Nowadays, it seems more and more municipalities and utilities are requiring contractors to hire someone to pressure wash Protecto 401TM -lined ductile iron pipe before they will accept the pipe into their system.

Why is this being done?

Typically, the municipality requires this post-construction to ensure all debris is out of the line as well as catch any depressions or “sags” in the line. The utility will also do this prior to the contractor’s warranty expiring in order to discover any settling of the line, sags, or defects that may appear.

Is there a proper way of doing this?

Yes, there is. An extensive study sponsored by the Ductile Iron Pipe Research Association (DIPRA) and its member-companies was conducted to develop the proper procedure of pressure washing Protecto 401-lined ductile iron pipe without damaging the lining.

If not done properly, damage to the lining could shorten the lifespan of the line, causing the municipality/owner to incur thousands of dollars in repairs and/or a total replacement of the line long before they anticipated.

What damage could this do to the line?

If not done properly, pressure washing could generate what appears to be flaking in the lining and/or a “spider web” effect. At worse, it could instigate delamination of the lining from the pipe wall altogether.

What is the procedure?

Below are the guidelines to follow for pressure washing ductile iron pipe with Protecto 401 and/or cement lining. This procedure was developed with and accepted by the leading epoxy providers to the water and sewer industry:

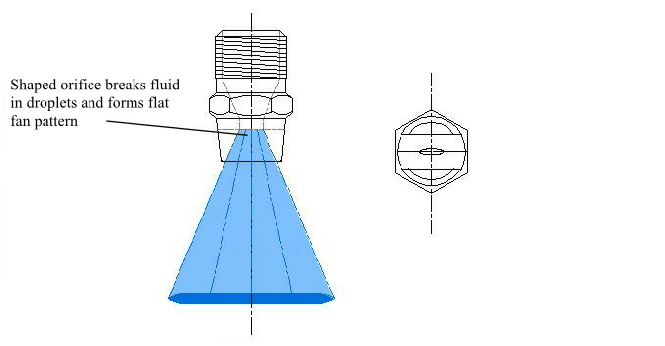

- The nozzle shall be configured with fan jets only (no round jets).

- The fan jets should be oriented at a maximum angle of 30 degrees to the pipe wall.

- The nozzle shall be a minimum of 2-inches standoff from the pipe surface.

- The nozzle assembly shall be self-rotating and incorporate a rotational control mechanism with a target speed of 30 rpm.

- The water pressure at the nozzles shall be no more than 2500 PSI for Protecto 401-lined pipe and 1800 PSI for cement-lined pipe.

- The nozzle assembly shall have non-abrasive wheels and/or UHMW (ultra-high molecular weight) polyethylene skids positioned so the nozzle assembly does not contact the lining of the pipe at any time.

- The nozzle assembly shall continually move when pressure washing with no hesitation in the pipe.

- All hose couplings, hoses, etc. shall be smooth to facilitate movement across the pipe joints without creating damage to the lining.

Why should we follow this procedure?

If this procedure is not followed properly and damage is done to the lining, then who is to blame? Is it the contractor, the manufacturer, or the sub-contractor who cleaned the line? All kinds of questions and delays may arise when putting the line into service.

We strongly recommend that all municipalities/owners who require their sewer lines to be pressure washed incorporate the above procedures into their standard specifications and to enforce these specifications as they do all others.

Where can I find a copy of the proper procedure?

You can simply click on the download button below to recieve a handy PDF Tip Sheet with guidelines OR you can go to the Ductile Iron Pipe Research Association’s website at www.dipra.org to find many technical documents.

Need to clean your specialty-lined Ductile iron pipe? Use this tip sheet to safely and effectively pressure-wash Protecto 401 and/or cement lined pipe.

Need assistance with your water infrastructure project?

McWane Ductile offers multiple services for our customers extending far beyond manufacturing ductile iron pipe. From design to installation, we take great pride in providing education and assistance to water professionals throughout the water and waste water industry.

Check out all our digital offerings: