In a recent #IronStrong Blog published in September 2024, we discussed, in detail, how to measure horizontal distances between offsets within a Ductile iron (DI) pipeline segment. This blog will continue that discussion by addressing how to calculate the vertical distance between DI pipeline offsets.

Why is it important to calculate elevation changes?

Vertical distances, like horizontal distances, can be deceiving. They are typically encountered when a Ductile iron pipeline changes elevation to avoid an existing obstruction, such as another underground utility line. As mentioned in our previous blog, the typical line is designed to overcome thrust forces by utilizing Mechanical Joint fittings with wedge action retainer glands and Tyton Joint® pipe with locking gaskets. This system allows for some flexibility in the field.

Knowing the exact distance when ordering and assembling a project utilizing TR Flex® Restrained Joint Pipe and manufactured TR Flex® Restrained Joint fittings is critical as these components fit together like a jigsaw puzzle. As previously noted, the distance between offsets is important in both cases, as it is always best to “measure twice and cut once” when working on a project.

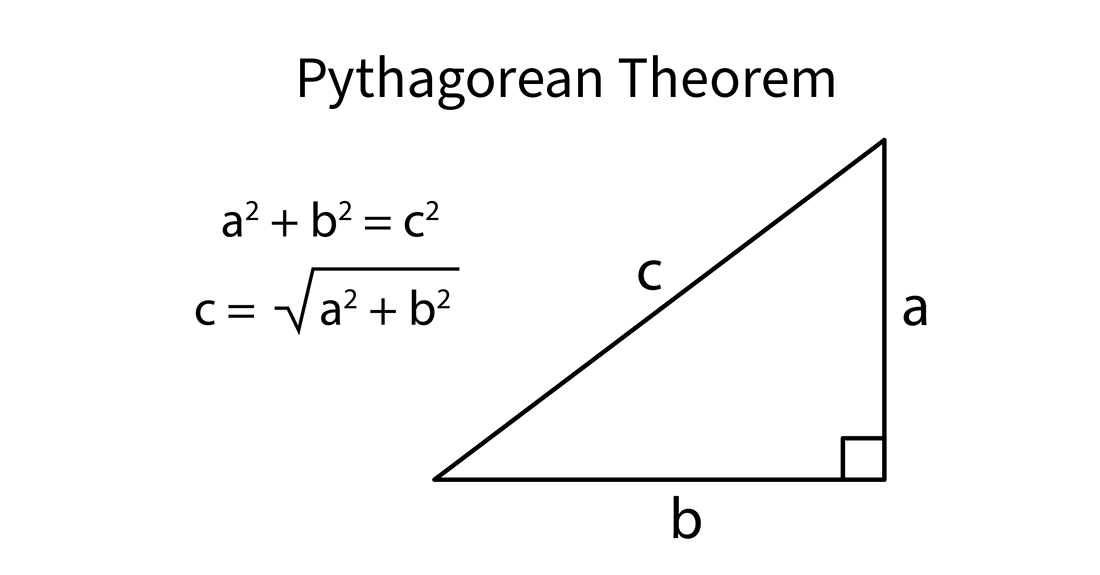

The Pythagorean Theorem (a²+b² = c²)

Before discussing how to calculate the distance when an elevation change is required, let’s quickly recall what we learned about applying the Pythagorean Theorem during our blog post about horizontal changes in direction.

- This equation can calculate the distance between two fittings, regardless of whether they are horizontal or vertical.

- This equation is used to find the length of a line in a right triangle.

- In most cases, the values for “a” and “b” can easily be obtained from the plans, and we need to calculate the distance or “c” value.

- The “a” (x-axis) is the direction in which the line is traveling or the run of the line. The ”b” (y-axis) is the change in direction of the line rising or falling.

Vertical distance between fittings and offsets (Profile View)

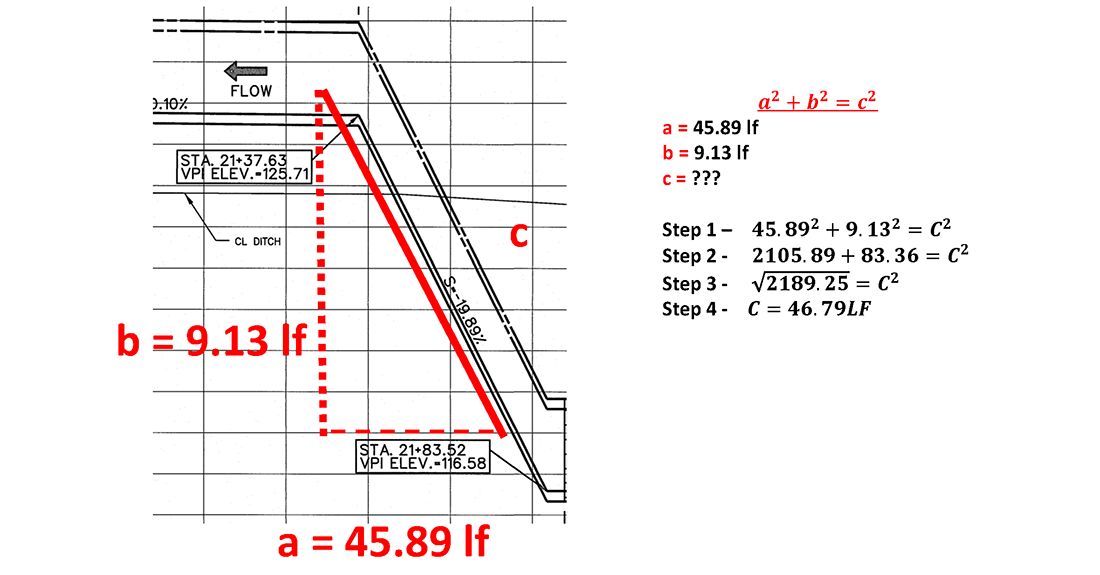

Essentially, you will use the same process to calculate the vertical distance between the fittings as you were taught in our previous blog to calculate the horizontal distances. The variable here is that one fitting is now at a higher elevation than the other instead of being situated horizontally. It is still possible to use the Pythagorean Theorem (a²+b² = c²) to calculate the distance of the unknown.

