There are occasions during field installation of Ductile iron pipe (DI pipe) when a Chamfered edge or a beveled edge may be required. There is typically a sharp edge on any metal pipe after field cutting. This edge is a safety hazard that requires removal. The sharp edge may also damage a gasket during installation, which is an additional reason to remove the sharp edge. Read on to see the differences and why it is essential to have the proper edge on a field-cut DI pipe.

Ray from Rochester Asks… I thought a chamfer and a bevel on a pipe were the same things. Is that right?

For a refresher on cutting DI pipe in the field, check out this Iron Strong Blog with video and handy tip sheet by Jason Barnes.

What Is a Chamfer?

To Chamfer a pipe or metal surface is simply to remove the sharp edge, producing a symmetrical sloping edge. This can be achieved by using a metal file or orbital grinder.

What Is a Bevel?

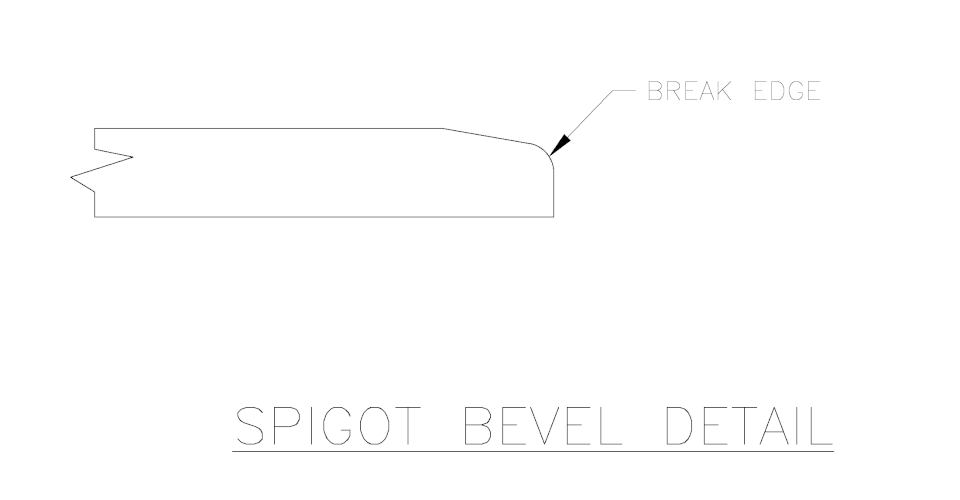

Beveling a pipe requires removing the edge and producing a slope on the end of the pipe. The outside of the cut end should be beveled about ¼-inch at an angle of approximately 15 to 30 degrees. This can be easily done with a portable grinder. The operation removes any sharp, rough edges which otherwise might damage the gasket.

How Do I Chamfer or Bevel a Pipe?

Jerry Regula “JR” provides a short video explaining how to Chamfer or Bevel a field cut pipe below:

When Do I Chamfer Versus Bevel?

The decision to Chamfer or Bevel depends on the connection to be made. Chamfering is adequate when the connection will be an MJ (Mechanical Joint) such as an MJ Fitting or Valve. A beveled end is required for a Tyton® installation.

Pro Tip: A beveled end may be inserted into an MJ connection.

Example: Inserting a Tyton® pipe with a factory or field applied beveled end into an MJ Fitting or Valve.

How Does an MJ Connection Differ from a Tyton Connection?

MJ and Tyton connections are different concerning the compression of the gasket. The MJ gasket is compressed by the gland when the bolts are tightened to the proper torque. The Tyton gasket is compressed when the spigot end is inserted into the bell. The bevel, therefore, helps the operator to "center" the spigot with the gasket.

Where Can I Find a Specification on Beveling?

Beveling is outlined in the ANSI/AWWA C600 Installation of Ductile Iron Mains and Their Appurtenances Standard and the AWWA M41 Ductile-Iron Pipe and Fittings manual.

ANSI/AWWA C600 Section 4.3 Installing Ductile-Iron Mains: "4.3.4.5.3: Cut ends and rough edges shall be ground smooth, and, for push-on joint connections, the cut end shall be beveled by methods recommended by the manufacturer."

Do you have a question for the Ditch Doctor? We’re here to answer! Click the button below to submit your inquiry about constructing Ductile iron pipelines.

Need Assistance with Your Waterworks Project?

If you have any questions or need additional information, please feel free to contact your local McWane Ductile Representative. We have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to installation, we take great pride in providing education and assistance to water professionals throughout the water and wastewater industry.