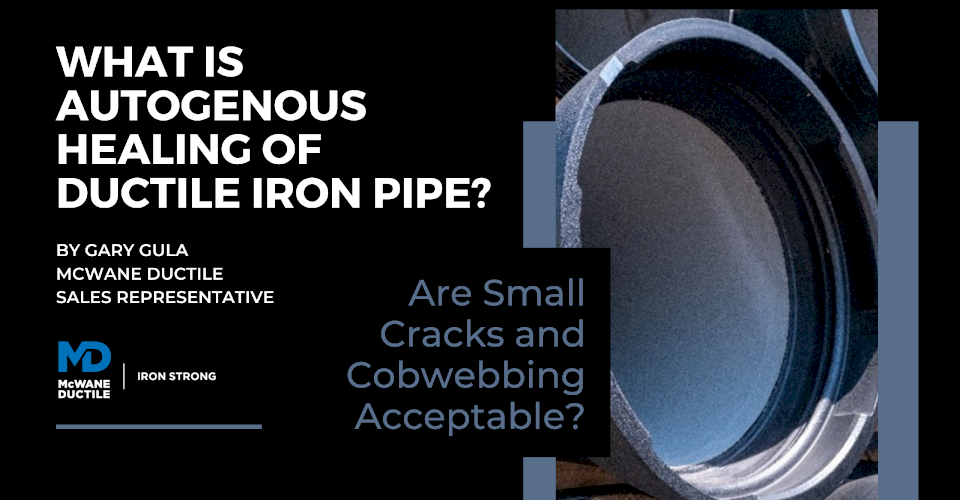

Seeing cobwebbing or small cracks in the cement lining of Ductile iron pipe (DI pipe) may raise concern for some and over the years, I’ve had some folks ask me, “Is this acceptable?” And my response is, “Yes, it is, at least to some degree.” Within this Iron Strong Blog, we will discuss Autogenous Healing (au-tog-e-nous), which is defined as the natural process of crack repair that takes place when cement linings come in contact with water.

Although there are different cement types for various applications in the world of construction, it has been said for years that there are only two types of cement – “Cement that is new and fresh, and cement that is cracked.” This statement is simply a general reference, but there is a certain amount of truth to it.

The fact is that during the curing process of any application of cement, the material will undergo changes in its physical properties as the freshly applied cement dries and cures. When applying cement to a product, the moisture used in the formation of the material disappears as the cement adheres and hardens.

History of Cement-Mortar Lined Ductile Iron Pipe

The first cement-lined cast iron pipe was installed in Charleston, South Carolina, in 1922. The pipe was lined using a projectile drawn thru the pipe, which is similar to today's lining methods, but the process has undergone some changes over time.

Before 1922, most cast iron pipe were either unlined or tar coated, which led to red, rusty water and a gradual reduction of the flow rate through the pipe. Today, the pipe are centrifugally lined, meaning the pipe are spun while being lined, to ensure a uniform thickness throughout the pipe.

What is Autogenous Healing?

Autogenous Healing is the natural process of crack repair that can occur in concrete in the presence of moisture and the absence of tensile stress. This process can simply be defined as a "self-sealing" trait that the cement lining within Ductile iron pipe naturally has within itself.

The cracking of cement-mortar linings in Ductile iron pipe occurs due to the shrinkage of the linings and temperature variations. These cracks are generally two types.

- One is surface crazing (checkerboard or cobweb pattern)

- The other being circumferential (or longitudinal) cracking

Both types of cracking are permitted and addressed within the ANSI/AWWA C104/A21.4 Standard. The surface crazing is only found in the fine sand and cement particles covering the dense mortar. They affect only the surface and are not detrimental to the serviceability of the lining. Circumferential cracks are permitted in any length, but longitudinal are limited in length by the ANSI/AWWA C104/A21.4 Standard. The general rule is that up to 24 inches in diameter, a longitudinal crack should not exceed the pipe's circumference in length.