In the above example, we are determining the “c” measurement between the change in elevation of the fittings to be 46.79 lineal feet, but how did we get here?1

We arrived at the distance of “a” to be 45.89 lineal feet, which is the straight-line distance derived from the station numbers shown on the plan page. (Sta #1 21+37.63 to Sta #2 21+83.52)

Finally, the value of “b” equals 9.13 lineal feet. This value represents the difference in elevation of the fittings as shown on the plan page. (Sta #1 Elev. 125.71 to Sta #2 Elev. 116.58)

Now that we have values for “a” and “b,” we can calculate the distance between the upper and lower bends or the “c” of our equation.

As shown in our diagram above, we take our “a” (45.89) and square it to arrive at 2105.89. Finally, we take our “b” (9.13) and square it to arrive at 83.36.

2105.89 + 83.36 = c²

To solve our equation for c², we must add the left side of the equation together and then take the square root of that number. In other words, 2105.89 + 83.36 = 2189.25, and the square root of 2189.25 is equal to 46.79, which is the value of the “c,” the distance between the higher and lower fittings in our example.

Key considerations within a set of plans to determine the distance of a vertical offset

As every set of plans is drawn differently, it isn't easy to cover every possible variable that you may need to look out for, but below are two of the more common ones to at least become familiar with when trying to calculate the distances between fittings and accessory items within a Ductile iron pipeline layout.

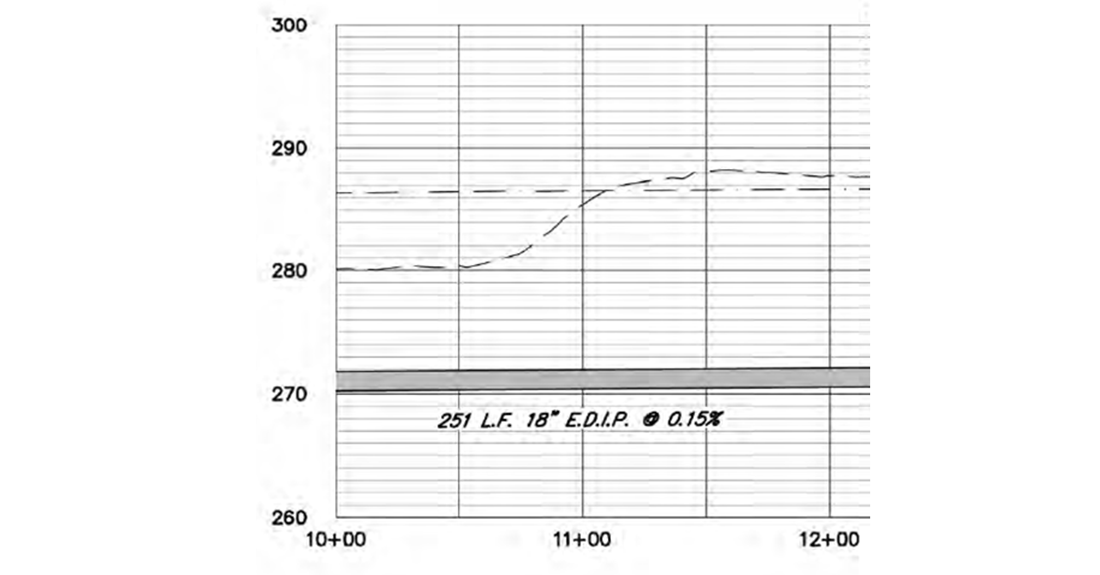

- Profile view – It is important to mention that the scale for the drawings is typically different for the horizontal runs of pipe versus the vertical elevation changes in the pipeline. This information can almost always be found within the profile view of the drawings. The horizontal scale would be shown at the bottom of the profile, running from left to right, showing the major station numbers and a series of one-inch blocks in between. Each of these blocks represents a certain distance based on the scale. The example plan set below shows that each black hash mark may represent 50 lf. The vertical scale is shown on the left, right, or both sides of the profile view. The vertical scale will be similar to the horizontal scale, except it typically has a shorter distance between the noted elevations. Also, instead of showing the Station Numbers, you will see the elevation above (or below) sea level on a vertical scale.

- Why is this important? This is a very important part of estimating, bidding, and purchasing because if you simply base the distance between vertically offset fittings on the straight-line distances as shown on the plan/profile pages, you will typically come up short, regardless of whether you are looking for the distance between horizontal, vertical, or combination fittings. When calculating the distance for installation, you must subtract the lay lengths of both fittings from the calculated “c” distance.

Conclusion

Using the Pythagorean Theorem, we have examined how to calculate the lay length for vertical offset fittings in the profile view. If you do not want to do the math, you may find a right-angle triangle calculator on the internet and bookmark it to do the math for you.

This information will enable you to calculate your estimated footage better on your next Ducitle iron pipeline project. Remember, if you have difficulty calculating your project's footage, please feel free to reach out to your local McWane Ductile Sales Representative or McWane Ductile Product Engineer for assistance.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is equipped with the expertise to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

References

- West Harris County Regional Water Authority, 24-inch Water Main from Fry Road Contract 35 tie-in along HCFCD U120-00 to Contract 38 tie-in, Contract #37, Sheet No. 24 of 147.