In regions prone to seismic activity, the resilience of critical infrastructure plays a pivotal role in public safety.

Among essential systems, water distribution networks are particularly vulnerable during catastrophic earthquakes, where ground movement and soil liquefaction can cause widespread pipe failure.

Ductile iron pipe (DI pipe), however, has emerged as a highly reliable material due to its superior properties, joint flexibility, and proven performance in past seismic events.

This #IronStrong Blog examines how the unique design and strength characteristics of DI pipes contribute to their remarkable ability to withstand the intense stresses of major earthquakes, ensuring continuity of service when it is needed most.

Seismic Resilience

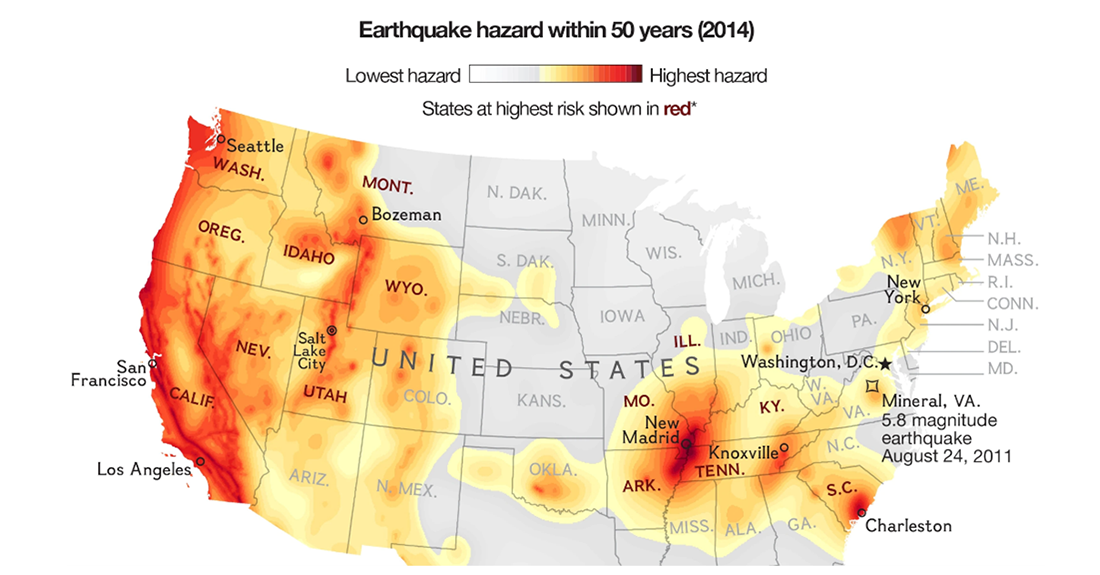

According to the U.S. Geological Survey, more than 4,500 earthquake events of a magnitude of 2.0 or greater occurred in North America in 2017.

Most of these were minor, but 31 measured 5.0 or above on the Richter scale. At 5.0, the energy released by the Earth is the equivalent of 200 tons of TNT.

The experiences of utilities in the aftermath of the more significant earthquakes led to the conclusion that, in seismic events, there is no better pipe material available than Ductile iron pipe.

