It is very common to get certain questions from our customers regarding the interchangeability of push-on or compression type gaskets that are typically supplied with Ductile iron pipe. These questions are usually easy to answer in a very definitive manner, but there are some exceptions. In this edition of Iron Strong, we will address the three most common questions about gaskets and why this can sometimes be confusing to our customers.

Does it matter which manufacturers gasket is used when installing pipe?

Perhaps a better way to address this question would be ask what brand or manufacturer of pipe are you using? As this will determine the joint type that has been supplied.

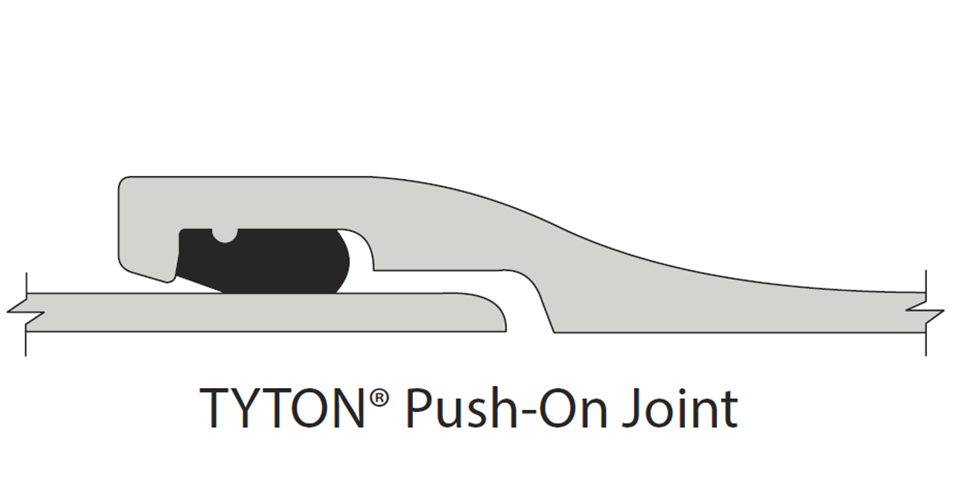

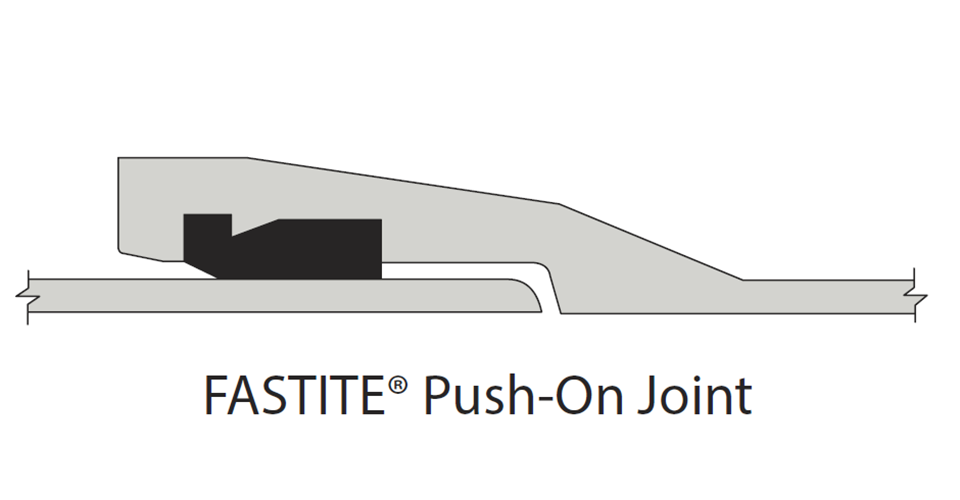

There are two domestically manufactured push-on joint types; 1.) The Tyton Joint® as manufactured by McWane Ductile and U.S. Pipe and 2.) the Fastite® joint as manufactured by American Cast Iron Pipe Company (American). Therefore, push-on pipe that is manufactured by McWane Ductile or U.S. Pipe are interchangeable, but neither is interchangeable with pipe manufactured by American.

