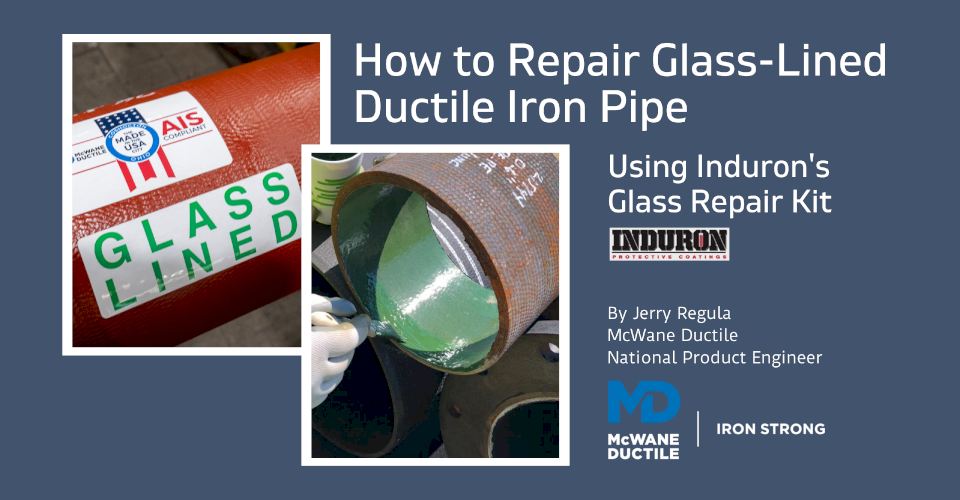

When discussing Ductile iron pipe (DI pipe) in corrosion-resistant applications, glass-lined DI pipe often comes to mind. Glass lining has often been the specified lining for DI pipe in sewer and chemical resistant applications.

Common uses for glass-lined pipe are for situations such as a sludge line in a wastewater treatment plant or when harmful chemicals are present in the pipeline. There may be occasions in the field when patching of the glass lining may be necessary. Check out this link for added information What Pipe Linings Are Best for Sewer Applications? By Dusty Henderson.

In this blog, we will cover how to patch the damaged area of glass lining of the pipe that may have occurred due to the field cutting process or improper handling.

After reading this article, you will have the knowledge needed to complete an in-the-field patch using Induron’s Glass Repair Epoxy Kit.

Avoiding Patching in the First Place

Before we talk about how to patch, we need to talk about how to prevent damage to the lining. Here are a few tips to help avoid patching glass-lined pipe in the first place.

- Components of the wastewater system such as piping, fittings, valves, etc. should be lifted using a proper lifting device on the Outside Diameter of the pipe. DO NOT use a chain or a steel cable on the inside of the product. See this helpful Iron Strong blog on how much DI pipe weighs and why it matters by Gary Gula.

- Field cutting pipe: Set the pipe on 4’ x 4’s placed on a level plane prior to cutting. This will provide a safe set-up and improve the chances of making a clean, straight cut. See this great instructional Iron Strong blog with video on how to properly cut DI pipe by Jason Barnes.

- Use the proper tools such as a file or angle grinder to remove any sharp edges after cutting a pipe or beveling a cut end.

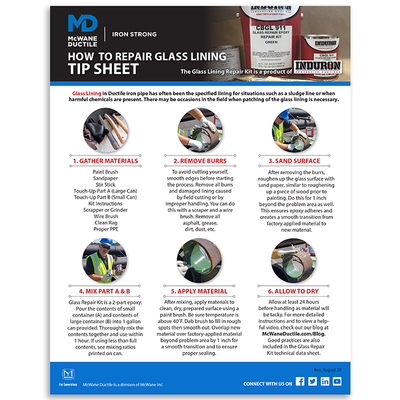

Before Starting, Gather Your Materials

Included in Touch Up Kit

- Paint Stick

- Sandpaper

- Stir Stick

- Part A (Large Can)

- Part B (Smaller Can)

- Instructions

Recommended Material

- Scrapper or Grinder

- Wire Brush

- Safety Glasses

- Gloves

Prepping for Repair

PRO TIP: The ambient temperature must be above 40 degrees Fahrenheit before patching glass lining.

- Wear proper PPE. Gloves and safety glasses are recommended. Do not repair glass-lining in an enclosed space. Included in your patch kit is a technical data sheet for more safety information.

- Smooth the edges of the pipe. Remove all the burrs that were caused by rough handling or field cutting with a file or grinder before you start the patching process. This will help ensure you do not cut yourself on loose metal flakes.

- Remove any damaged glass lining caused by rough handling or field cutting. You can do so with a scraper and a wire brush.

- After the loose material is cleaned out of the pipe, make sure to "roughen up" the damaged area and surrounding area with sandpaper, similar to roughening up a piece of wood before painting it.

- Remove all traces of asphalt, grease, dirt, dust, etc. inside the pipe.

Mixing the Kit

PRO TIP: If using less than the full amount of the content in the cans, use the ratio printed on the cans to ensure a proper mixture.

- Included in Induron’s Glass Repair Epoxy Kit, you will find two cans of glass lining touch-up material; one large can is marked A and one smaller can is marked B.

- Due to the glass lining patch kit being a two-part epoxy, you will mix the contents of can A and can B into the larger empty can. This will allow room for mixing and reduce the chance of spilling any contents.

- After adding the contents of two cans, be sure to mix the batch thoroughly.

- After mixing the batch, the material should be used within one hour.

Applying the Epoxy

- Once the surface to be repaired is clean and prepped, and the Glass Repair Epoxy is thoroughly mixed, Apply the epoxy using the clean brush provided in the kit.

- Apply the material to the prepared surface with a paintbrush using a dabbing motion to fill the bare surface without getting too much glass lining material on the surface.

PRO TIP: Overlap the newly brushed material over the factory-applied material about an inch beyond the problem area. The application of more than one layer may be necessary to ensure proper thickness and sealing.

Some day you may have to repair damaged glass lining. Do it right with our free Glass Lining Repair Tip Sheet from McWane Ductile

Additional Information

- Glass Repair Epoxy should be used only after the pipe/fitting is lined with the glass lining.

- Glass Repair Epoxy can be used on bare surfaces and over top of glass lining.

- DO NOT apply glass lining over the Glass Repair Epoxy.

- DO NOT apply glass lining Glass Repair Epoxy on wet or frozen surfaces.

- MSDS sheets are available upon request.

Summary

With proper care and attention to detail, the need for repair can be avoided all-together. IF YOU DO happen to damage your glass-lined Ductile iron pipe, you can now feel confident knowing what it takes to patch the small areas affected. Just remember the three easy steps: Prep-Mix-Apply.

We're Here to Assist

We are here to assist with team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.