Have you ever considered how high temperatures impact your choice of piping material for a water system? It might not be something that comes to mind immediately, but it’s an important factor. Water treatment specialists pay close attention to water temperatures because they influence how the water reacts to treatment chemicals. Additionally, water and ground temperatures can significantly affect the performance of certain piping materials, particularly polyvinyl chloride (PVC).

Let’s explore how temperature can create challenges for your water system and why selecting the best piping material—such as Ductile iron pipe (DI pipe)—is essential to ensure long-term reliability, sustainability, and efficiency.

How does water temperature affect water treatment?

Water utilities employ water treatment specialists who are trained to manage the water supply to ensure it meets quality standards for public consumption. These specialists must consider how water temperature impacts the chemical, biological, and physical properties of the water.

Water temperature influences chemical reactions, biological activity, and oxygen levels, all critical factors in water treatment. Federal Law established the Safe Water Drinking Act in 1974 as the primary law to address these variations, ensuring that water is treated and delivered safely and effectively, regardless of temperature fluctuations. This careful consideration helps maintain the safety and quality of drinking water for the public.

A Brief Look at PVC Pipe AWWA Standard History

In 2007, the American Water Works Association’s (AWWA) C900 standard underwent significant changes, reducing the safety factor from 2.5 to 2.0 and eliminating the surge allowance. This revision aligned C900 with C905, adopting a less conservative design philosophy that no longer accounts for surge pressures in PVC pressure calculations.

By 2016, AWWA had merged the C905 standard into C900, creating a unified standard for PVC pipes ranging from 4 to 60 inches. This update also introduced new Dimension Ratios (DRs) and highlighted limitations unique to PVC pipe.

The updated C900 standard also provides guidelines for managing surge pressures, categorizing them as occasional or recurring surges. Furthermore, the standard includes specific adjustments for pressure capacity based on pipe temperature. Nominal pressure ratings are defined at 73.4°F; higher temperatures reduce PVC's pressure capacity, requiring modifications to ensure safe and reliable operation.

Temperature Effects on PVC Pipe Stiffness:

Temperature fluctuations can significantly impact the stiffness and flexibility of polyvinyl chloride pipes. The risks of not considering this temperature-dependent behavior during the design and installation of systems include structural integrity issues under varying conditions. At higher temperatures, PVC becomes soft and fragile, making it susceptible to deformation and potential collapse under the weight of the trench. Fluctuations in these mechanical properties may decrease the pipe's performance and lifecycle.

The thermoplastic nature of polyvinyl chloride pipe causes physical properties to change with temperature, necessitating adjustments to pressure ratings at elevated operating temperatures. AWWA C900 provides de-rating factors to guide these adjustments. For instance, the pressure capacity is reduced to 88 percent at 80°F and further to 62 percent at 100°F. The table below demonstrates the importance of considering temperature adjustments in system design to prevent failure and maintain reliability for DR18 and DR14 pipe.

PVC Pipe Temperature Coefficients

| Pipe Temperature (F) | Pressure Rating Reduction | DR 18 (235 psi) (F) | DR 14 (305 psi) (F) |

| 73.4 | 100 percent | 235 | 305 |

| 80 | 88 percent | 207 | 268 |

| 90 | 75 percent | 176 | 229 |

| 100 | 62 percent | 146 | 189 |

| 110 | 50 percent | 118 | 153 |

| 120 | 40 percent | 94 | 122 |

| 130 | 30 percent | 71 | 92 |

| 140 | 22 percent | 52 | 67 |

Atmospheric temperature affects the ground temperature

Pipe temperatures are closely influenced by the surrounding soil and water temperatures, which, in turn, are affected by surface temperatures. Studies indicate that soil temperature decreases by approximately 6.6°F for every foot of depth beneath unshaded asphalt. This relationship is critical because pipe temperature aligns closely with the surrounding soil conditions.

The depth of water systems varies by region across the United States and plays a significant role in determining pipe temperature. For example, with a surface temperature of 110°F, the pipe temperature at a depth of three feet would be around 90°F, reflecting a roughly 20°F decrease. Hence, the pressure rating for an 8-inch polyvinyl chloride DR 18 pipe would decrease by 25 percent from 235 psi to 176 psi. It is important to note that waterlines are typically hydrostatically tested at 150 psi or above.

While seasonal changes cause significant variations in atmospheric temperatures, soil temperatures fluctuate less dramatically but still correlate closely. This stabilization effect helps regulate pipe and water temperatures in distribution systems, ensuring more consistent operating conditions.

