How Do Engineers Impact the Waterworks Industry?

It’s National Engineers Week (EWeek). Founded by the National Society of Professional Engineers in 1951, (EWeek) is dedicated to promoting careers in engineering and technology to develop a diverse and well-educated future engineering workforce. This #IronStrong Blog spotlights the importance of engineers and how they impact the waterworks industry.

The ever-evolving waterworks industry demands the skills of engineers from numerous disciplines. Engineers play a critical role in improving water quality and modernizing distribution systems to provide a reliable water supply critical for strong, healthy communities consisting of farms, businesses, hospitals, schools, homes, and more.

What are the Key Roles Engineers Play in the Waterworks Industry?

Some prominent roles of engineers in the waterworks industry include:

- Manufacturing: Engineers in the manufacturing process serve key roles in guaranteeing the integrity of the product for use in delivering safe drinking water and doing so efficiently.

- Planning: Short- and long-term plans for utilities are developed to identify future needs strategically. Hydraulic efficiency, pipe resiliency, and estimated service life are just a few factors that might affect a sustainable solution project.

- Design: Once strategic projects are decided upon, a detailed design begins. Engineers assist designers in identifying applicable products for the design, benefits derived from those products, and assisting in unique scenarios requiring specialty applications.

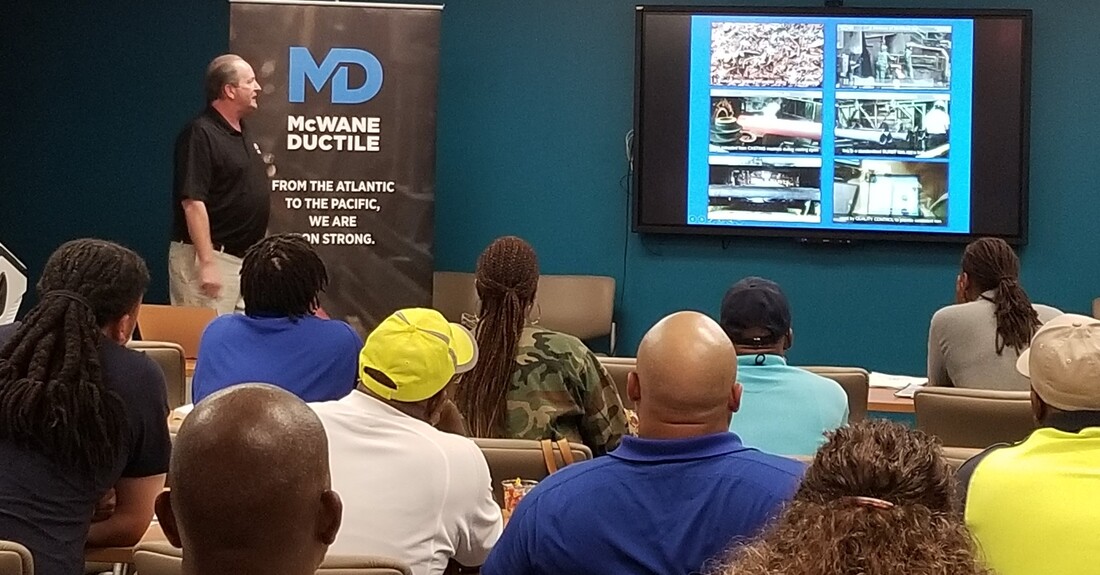

- Construction: Engineers assist utilities and contractors through education in the proper installation methods of the product(s) to avoid future failures that will be costly and could adversely affect customers.

- Operation: Serving on various standard councils, engineers review and develop material specifications to ensure users proper and economical service from the product. This also includes assisting the users' understanding of the product's attributes, allowing for the educated selection of materials to benefit the users' operation after installation.

What Are Some Key Responsibilities of McWane Ductile Engineers?

Many water utilities are making more environmentally conscious decisions, such as choosing long-lasting products made from eco-friendly, affordable materials, reducing water waste, and improving energy savings. These efforts often translate to lower water costs for the end-user.

As the waterworks industry evolves, so do our customers’ needs and preferences. Within McWane Ductile, our engineers are vital to meeting customer demand for sustainable, durable, environmentally friendly products.

They are integral in assisting utilities with determining major water system improvement projects and programs. They play a hands-on role in training utility crews when installing waterworks products to ensure the proper construction of the pipeline system. They provide continuous instruction so projects run smoothly to bring the end-customer the water they rely on daily.