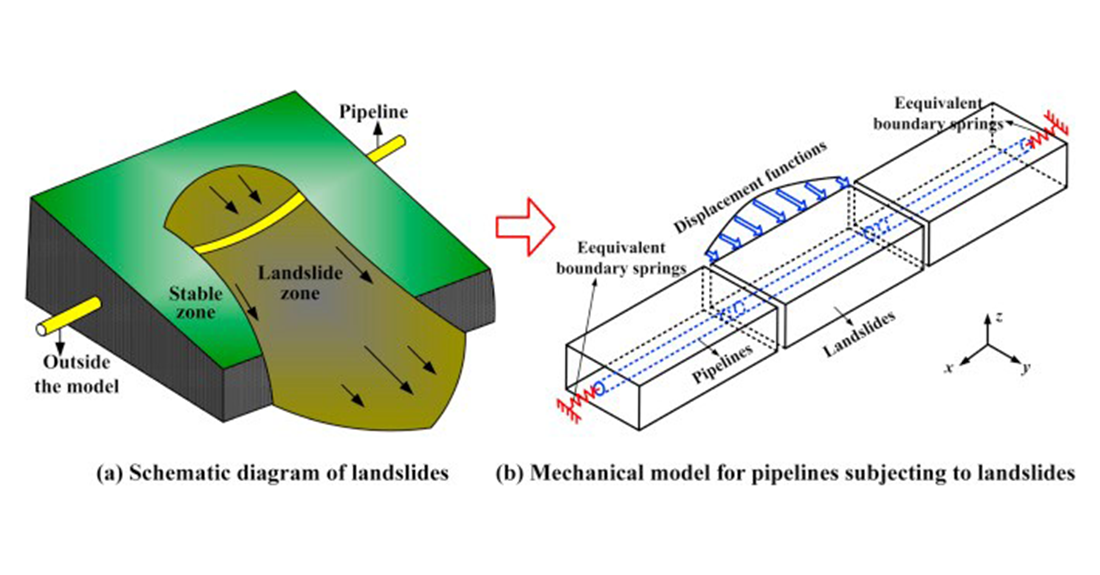

Designing or retrofitting for seismic resilience can play a crucial role in mitigating damage to buried potable water and wastewater pipelines caused by seismic hazards. These hazards can include:

- Earthquake zones

- Unstable slopes

- Liquefaction zones

In earthquakes, liquefaction refers to the process in which saturated or partially saturated soil temporarily loses strength and behaves like a liquid due to strong ground shaking.

How Earthquakes Impact Pipelines

These seismic events can wreak havoc on buried pipelines if the pipe material is unable to:

- Withstand external loads and/or trench failure

- Provide excellent joint deflection

- Handle significant compression or tension on the pipeline

The Advantages of Ductile Iron

Robust pipe materials such as Ductile iron provide a higher level of seismic resilience to:

- Maintain fire protection

- Reduce the potential of shearing on service connections

- Prevent cross-contamination or force main spills

Why Ductile Iron is the Right Choice for Seismic Resilience vs. Alternative Materials

Restrained joint Ductile iron pipe is the standard for seismic resilience, as listed in the International Standard ISO 16134, due to its:

- Minimum tensile strength of 60,000 psi

- High joint deflection

- Strain capacity compared to alternative pipe materials

Restrained joints and next-generation fittings also provide extremely high axial capacity to accommodate tension or compression on the pipeline.

Case Studies: Strength Against Earthquakes

The 1995 Great Hanshin (Kobe) Earthquake

The Kobe Earthquake struck Japan with a magnitude of 6.9, causing widespread devastation, including severe damage to lifeline infrastructure such as water and gas pipelines.

A comparative evaluation of pipeline performance revealed that Ductile iron pipe demonstrated exceptional resilience under seismic stress, particularly when compared to other materials, such as cast iron and polyvinyl chloride (PVC).

Key Observations:

- Thousands of failures were reported in brittle cast iron and older steel pipelines.

- Areas equipped with newer Ductile iron pipe — especially those with restrained or flexible joints — showed significantly fewer failures.

- According to the Japan Ductile Iron Pipe Association, DI pipe with earthquake-resistant joints experienced a failure rate of just 0.001 per kilometer, compared to over 2.0 per kilometer for other materials (JDIPA, 1995).

The flexible joint design enabled the pipe system to absorb seismic energy and remain intact, thereby maintaining essential water supply lines for firefighting and emergency services in certain districts.

Global Influence

The successful performance of Ductile iron pipe in Kobe prompted further adoption of seismic-resistant DI pipe systems throughout Japan and has influenced seismic design practices globally.

Utilities in earthquake-prone regions, such as:

- California

- The Pacific Northwest

- The Midwest

…are adopting DI pipe with earthquake-resistant features as part of their resilience strategies.

Municipalities recognized the importance of investing in durable infrastructure capable of withstanding future seismic events, leading to widespread implementation in high-risk zones.

Summary

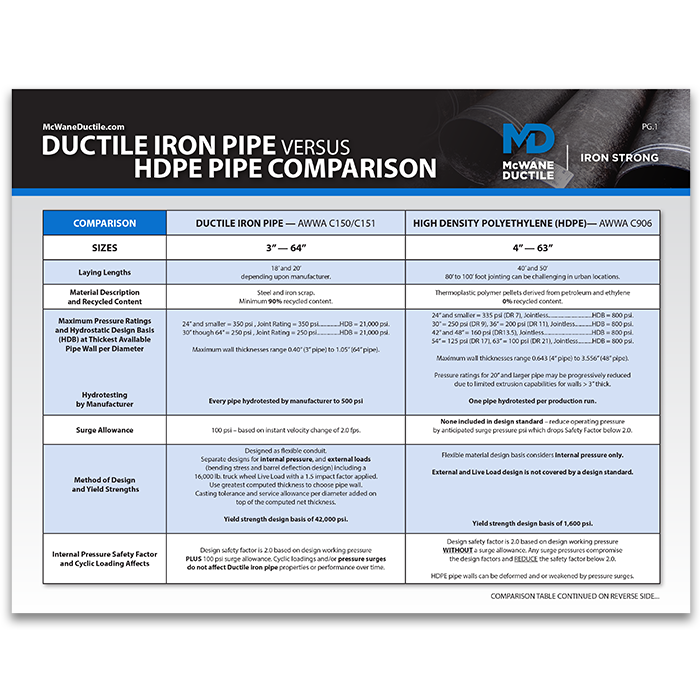

Not all materials are created equal, so selecting the proper pipe material is the first step in ensuring that vital infrastructure is protected and safe in the event of a catastrophic event.

With a tensile strength of 60,000 psi, Ductile iron is far superior compared to the tensile strength of alternative materials such as PVC and HDPE.

However, selecting DI pipe is not just a matter of efficiency; it’s a critical investment in resilience and public safety.

Its superior strength, flexibility, and proven seismic performance make it a preferred choice for water infrastructure.

Do you have questions about seismic resiliency?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is well-equipped to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

Ductile Iron Vs. HDPE Pipe Comparison Sheet

Ductile iron and HDPE (high-density polyethylene) pipe are vastly different. To further explore the differences, download our handy tip sheet or contact your local McWane Ductile representative for project-specific support.

References

- American Water Works Association. (2005). Buried No Longer: Confronting America’s Water Infrastructure Challenge.

- Ductile Iron Pipe Research Association. (n.d.). Longevity of Ductile Iron Pipe. https://dipra.org/about-Ductile-iron-pipe/longevity

- Ductile Iron Pipe Research Association. (2021, August 17). DIPRA Minute: Proven Resilience of Ductile Iron Pipe.

- Japan Ductile Iron Pipe Association. (1995). Report on the damage to water supply pipelines in the 1995 Hanshin-Awaji earthquake.

- United States Environmental Protection Agency. (n.d.). Creating Resilient Water Utilities.

- United States Environmental Protection Agency. (n.d.). Risk and Resilience Assessment Requirements and Assistance Resources.

- United States Environmental Protection Agency. (n.d.). Baseline Information on Malevolent Acts for Community Water Systems.

- United States Environmental Protection Agency. (2018, March 26). Surviving the Quake [Video]. YouTube. https://youtu.be/U_098V40t6E

- Xie, X., Symans, M. D., O’Rourke, M. J., Abdoun, T. H., Ha, D., O’Rourke, T. D., Palmer, M. C., Jezerski, J., & Stewart, H. E. (2017, November 20). Local buckling of buried HDPE pipelines subjected to earthquake faulting: Case study via numerical simulations and experimental testing. Journal of Pipeline Systems Engineering and Practice. https://doi.org/10.1061/(ASCE)PS.1949-1204.0000301

Additional Resources

- Liquefaction during the 1906 San Francisco earthquake. (2011, April 6). [Video]. YouTube. https://youtu.be/qmVYbjiNWds

- Civil Engineering Magazine (September 2019). Resiliency. [Includes useful maps.]