Why Ductile Iron Pipe is ideal for high-temperature environments

Ductile iron pipe provides several advantages for managing high temperatures, making them the ideal choice for water systems in hotter climates. Unlike other materials, Ductile iron is not affected by elevated temperatures in the water or atmosphere. While it does experience thermal expansion, the effects are minimal, and the pipe joints are designed to accommodate expansion and contraction seamlessly. Polyvinyl chloride is damaged by ultraviolet rays (UV), whereas UV rays do not damage DI pipe. The ANSI/AWWA C900 Standard recommends covering polyvinyl chloride pipe when exposed to UV rays during storage.

The durability and strength of Ductile iron pipes make them highly resistant to both external and internal pressures, ensuring reliable performance under demanding conditions. Additionally, DI pipe boasts a long lifespan, offering exceptional value and making it a wiser long-term investment for water systems.

This discussion has centered on the effects of atmospheric temperature on water pipes. Speaking of heat, studies have also been conducted on the impact of wildfires on water pipes. McWane Ductile provides excellent sources for additional information on this topic, including these two #IronStrong blogs:

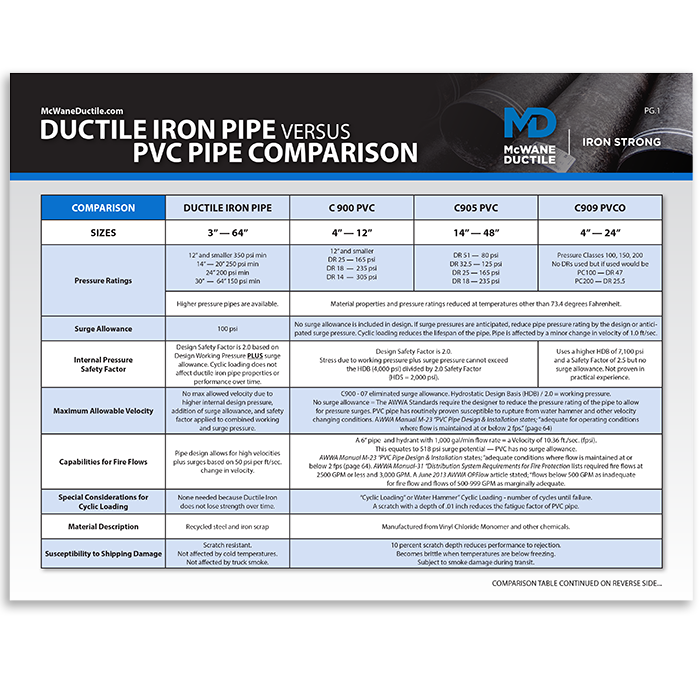

What is the difference and advantage of Ductile iron over PVC pipe? Many things! Use this handy comparison sheet to ensure you specify the safest, durable, and longest-lasting pipe for your next project.

Conclusion

By understanding these temperature-related challenges, utilities can make informed decisions about material selection to ensure their systems remain reliable and efficient under diverse conditions. Designing or upgrading a water system in areas with high temperatures requires selecting piping materials capable of withstanding environmental stresses.

Ductile iron pipes are an excellent choice for high-temperature applications, offering superior strength, heat resistance, and durability compared to alternatives like PVC. Choosing Ductile iron ensures a reliable and efficient water system, even in extreme conditions, while also reducing maintenance costs and extending the system's lifespan.

Ultimately, collaborating with an engineer to evaluate local environmental and water conditions and material options like Ductile iron is essential for making the best decision to meet your system's specific needs.

References:

- WaterWorld, “Arizona: PVC Pipe’s Proving Ground.” Accessed December 22, 2024. https://www.waterworld.com/drinking-water-treatment/distribution/article/16200954/arizona-pvc-pipes-proving-ground.

- Polyfab, “How Temperature Affects PVC Pipe.” Accessed December 21, 2024. https://www.polyfabonline.com/pvc-pipe-temperature-ratings/.

- AQUACHEM, “The Importance of Water Temperature in Water Systems.” Accessed December 21, 2024. https://www.aquachem.ie/waterblog/watertemperature/

- DIPRA: Caution: PVC Pipe may not Handle the Pressure, Sept. 1, 2017. https://dipra.org/news/news-and-commentary/caution-pvc-pipe-may-not-handle-the-pressure

- ANSI/AWWA C900-22, Polyvinyl Chloride (PVC) Pressure Pipe and Fabricated Fittings, 4-in Through 60-in (100 mm Through 1,500 mm), Page 14, Table 3.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is equipped with the expertise to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.