McWane Ductile employs numerous team members and senior staff with engineering backgrounds throughout the company. There are currently 42 designated roles, including:

- 3 Regional Engineers

- 2 Product Engineers

- 2 Engineering Managers

- 16 Mechanical

- 8 Electrical

- 1 Project/CAD

- 2 Environmental

- 2 Civil

- 2 Computer Science

- 1 Chemical

- 2 Industrial

- 1 Architectural

These folks are required to think logically, solve problems, and have the technical skills to accomplish many projects, both in the foundry and in the field. Some of these projects include, but are not limited to:

- Designing for the manufacture of new products, such as Ductile iron pipe with resilience to seismic activity, flood, and fire

- Developing greener, more environmentally friendly products and processes

- Ensuring the safety of the environment and ecosystems directly associated with each manufacturing facility

- Creating safer working environments and procedures for employees

- Improving ergonomics and developing tools employees need to perform their duties better

- Improving efficiency in the foundry and the field

- Studying processes and developing continuous improvement initiatives

- Troubleshooting and improving hardware/software interfaces

- Maintenance and upkeep of equipment

- Designing and overseeing the construction of manufacturing equipment and facilities

- Collaborating with water utilities to design safe, efficient water pipeline systems

Q and A with McWane Ductile’s Engineers

We asked some of our engineers to participate in a quick question-and-answer session. They were asked three questions:

Q1: What is your role at McWane Ductile?

Q2: How do you see engineers playing an essential role in the future of water?

Q3: What advice do you have for high school and college students interested in pursuing a career in engineering?

Let's meet some of our engineers and find out how they responded.

Dave McKee, Engineer Manager (Mechanical Engineer)

A1: As Engineering Manager, I work with a team of engineers to complete projects to improve safety, quality, and production. We are always looking for innovations to improve our plant and be the leader in manufacturing Ductile iron pipe and pole products.

A2: Everyone needs water for sustainability. As the population grows and older systems require replacement, the demand for engineers to develop water products and systems to meet the needs will be high.

A3: Engineering is a very rewarding field of study; it offers many avenues for future employment. If interested in engineering, pursue internships and co-ops to help you gain experience and learn the different disciplines.

Connor Mitchell, CI & SPS Manager (Industrial Engineer)

A1: My group and I conduct quality audits, evaluate processes, and perform analysis’. We seek to identify waste, focusing on consistency and reducing variation.

A2: Water is a necessity that will always need to be transported. The need for engineers will continue to grow to improve the efficiency and technology of the water infrastructure in the United States continually.

A3: Engineering is so satisfying. Whether designing something new, improving a process, or making someone's job easier, these projects go a long way to affect the end-user positively.

Ken Rickvalsky, ENV SP, NACE CT, National Product Engineer (Petro-Chemical Engineer)

A1: I provide whatever assistance is needed to take a project from idea to design, to installation, to providing clean water/collecting sewage for treatment safely for generations.

A2: Engineers, to me, are the referees of the game called waterworks. Our job is to bring action to ideas and corral varied thoughts into creating reliable, efficient utilities.

A3: Understand that whatever “engineering degree” you earn certifies to others, employers especially, that you are trained to think through problems, not fear or recoil from them. The rest, proving yourself, is applying that skillset across time to validate the degree obtained.

Roy Mundy, Professional Engineer, ENV SP, Assoc. DBIA (Civil Engineer)

A1: My role as Senior Regional Engineer for McWane Ductile is to assist our clients or potential clients in value engineering of pipeline projects, specialty designs, specification development, project facilitation through engineering assistance, and education through engineering presentations and discussions relating to attributes of Ductile iron pipe in comparison to other respective pipeline materials utilized primarily for drinking water and wastewater infrastructure.

A2: The design, construction, and operation of our country's drinking water and wastewater infrastructure has long been a vital element to our quality of life. To ensure this key element continues to be maintained and even enhanced, new standards are continuously being reviewed, enhanced, and implemented, evolving technologies are instituted, and supporting infrastructure is put in place.

Engineers provide the vital link in assuring all of these components are properly planned, designed, and constructed in such a way as to provide efficient, effective, and sustainable facilities that not only deliver drinking water and wastewater that will meet current standards but do so to the benefit of respective customers regarding cost-effectiveness, product safety, and environmental integrity.

A3: How often do we cross a bridge, not even considering our safe passage to the other side? How many times do we draw a glass of water from our tap with all lights out in the middle of the night, never giving thought to the water’s quality? These two small examples illustrate the value of an engineering career to our society.

A substantial portion of the fabric of our country and that of nations worldwide is woven through the education, credentials, and experience of the engineering profession. Such a career will find that engineers will always be needed, valued, and respected.

In Summary

Forward-thinking engineers help us achieve our mission of building iron strong utilities for generations. Whether they work in one of our offices or out in the field, engineers across a wide range of disciplines – from electrical to civil to mechanical –are at the heart of each project and initiative that helps ensure our foundries run smoothly and our customers have the products and service they rely on every day.

Interested in Engineering?

Students interested in engineering are encouraged to pursue internships or co-op opportunities to receive hands-on experience, develop their professional skills, and better understand the career paths that align with their strengths and interests. McWane Ductile offers year-round internships and co-ops.

Currently, McWane Ductile employs or interns approximately 50 engineers across our U.S. facilities with open positions. Visit McWaneDuctile.com/AboutUs/Careers for information on current intern/co-op and employment opportunities. #NationalEngineersWeek