One question we often receive in the field is, "Can you use Ductile iron pipe (DI pipe) when running hot water or steam through pipe?" The answer to that question is YES, but there are several factors you must consider. For this Iron Strong Blog, we are going to look at these factors to help determine what products are needed for each application.

What Is Steam?

First things first, what is steam? Merriam Webster's definition is “The vapor into which water is changed when heated to the boiling point.” The temperature that transformation occurs is 212 degrees Fahrenheit. So, when you are designing a pipeline to accommodate the potential of 212 degrees or above, there are three things you need to consider when using DI pipe.

Three Things to Consider:

- What interior lining do you need?

- What type of gasket do you need?

- Do you need corrosion protection?

What Interior Linings Work With Steam Applications?

The typical interior lining for DI pipe as it pertains to drinking water is a cement-mortar lining with a seal coat. As per the latest revision of the ANSI/AWWA C104/A21.4 standard, some water systems may choose to use cement lining with no seal coat. For more information on interior linings, please check out some of our previous blog postings below.

- Seal Coat process for Ductile Iron Pipe

- What Is Ductile Iron Pipe Seal Coat?

- What Pipe Linings Are Best for Sewer Applications?

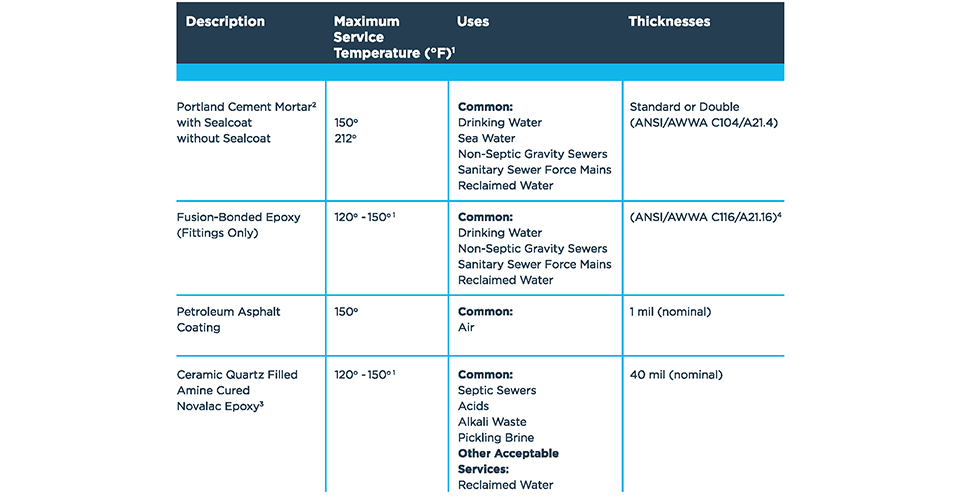

For this example, we are going to say we are designing a Ductile iron hot water/steam line that could have maximum temperatures up to 225 degrees Fahrenheit. Please reference the chart below.

As you can see, the maximum service temperature for cement mortar with seal coat is 150 degrees Fahrenheit. If you were to use cement lining without seal coat the maximum service temperature would be 212 degrees Fahrenheit. In our example, the maximum temperature we must account for is 225 degrees Fahrenheit, so in that scenario, you would have to supply the DI pipe with "no interior lining" or " bare inside." One thing to keep in mind when ordering bare inside pipe is that it is not a standard product, so there will be a longer lead time. For more information on DI pipe lead times, check out the video below:

Just remember, for our example, we are using 225 degrees Fahrenheit as the maximum service temperature. If you are looking at a maximum service temperature of 212 degrees Fahrenheit or below, you can use cement lining with no seal coat.

What Gasket Materials Can I Use With Steam?

The standard gasket used for DI pipe is a Styrene-Butadiene Rubber (SBR) gasket. The SBR gasket is shipped with every joint of DI pipe unless specialty gaskets are ordered. There are four additional specialty gasket elastomers available for DI pipe:

- EPDM (Ethylene Propylene Diene Monomer) gasket

- Nitrile (Acrylonitrile Butadiene) gasket

- Neoprene (Polychloroprene) gasket

- Viton® (Fluorocarbon) gasket

For more information on specialty gaskets please check out the video blog below:

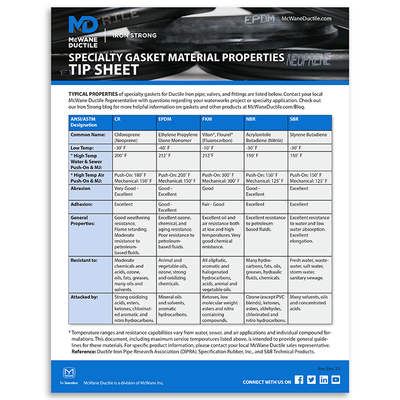

For the gaskets, we will use the same example criteria as we did for interior linings; that is, we are designing a Ductile iron water line that has a maximum service temperature of 225 degrees Fahrenheit. Please reference the chart found in our handy downloadable gasket materials tip sheet:

Certain gaskets are built for certain pipeline scenarios. This handy tip sheet, listing the properties of specialty gaskets, will help specify the right gasket for the job.

As you can see, the only option for the maximum service temperature of 225 degrees Fahrenheit is the Viton (Fluorocarbon) gasket. If you are designing a line that has a maximum service temperature of 212 degrees or below, you could look at using an EPDM gasket. As a reminder, be sure to properly care for your gaskets. Check out the handy tip sheet below on proper gasket storage.

Take care of critical components of your pipeline system! Avoid the harmful effects of improper gasket storage with our free and handy tip sheet.

Will Corrosion Protection Be Needed?

The last thing to consider when designing a hot water/steam line is, “Will I need corrosion protection?” The answer to this will first depend on the installation method. A lot of hot water/steam lines are above ground installations that typically do not require corrosion protection.

If the pipe is to be installed in a buried application, though, some thought will need to be given to what corrosion protection method can or should be used. The most common and cost effective means to protect buried Ductile iron pipe from corrosion is to encase the pipe in polyethylene per ANSI/AWWA C105/A21.5, or V-Bio® Enhanced Polyethylene Encasement.

However, for a project with a maximum operating temperature of 225 degrees Fahrenheit, you would not be able to use V-Bio or any other form of polyethylene encasement. The maximum service temperature for V-Bio is 180 degrees Fahrenheit. For a other types of encasement, such as a high-density cross-laminated polyethylene, the maximum service temperature is 200 degrees.

So, for our example, you could have to install a bonded coating for DI pipe in conjunction with a cathodic protection system. The system chosen would be a site-specific application and may require the services of a corrosion professional for design. For more information on what corrosion control system works best for your installation, see this helpful blog.

We've also produced a helpful video below by Regional Sales Engineer John Johnson that explains the DIPRA-Corrpro Design Decision Model® and how it's used to determine what type of corrosion protection, if any, your pipeline will need.

Need Assistance with Your Waterworks Project?

In closing, if you have any questions about this topic or any topic, please contact your local McWane Ductile representative. We have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to installation, we take great pride in providing education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings