In the realm of Ductile iron pipe (DI pipe) joints, standard SBR (Styrene Butadiene) gaskets are the traditional watertight sealing solution. However, did you know these gaskets are not intended for all applications? When dealing with unique jobs, selecting the proper gasket material catering to specific operational demands is essential.

There are specialized gaskets, distinct in composition and functionality, that transcend the conventional capabilities of SBR gaskets. Each gasket described below is made for specific purposes based on factors like soil conditions, service temperature, or powerful industrial forces. These gaskets utilize modern elastomers to withstand the demands of any given project. In this #IronStrong Blog, we will closely examine each gasket available for your pipeline project.

How Do You Select the Right Specialty Gasket for the Job?

First, be sure to use specialty gaskets provided by the pipe manufacturer. McWane Ductile only provides gaskets that are manufactured to the ANSI/AWWA C111-12 Rubber-Gasket Joints for Ductile-Iron Pressure Pipe and Fittings Standard, are NSF61, and NSF372 compliant, and approved as safe for use with potable or wastewater systems.

The key priority is using the right gasket suited for your specific application. And remember, the vast majority of water and wastewater projects will install standard SBR gaskets.

Click the play button in the image below to view an informative video on specialty gaskets.

SBR (STYRENE-BUTADIENE) GASKETS

While Styrene Butadiene (SBR) gaskets are not considered a “specialty” gasket, they are the most common synthetic gasket material in the Ductile iron pipe industry. SBR gaskets are a copolymer, essentially two or more varieties of natural rubber combined to create a more durable blend of rubber. Every piece of DI pipe is shipped standard with an SBR gasket. High tensile and impact strength make it resistant to tearing and cracks. It is intended for use in average temperatures, up to 150 degrees Fahrenheit.

Applications where SBR gaskets are commonly used are:

- Drinking Water

- Salt Water

- Stormwater

- Raw Water

- Sanitary Sewage

EPDM (ETHYLENE PROPYLENE DIENE MONOMER) GASKETS

Our first specialty gasket is made from Ethylene Propylene Diene Monomer or EPDM. This synthetic rubber is durable, weather-resistant, and flexible at temperatures below freezing. It is also an excellent choice for high-temperature applications, as it has one of the highest service temperatures of the five major specialty gaskets at up to 212 degrees Fahrenheit for water and sewer applications. EPDM pipe gaskets have low gas and vapor permeability and resist various chemicals, including acids and solvents, which are listed below.

EPDM gaskets are commonly used with Ductile Iron pipe when there is the presence of:

- Animal and Vegetable Oils

- Ozone (a chemical reaction between nitrogen oxides and volatile organic compounds)

- Dilute Acids

- Alkalis

- Ketones (MEK Acetone)

- Strong and oxidizing chemicals

- Alcohol

They can also be used with other acceptable services, including:

- Drinking-Water

- Sea Water

- Sanitary Sewage

- Reclaimed Water

- Raw Water

- Storm Water

NITRILE (NBR) (ACRYLONITRILE BUTADIENE) GASKETS

Our next specialty rubber gasket is called Nitrile or NBR. Nitrile gaskets have a maximum service temperature of 150 degrees Fahrenheit for water and sewer applications. While Nitrile is resistant to deterioration, it is not impervious to low molecular weight petroleum products, and FKM Gaskets (described below) should be considered as an alternative in some cases.1

Nitrile gaskets are commonly used with Ductile iron pipe when there is the presence of:

- Hydrocarbons (a chief component of petroleum and natural gas)

- Refined Petroleum Oils and Fluids

- Fats

- Greases

- Hydraulic fluids

- Chemicals

Other acceptable services include:

- Drinking Water

- Sanitary Sewage

- Reclaimed Water

- Raw Water

- Storm Water

NEOPRENE (CR) (POLYCHLOROPRENE) GASKETS

Next up is the Neoprene gasket. It is superior at handling greasy waste and has flame-resistant qualities. Neoprene gaskets have a maximum service temperature of 200 degrees Fahrenheit for water and sewer applications.

Neoprene gaskets are commonly used with Ductile Iron pipe when there is the presence of:

- Moderate chemicals and acids

- Ozone

- Oils

- Fats

- Greases

- Many oils and solvents

Other acceptable services include:

- Fresh Water

- Sea Water

- Sanitary Sewage

- Reclaimed Water

- Raw Water

- Storm Water

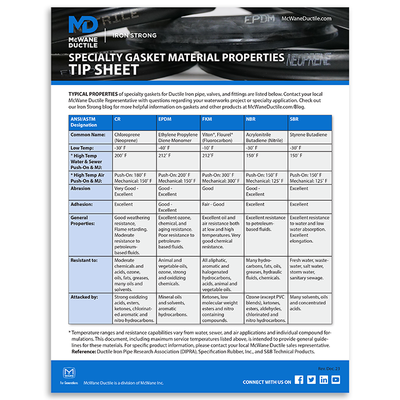

Certain gaskets are built for certain pipeline scenarios. This handy tip sheet, listing the properties of specialty gaskets, will help specify the right gasket for the job.

VITON, FLUOREL (FKM) (FLUOROCARBON) GASKETS

Lastly, we have the Viton gasket, aka FKM. Viton gaskets are another exceptional choice for high-heat situations, with a maximum service temperature of 212 degrees Fahrenheit for water and sewer applications. Due to its excellent permeation resistance, FKM is typically specified for potable water lines in areas saturated with low molecular weight petroleum products.1 With superior chemical resistance and high-temperature stability, the Viton gasket has the best level of performance out of all the specialty gaskets for Ductile Iron pipe.

Viton gaskets are commonly used with Ductile Iron pipe when there is the presence of:

- Aliphatic hydrocarbons (example: methane),

- Aromatic hydrocarbons (examples: toluene and benzene), and

- Halogenated hydrocarbons (examples: Fluorine, chlorine, or bromine)

- Petroleum products

- Most chemicals and solvents

- Acids

- Animal and vegetable oils

Other acceptable services include:

- Drinking Water

- Reclaimed Water

- Raw Water

- Storm Water

How Do You Identify Each Specialty Gasket?

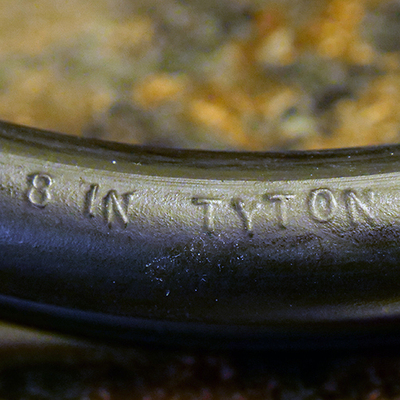

Sometimes, it can be challenging to differentiate specialty gaskets at first glance, so you want to look closely. Typically, the variety of elastomers will be imprinted on the gasket using its common industry name (such as shown above).

Additionally, push-on joint gaskets all have the size, type, and country of origin molded into the side of the gasket in small letters. From this, you should be able to find what type and size of the gasket you are installing (such as shown below).

Caring for Your Gaskets

Now, once your gaskets have been delivered to the job site, be sure to take proper care of your investment. Several factors can harm the overall performance of your gaskets. Such negative factors include, but are not limited to:

- Direct sunlight

- Temperature

- Weather

- Dirt

- Debris

When it comes to identifying, caring for, and installing your gaskets, be sure to check out these Iron Strong blogs by my colleagues:

Take care of critical components of your pipeline system! Avoid the harmful effects of improper gasket storage with our free and handy tip sheet.

The expected lifecycle of Ductile iron pipe is over 100 years. Now that you can identify the correct specialty gasket for any pipeline application, you can be confident that your project will be Iron Strong in the long run. Although this blog is intended to provide general guidelines regarding the usage of specialty gasket elastomers, for specific information, please get in touch with one of our Regional or Product Engineers for assistance.

Special thanks to Specification Rubber Products, Inc. for providing the gaskets we demonstrated in this vlog.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

- More articles and videos from our Iron Strong Blog

- Training Opportunities with McWane Ductile

- The McWane Pocket Engineer

- Engage with us on LinkedIn

- Subscribe to our YouTube Channel

- Follow us on Facebook

- Follow us on Twitter

References:

- Specification Rubber Products, Inc., "Submittal and Spec Sheets," Accessed December 4, 2023. https://specrubber.com/submittal-spec-sheets/

- Ductile Iron Pipe Research Association, "Gasket Materials Used for Ductile Iron Pipe in Water and Sewer Service," Accessed December 4, 2023. https://dipra.org/docs/gasket-materials-used-for-ductile-iron-pipe-in-water-and-sewage-service

- S&B Technical, "Specialty Elastomers Gaskets," Accessed December 5, 2023. https://www.sbtechprod.com/ductile-iron-pipe-and-fittings/