The water industry in the United States has experienced many challenges throughout the years. The good news is that these challenges have been met head-on by experienced, dedicated professionals who continue to provide their customers with clean, safe drinking water even though the bar of excellence continues to rise. One measure depicting the priority of these challenges is the State of the Water Industry Survey, conducted annually by the American Water Works Association. “AWWA’s State of the Water Industry (SOTWI) Survey is designed to identify water sector challenges and investigate possible underlying causes and drivers. In November 2022, when the survey closed, 4,123 water professionals had shared their opinions by responding to the survey—our highest number of responses yet!”(1)

OPTIMISM

Even though the challenges identified by industry participants were substantial, the 2023 optimism score was 5 out of 7. Noting this optimism was David LaFrance, AWWA CEO. “It’s clear there are significant hurdles in front of us—from infrastructure replacement to resource challenges to new contaminants to cybersecurity concerns—but water professionals never blink; they simply find ways to solve the problems in front of them and keep providing the world’s most vital resource to their communities.” (2)

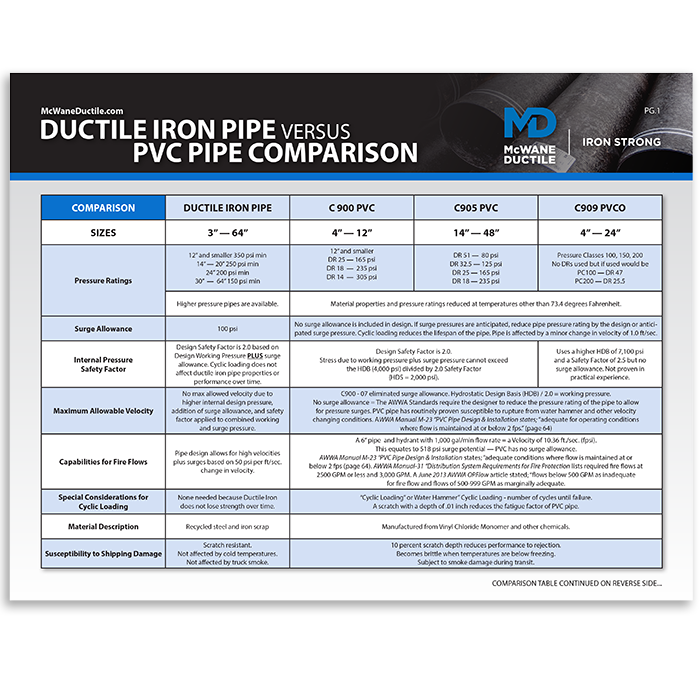

What are the differences and advantages of Ductile iron over PVC pipe? Many things! Use this handy comparison sheet to ensure you specify the safest, durable, and longest-lasting pipe for your next project.

DOWNLOAD NOW

WHAT ARE WATER SYSTEM CHALLENGES IDENTIFIED IN AWWA’S SOTWI SURVEY FOR 2023 THAT DIRECTLY RELATE TO A UTILITY’S UNDERGROUND INFRASTRUCTURE?

Approximately 80% of a water utility’s investment is in its underground infrastructure. The proper selection of pipeline materials can have a significant effect on several financial components of a water system. Hydraulic efficiencies can save virtually millions of dollars over the life span of a pipeline on a utility’s electric bill. Construction costs can be dramatically reduced by evaluating required backfill conditions and eliminating various appurtenances. Substantial future capital investment can be deferred when evaluating life cycle cost analysis, and carbon footprints must also be considered to satisfy the growing environmental concerns of those the utility serves. Thus, the proper selection of pipeline materials is key to addressing some of these industry challenges in the future, as noted in the survey.

Rehabilitation & Replacement of Aging Water Infrastructure:

This was the No. 1 challenge identified in the 2023 SOTWI Survey. When replacing this underground infrastructure, strategic analysis of materials used should be applied to guarantee that the future aging of this infrastructure extends well into and beyond future generations. The Buried No Longer Report (5) published by AWWA sets forth the estimated service life for various pipeline materials for different diameters in different country regions. The estimated service life for Ductile iron pipe is shown to be 105 years. However, in many cases, other materials show significantly less value; some are only listed with half the estimated service life of Ductile iron pipe.

