A Sustainable Solution for Chandler, Indiana

The town of Chandler, Indiana, recently needed to enhance its water supply system to end users—particularly to better serve elevated storage tanks and provide critical redundancy for medical and educational facilities. Their solution? A 41,000-foot installation of 24-inch Ductile iron (DI) pipe, which not only addressed the town's infrastructure needs but also qualified for Green Project Reserve (GPR) financing through Indiana’s State Revolving Fund (SRF).

Why did Chandler's project qualify for this preferred funding? The environmental advantages of Ductile iron pipe played a key role. Made predominantly from recycled materials—including structural and automotive steel scrap—DI pipe is one of the few infrastructure products with strong pre- and post-consumer recyclability. Chandler and its engineer built a compelling business case around this fact, positioning DI pipe as an environmentally innovative material eligible under GPR.

What Makes Ductile Iron Pipe Green?

According to the U.S. Environmental Protection Agency’s Green Project Reserve Guidance (available at SRF.IN.gov), GPR eligibility includes four key categories:

- Green Infrastructure

- Water Efficiency

- Energy Efficiency

- Environmentally Innovative

Ductile iron pipe fits squarely into the Environmentally Innovative category.

It Starts with Recycled Content

DI pipe is primarily composed of recycled iron and scrap steel. This includes:

- Shredded engine blocks

- Brake rotors

- Automotive frames

This specific use of recycled content is listed in Section IV, Item 3 of the SRF checklist as a qualified example requiring a business case. By choosing DI pipe, Chandler's engineers demonstrated that a significant portion of the project costs were allocated toward environmentally innovative materials that reduced environmental impact and carbon footprint.

How Chandler Made the Case

To qualify for GPR, Chandler had to provide a documented business case showing how the DI pipe:

- Met GPR eligibility criteria

- Used recycled materials

- Reduced emissions by limiting the need for truck-hauling imported bedding material

- Supported the reuse of native soils for backfill

- Contributed to energy-efficient system performance

In fact, DI pipe has a significantly larger inside diameter than alternative materials, such as PVC, HDPE, or steel. This means:

- Lower friction loss in the system

- Improved pump efficiency

- Reduced energy consumption

- Lower operational costs over the long term

Moreover, the larger internal diameter allows for future system growth without needing costly replacements.

Project Design & Documentation

The engineering team began by requesting a budget quote from a DI pipe supplier for material costs. To this, they added:

- Engineering design fees

- Construction contingencies

This total helped illustrate that the environmentally innovative portion of the project (the DI pipe) represented a significant share of the overall project cost—a key requirement under SRF guidance.

They included this breakdown as an appendix to the project’s Preliminary Engineering Report (PER), which was submitted to the SRF prior to bidding.

The result? Indiana’s SRF agreed with Chandler’s business case and confirmed the project qualified for the GPR incentive.

Bidding Requirements & Contractor Documentation

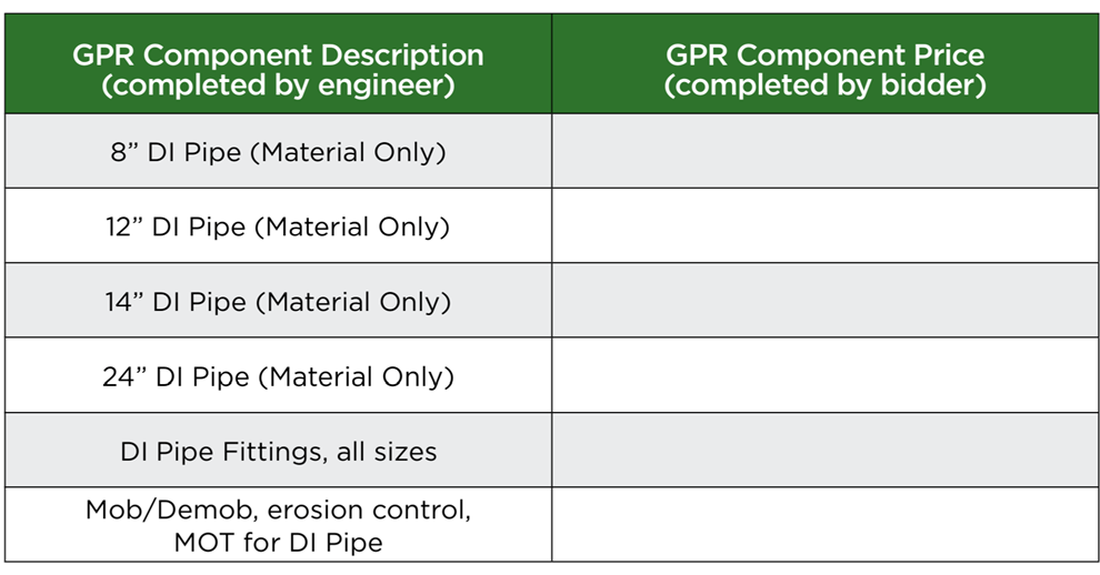

To maintain transparency and ensure compliance with SRF requirements, the project team included mandatory forms in the bidding documents. Contractors and engineers were required to:

- Complete a GPR cost breakdown

- Certify that actual GPR material costs matched submitted estimates

- Submit supporting documentation to SRF with each payment request

This ensured SRF could verify how much DI pipe had been installed or delivered onsite during each phase.

Real Incentives: Real Savings

With the contractor’s bid in hand, the town was eligible to apply the GPR incentive to reduce its interest rate on the SRF loan. Here’s how it worked:

- Total Project Cost: Approximately $8.7 million

- Base SRF Rate: Already favorable as of March 2023

- GPR Incentive: Reduced the interest rate by at least 0.2%

This seemingly small rate reduction resulted in substantial debt service savings over the life of the loan.

As of August 2024, 97% of the DI pipe qualifying for the GPR incentive had been either installed or delivered onsite.

Looking to Qualify for GPR Incentives on Your Project?

If you’re planning a water infrastructure project and want to explore options for Green Project Reserve or State Revolving Fund financing, McWane Ductile can help.

Many of our team members have:

- Managed water utility systems

- Worked in engineering consulting firms

- Decades of field experience in pipeline construction and operations

Let us help you develop a solid business case and navigate funding options. Contact your local McWane Ductile representative or visit us online at McWaneDuctile.com.

Final Thoughts

Chandler, Indiana’s successful use of Ductile iron pipe is a prime example of how choosing sustainable materials can pay dividends—not just for the environment, but for the bottom line. By investing in recycled and recyclable infrastructure, municipalities can:

- Improve system longevity

- Reduce operational costs

- Qualify for valuable state and federal incentives

Green infrastructure isn’t just a buzzword—it’s smart planning.