Critical to DI Pipelines

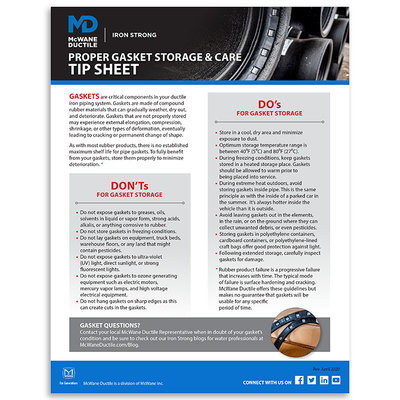

Gaskets are critical components in your ductile iron piping system. To get the full benefit of your gaskets, they need to be stored in a manner that minimizes deterioration. We don’t always work in favorable conditions, so no matter if you are in the field or in a warehouse, utilizing the best storage practices and locations are key to the performance and the effective lifetime of your gaskets.

In this article, we will cover some guidelines on how to store and care for your gaskets. We will cover the “what to do” as well as the equally important ”what not to do".

Consider This

Gaskets are made of compound rubber materials. Some of these materials can gradually weather, dry out, and deteriorate. Gaskets that are not properly stored may experience external elongation, compression, shrinkage, or other types of deformation, eventually leading to cracking or permanent change of shape.

What to Do

Below are a few simple guidelines for how best to care for your gaskets.

- Store in a cool, dry area and minimize dust exposure.

- Keep gaskets out of the elements. Avoid leaving gaskets out in the rain or on the ground where they can collect unwanted debris, or even pesticides..

- Storage of gaskets in freezing conditions is not recommended. When working in freezing conditions, gaskets should be allowed to warm prior to installation and usage.

- Pro Tip: When working in colder climates, keep gaskets stored in a running vehicle or other heated storage place.

- During extreme heat outdoors, avoid storing gaskets inside pipe. Same principle as with the inside of a parked car in the summer. It’s always hotter inside than it is outside.

- The optimum storage temperature range is between 40⁰F (5⁰C) and 80⁰F (27⁰C).

Take care of critical components of your pipeline system! Avoid the harmful effects of improper gasket storage with our free and handy tip sheet.

What Not To Do

Following are a few tips for what to avoid when storing and handling your gaskets.

- Do not expose gaskets to greases, oils, or solvents in liquid or vapor form.

- Avoid leaving gaskets where they may encounter fuels, grease, solvents, or anything else corrosive to rubber.

- Pro Tip: Avoid laying gaskets on equipment, truck beds, warehouse floors, or any land that might contain pesticides.

- Rubber gaskets should be protected from light, including sunlight and strong artificial light with high ultraviolet content.

- Storing gaskets in polyethylene containers, cardboard containers, or polyethylene-lined craft bags offer good protection against light.

- Rubber gaskets should be kept away from ozone generating equipment such as electric motors, mercury vapor lamps, and high voltage electrical equipment.

Things to consider if long term storage of your gaskets is required.

- Avoid hanging gaskets on sharp edges as this can create cuts in the gaskets.

- If possible, keep the gasket stored area away from large receiving doors. Cover the immediate top of gaskets from direct light exposure and dust.

- Inspect gaskets for any debris or signs of deterioration prior to installation.

- Components that have been stored outdoors for any significant time period should have the gaskets replaced before installing into a pipeline system.

Summary

With proper storage employed, the typical gasket compound of Styrene Butadiene (SBR) shipped with most DI pipe should have a shelf-life of approximately three years. Different compounds will have varying shelf-life's of up to twenty years, a subject to be covered in future Iron Strong articles. Should you have questions about the shelf-life or storage conditions of your gaskets, please contact your local McWane Representative.

Following these simple guidelines can ensure that the length of time gaskets are stored will not affect their performance when placed into service. These guidelines can also help save time and money.

Need Assistance With Your Waterworks Project?

McWane Ductile offers multiple services to our customers extending far beyond manufacturing DI pipe. From estimating to design, from production to installation, we take great pride in providing education and assistance to water professionals throughout the water industry.

Check out all our digital offerings:

- More articles and videos from our Iron Strong Blog

- The McWane Pocket Engineer

- Engage with us on LinkedIn

- Follow us on Facebook

- Follow us on Twitter

McWane Ductile, Building Iron Strong Utilities for Generations.