Financing for Capital Improvements:

This particular challenge is listed as No. 3. When utilities seek capital funding for new treatment plants, booster stations, or even operations/office facilities, much planning is performed to ensure these structures and appurtenances are resilient and sustainable, obviously an expectation of investors and customers. The same strategic thought should be applied in selecting pipe material, not succumbing to the least cost material available but selecting materials that give the greater value for the long term, as highlighted in AWWA’s Buried No Longer Report. This sustainability aspect also aligns with the key driver of sustainability in AWWA’s Water 2050 Initiative.

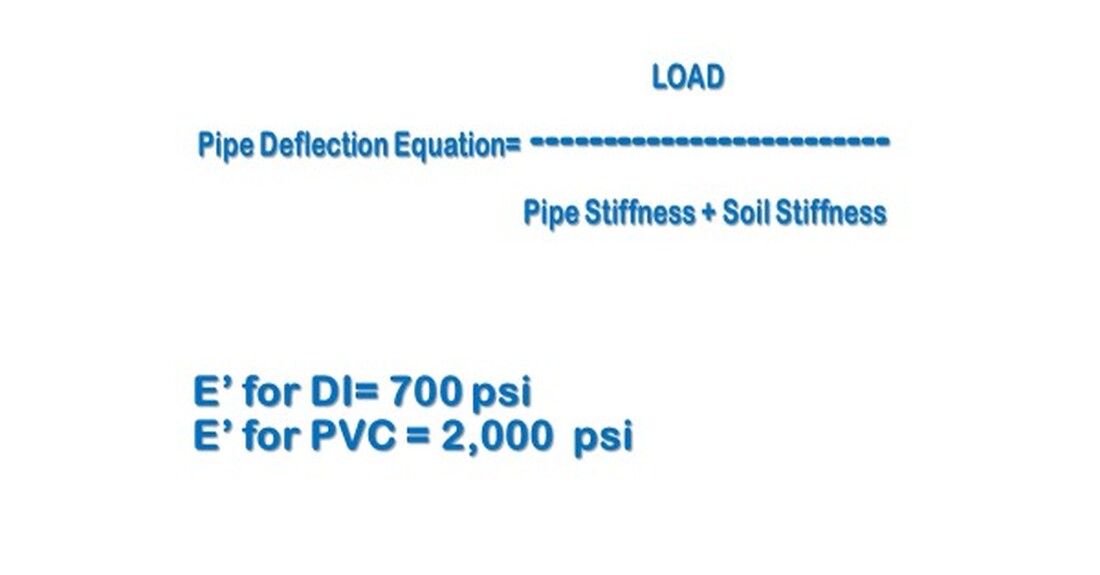

Additionally, lower construction costs to install new pipelines can directly relate to pipeline material selection. In the equation noted below, a pipe’s deflection within a trench after installation is determined by the pipe's stiffness and the soil surrounding it. Thus, to ensure the pipeline’s deflection is within acceptable guidelines so as not to cause failure, a soil modulus (E’) must be respectively constructed. The higher the (E’) value needed, the more expensive the trench to prepare for receiving the pipe.

Water Conservation/Efficiency, Drought or Periodic Water Shortages, and Water Loss Control:

These three challenges noted in the top 20 list come in at No. 11, 14, and 17, respectively. Many water systems throughout the country have struggled with some, if not all, of these issues for many years. Whether it be an inadequate supply source, weather conditions, system dynamics such as high pressures, or insufficient treatment/pumping capabilities, to mention a few, "every drop counts" has been more meaningful to some than others. However, even water utilities with abundant source water and reserve capacities have seen the expectations of stakeholders and society in general when it comes to inordinate water waste in any fashion. Thus, the issue of water loss control becomes a factor in all of these areas. When pipelines are buried underground, out of sight, and often out of mind, certain stress intensifiers can come into play.

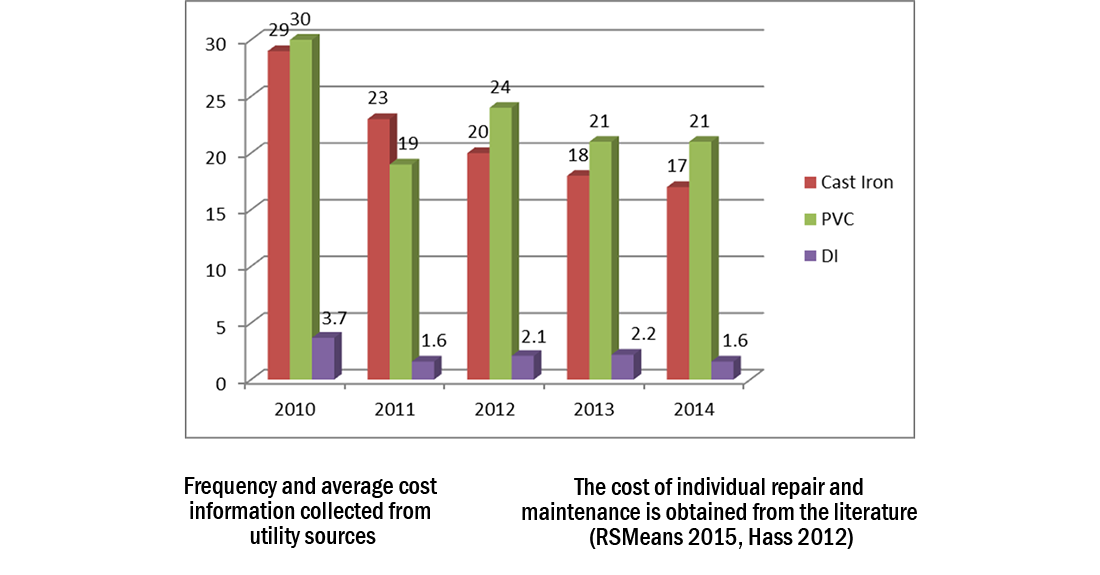

Certain pipeline materials are much more sustainable underground when these intensifiers begin to react with the pipe itself. Ductile iron pipe is virtually unaffected by such intensifiers, whereas other materials, such as plastics, can yield, causing leaks. The chart below, which shows data from a University of Michigan research study entitled, A Framework to Evaluate Lifecycle Costs and Environmental Impacts of Water Pipelines, (6) highlights the frequency and cost of main repairs specifically in Ductile iron, cast iron, and PVC pipes.

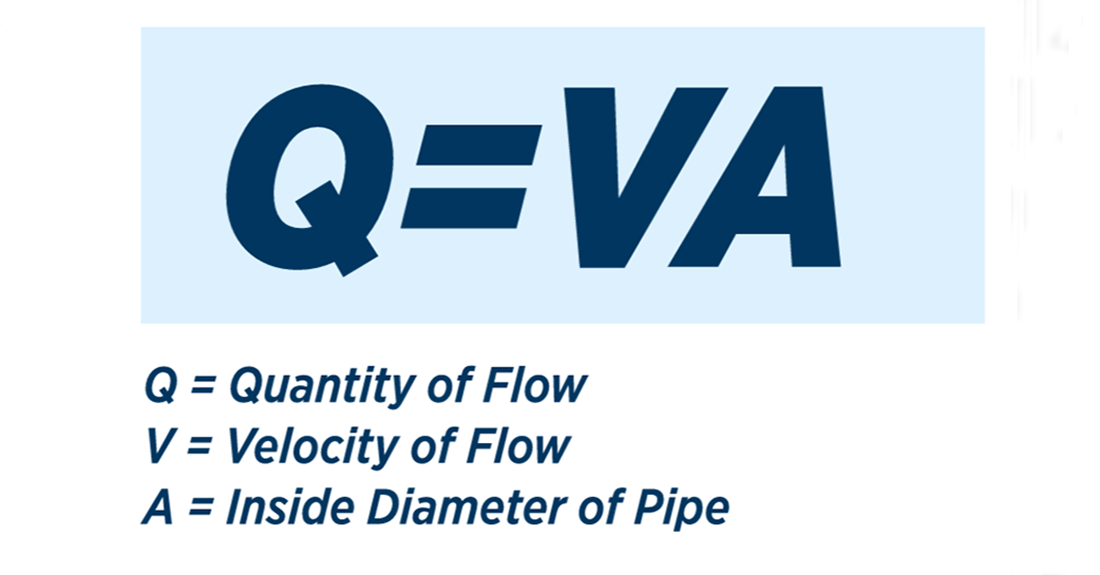

Additionally, certain utilities have conducted their own research, finding the use of Ductile iron pipe has significantly curtailed unaccounted-for water in their systems. (7) Energy Use/Efficiency and Cost: This item is listed as No. 18 in the top 20 list. Progressively throughout the years, energy use and efficiency, which ultimately translates to cost to the utility, has been an increasingly high priority. Assuring pumps and motors operate within efficient guidelines has gained much attention and focus. However, should the terms energy efficiency and pipeline material selection be used in the same sentence? ABSOLUTELY, and it can be clarified by the equation below:

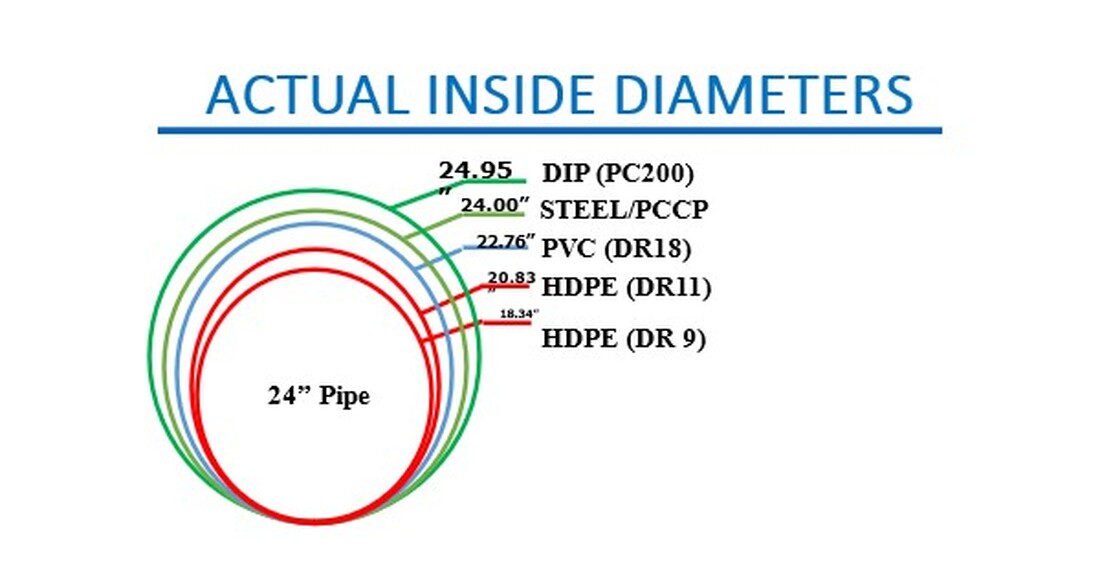

When a certain flow requirement (Q) is needed at a certain location in a water system for fire flows, customer usage, or any reason, then the inside diameter of the pipeline (A) carrying that flow directly relates to the velocity (V) of flow in the pipeline. A higher velocity is required to accommodate the needed flow if a pipeline has a smaller inside diameter. This higher velocity requirement almost always involves the application of additional pumping, which then translates into direct energy cost to the utility. A schematic is shown below, depicting the respective inside diameters of differing water pipeline materials. The choice of hydraulically efficient pipeline material like Ductile iron pipe inherently assists the utility in addressing the energy cost challenge noted as a top 20 concern.

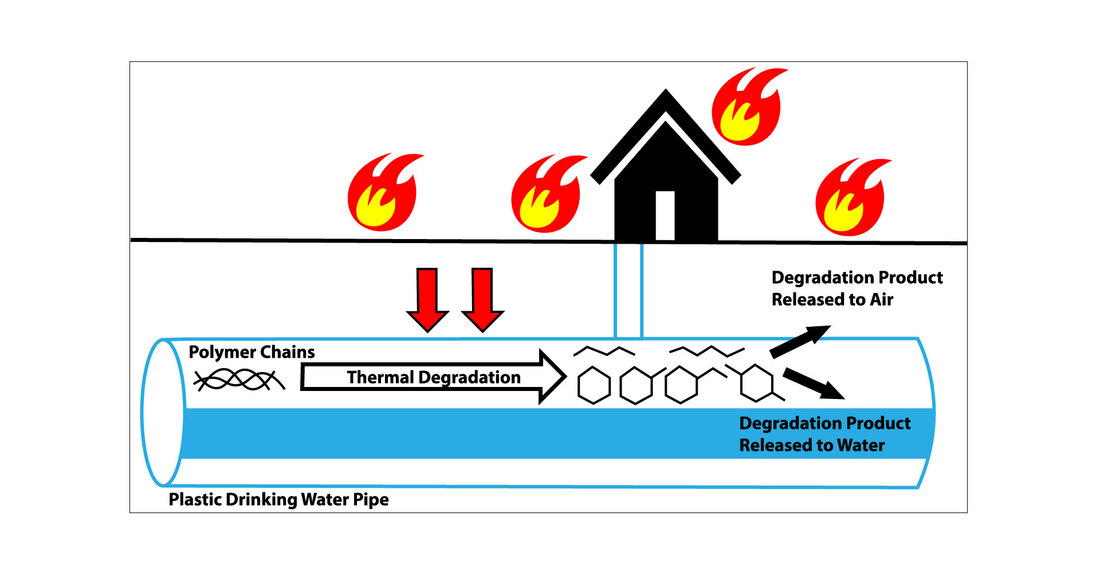

LARGE-SCALE PHENOMENA

SOTWI participants were asked to rank a list relating to issues of large-scale phenomena. Two notable issues identified were energy costs and extreme weather events. Having previously discussed the issue of energy costs, pipeline material selection can also be a major component in a water system’s integrity when it comes to extreme weather events. Beyond the obvious resilience, strength, and sustainability of Ductile iron pipe during such events as flooding caused by numerous weather scenarios, it has been found, as seen below, that certain pipeline materials DO NOT continue their functionality as opposed to Ductile iron pipe in wildfire conditions.

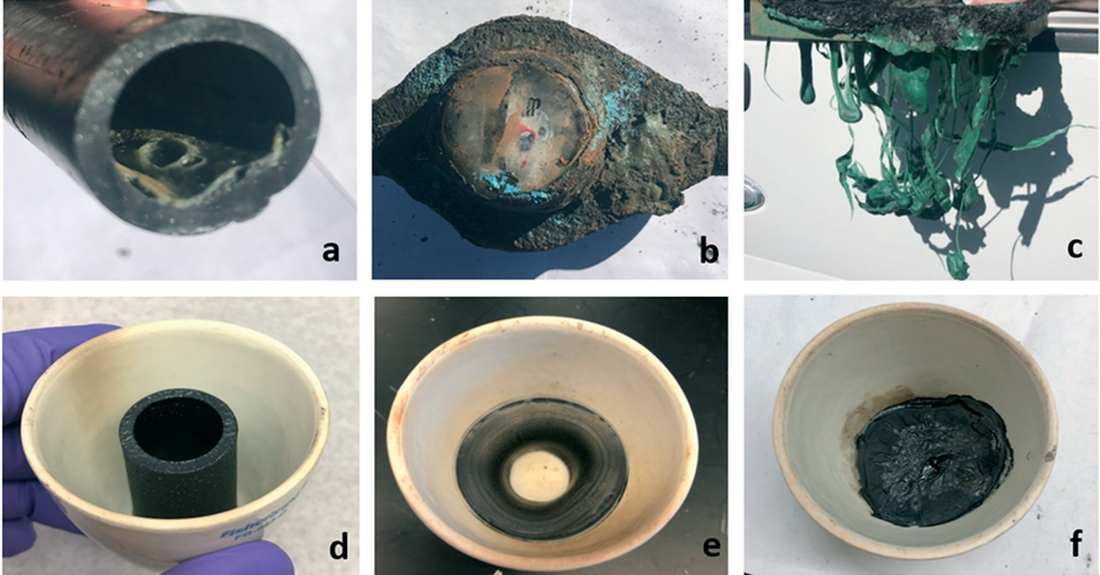

The images below show fire-damaged water system components, including (a) a HDPE plastic pipe, (b) a water meter, and (c) a water meter cover following the Camp Fire. Thermally degraded pipe samples in laboratory experiments include (d) PEX-c pipe degraded at 300 C, (e) HDPE pipe degraded at 300 C, and (f) HDPE pipe degraded at 400 C.

SUMMARY

The water utility industry, I’m sure, will persevere as always in addressing those industry challenges outlined in AWWA’s 2023 SOTWI. One prominent component that is highlighted repeatedly when meeting many of these challenges is SUSTAINABILITY. The proper, strategic selection of pipeline materials in the utility’s underground infrastructure should reflect value for their customers well into the future, not only reflecting the short-term cost decisions of today.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

REFERENCES

1–4. American Water Works Association; State of the Water Industry Survey, 2023.

5. American Water Works Association; Buried No Longer, 2012.

6. University of Michigan; “A Framework to Evaluate Lifecycle Costs and Environmental Impacts of Water Pipelines”, 2016.

7. Mundy, Roy. "Why Use Ductile Iron Pipe? An Interview with Bill Dunnill, GM Consolidated Utility District." Iron Strong Blog, May 3, 2019. Accessed December 10, 2023. McWaneDuctile.com/blog/.