To understand the difference between the two joints, you must first understand how the joints and gaskets work together to give you a water tight seal. Notice I said “WATER TIGHT.” Ductile Iron pipe joints are not designed to be air tight. They may be able to pass a limited air test, but the joints are only designed to be water tight. That’s a topic for another day.

With each gasket, no matter who the manufacturer is, there is a heel which sits in the groove of the pipe joint and a bulb, which when compressed against the outside diameter (OD) of the spigot end, forms a water tight seal.

Have you ever noticed that the heel and bulb do not feel like they are made from the same rubber? That’s because the two parts are produced at different levels of hardness, as measured by their durometer. The elastomer is the same, but they are a different hardness. This is where the term “dual durometer” comes from.

The harder rubber of the heel makes it more rigid and helps hold the gasket in place as the joint is being assembled. The bulb, made of a softer rubber, will compress easier during joint assembly than if it were made of a harder rubber.

When inserted into the bell, the heel and bulb are installed over a retainer bead that is cast into the bell section of the pipe. The retainer bead allows the heel to “hang on” during spigot insertion while keeping the gasket properly in place. No matter the brand, all compression joint pipes are cast with this retainer bead in the bell.

The Tyton Joint® uses a semi-circle retainer bead, while the Fastite joint uses more of a triangular shaped retainer bead. This difference may seem meaningless, but it has proven to be a cause of many headaches over the years. Even though a Tyton gasket may initially fit into a Fastite bell, or vice versa, it is not recommended. The specific designs of these joints allow the retainer bead and gasket heel to work in tandem to ensure the gasket will not be pushed out of the joint during assembly which could result in a leak.

No matter the factors that contributed to the purchase decision, there is a good chance that at some point you may install pipe supplied by one of the three domestic manufacturers of Ductile iron pipe; American Cast Iron Pipe Company, US Pipe and Foundry, or McWane Ductile. Therefore, we want you to know the differences before you have a leak that could have been prevented.

At the end of the day, a minimal-cost gasket is not worth the time, effort, and money it will take to find and fix a leak due to a pushed or rolled gasket. So, make sure that you have the proper gasket for joint type that is being installed. Check out another one of our Iron Strong blogs on how to avoid displacing or rolling a gasket by McWane Ductile Sales Rep, Jason Barnes.

Does restrained pipe use a different gasket than non-restrained joint pipe?

Push-on, restrained joint pipe -- whether TR Flex® manufactured by McWane Ductile and U.S. Pipe, Flex Ring®, manufactured by American Cast Iron Pipe, or HP Lok®, manufactured by U.S. Pipe -- use the same gasket as used by the manufacturer in their corresponding non-restrained joint pipe (i.e. Tyton Joint® gasket for McWane Ductile and U.S. Pipe or Fastite® gasket for American Cast Iron Pipe).

Are locking gaskets interchangeable between the different DI Pipe manufacturers?

The answer to this question is the same as the question about push-on joints. Sure Stop 350® and Field Lok 350® gaskets can both be used with the Tyton joint. It doesn’t matter which manufacturer's pipe or gaskets are being used. However, neither of these gaskets should be used with American Cast Iron Pipe’s Fastite joint. Therefore, the American Fast-Grip® gasket should only be used with their Fastite pipe.

There are other locking gaskets out there that are not manufactured or recommended by the pipe manufacturers. What you need to guard against is using any gasket that is not approved by the pipe manufacturer.

All gaskets that are made for use with a specific brand of pipe must be manufactured by a licensed manufacturer. Essentially, the owners of the pipe joints, U.S. Pipe for Tyton® and American Cast Iron Pipe Company for Fastite®, must issue license agreements to the individual gasket manufacturers. If you decide to allow or install gaskets manufactured by a non-licensed gasket manufacturer, the pipe warranty could be voided.

And remember, once you have the gaskets on the jobsite, be sure to care for them them properly. For tips on proper gasket storage, see our blog by Josh Baker, McWane Ductile Sale Rep.

Want more tips and instruction to help your team succeed in the field?

Please contact your local McWane Ductile Sales Rep to request a Lunch & Learn, a Day of Water, or on-site training before installing your next ductile iron pipeline. We provide free training and education to suit your needs. Thanks for taking the time to read this Iron Strong blog.

Check out our other digital offerings: