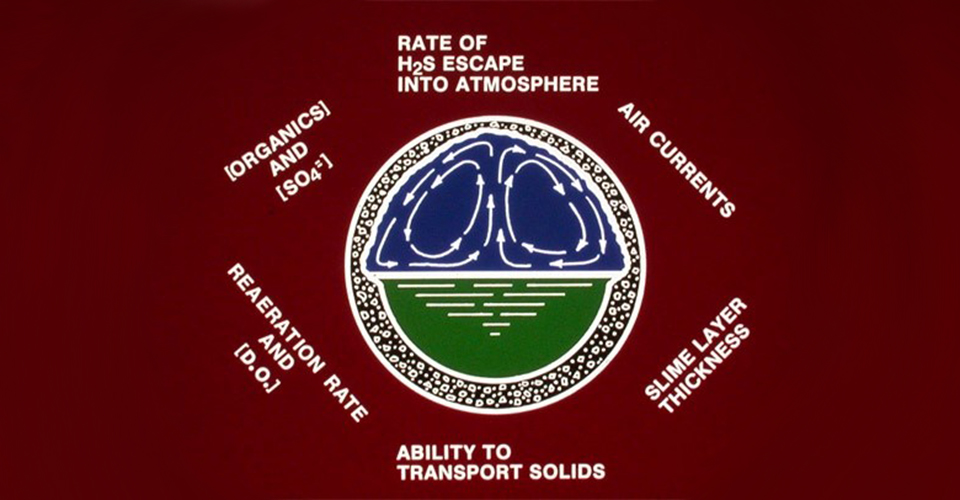

H2S corrosion can occur in gravity systems when the bacteria in the anaerobic slime layer reduces existing sulfates to Hydrogen Sulfide. The H2S is released into the pipe's crown above the flow line, where Thiobacillus bacteria further metabolize the H2S into very low pH sulfuric acid. This sulfuric acid is corrosive to the cement lining and the iron itself.

If your system is a gravity or force main and you know that you will have the presence of H2S, then some of that line will require a specialized lining. However, just having H2S does not mandate that the entire line have a special lining.

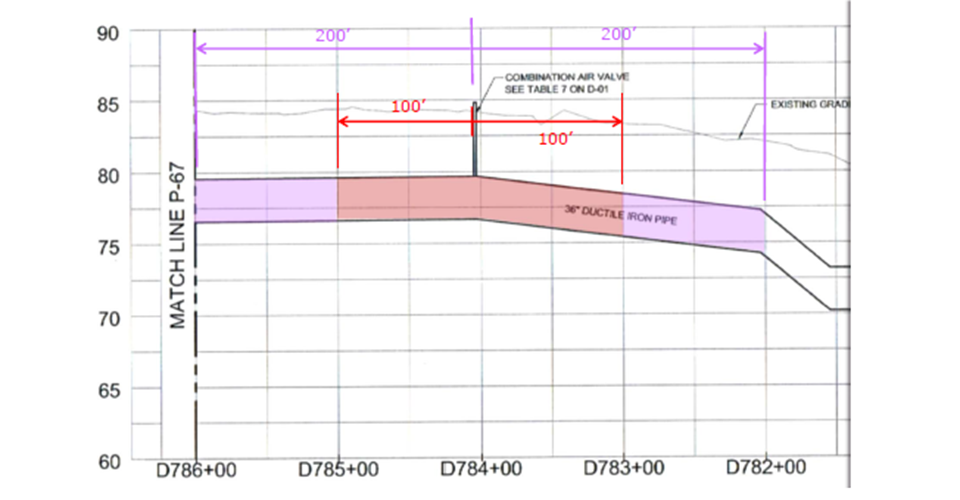

H2S is going to congregate at high points. In pressure systems, these high points will have air release valves (ARV). While there is no written rule as to how much of the line around these high points must include specialty linings, a rule of thumb that many engineers and municipalities agree with is roughly 100 feet either side of the high point. If you want to have more of a safety factor, then maybe you would want to specify that 200 feet either side of the high point receive a specialty lining.

To reiterate, there is no written rule as to how much of the line on either side of the high point needs to be lined. The point is that just because H2S exists in the line, you do not have to require that the entire line must receive a specialty lining. Utilizing this commonsense approach allows you to have a line that works as designed at a cost that could save the utility and ratepayers significantly.

We Are Here to Assist

I hope that this blog has helped you gain a better understanding of when you can and cannot utilize cement-lined ductile iron pipe for wastewater applications. If you have any questions regarding an upcoming project or would like help assessing any issues that might arise in a line that is already in service, please contact your local McWane Ductile Sales Representative or one of the McWane Ductile Product or Regional Engineers.