Once in contact with water, these cracks will eventually absorb the water and, over weeks, will ultimately cause the lining to swell practically to its initial volume. During this process, the cement will ultimately knit itself back together and close the cracks.

Should I Repair These Cracks?

You will not need to repair or be very concerned about these surface cracks and crazings in almost all cases. If you encounter any, it is best to contact your local manufacturer's representative for guidance on how to proceed.

It is worth it to point out that when cutting Ductile iron pipe with (or without evidence) of cracking, the lining should indeed stay intact following the cut. If the lining is damaged or becomes dislodged due to cutting, handling, or otherwise, there is a specific procedure allowed by the ANSI/AWWA C104/A21.4 Standard for repairing that lining.

The recommended steps for repairing the lining include the following:

- Cut out the damaged lining to the metal so that the lining edges are not removed perpendicular or slightly undercut.

- Clean the damaged area and adjoining lining.

- Prepare a stiff mortar from a mixture of cement, sand, and water. The cement mortar shall contain not less than one part cement to two parts sand by volume.

- Thoroughly wet the cut out the affected area and adjoining lining.

- Apply the mortar and trowel smooth with the adjoining lining.

- The repaired lining should be kept moist by tying canvas or wet burlap over the pipe's ends or fitting for at least 24 hours. As an alternative, the repaired lining may be seal coated. Seal coat should be sprayed or brushed on within five to thirty minutes after the mortar is applied.

Click below to view a helpful McWane Ductile Iron Strong video by my colleague Jeff Houser, explaining this process.

Autogenous Healing Research and Publications

Most research done on this topic has concluded that concrete must be submerged in water for this healing process to occur. The cracks are closed by the precipitation of calcium carbonate and calcium hydroxide.

During research conducted by the Virginia Polytechnic Institute and State University, a study was performed on concrete samples in conjunction with the AWWA Research Foundation (2008). Fixed cracks containing a width of 0.25mm were submerged in waters and gently agitated for 7 to 12 months.

Periodically the researchers replaced the older water with fresh water. When samples were analyzed, they tested them for several characteristics, including strength. Some autogenous healing was evidenced by the absence of light passing through the simulated cracks.

You can find additional information regarding Autogenous Healing in the ANSI/AWWA C104/A21.4 Standard, the American Water Works Association M41 Manual titled "Ductile Iron Pipe and Fittings," as well as a Ductile Iron Pipe Research Association (DIPRA) publication titled "Cement-Mortar Linings for Ductile Iron Pipe" by Richard W. Bonds, P.E.

See these Iron Strong Blogs for more helpful information on cement-mortar lined Ductile iron pipe:

- Can I Use Cement-Mortar-Lined Ductile Iron Pipe in a Wastewater Application?

- How to Properly Pressure Wash Ductile Iron Pipe with Protecto 401 and/or Cement Lining

- What Pipe Linings Are Best for Sewer Applications?

Thank you for taking the time to read this blog. Hopefully, you have found it informative and helpful. If you have any additional questions regarding the autogenous healing of cement-mortar lined Ductile iron pipe, feel free to contact your local McWane Ductile Sales Representative. Our team members strive to provide education and assistance to water professionals throughout the waterworks industry.

References

- McWane Ductile YouTube - https://www.youtube.com/channel/UCIOR4Yg0_Ct-VKktFypRDfA

- McWane FAQ’s - https://www.mcwaneductile.com/learning-center/frequently-asked-questions/

- AWWA Research Foundation - “Autogenous Healing of Concrete in the Drinking Water Industry” – Prepared by: Jeffry Parks, Marc Edwards, Peter Vikesland, Matthew Fiss, & Abhijeet Dudi – Virgina Polytechnic Institute and State University, 418 Durham Hall, Blacksburg, VA 24061

- Ductile Iron Pipe Research Association – “Cement-Mortar Linings for Ductile Iron Pipe” – Prepared by: Richard W. Bonds, P.E.

- McWane Inc. Multimedia Library