The Town of Andover, located in the northeastern corridor of Massachusetts, provides water service to over 10,000 customers in a network of approximately 257 miles of water mains, the oldest dating back to 1886. This #IronStrong blog tells how the Andover Water Division solved a significant water loss issue due to a breach in one of their important mains feeding a commercial/industrial area.

A Major Breach = Loss of Water Pressure

On February 1st, the Andover Water Division received “that dreaded call” from a commercial user experiencing water pressure issues in their facility, which relies heavily on water for cooling towers and various processes. Water Division Superintendent Jeffrey Crane and Crew had a very good idea of what was causing the loss in pressure, potentially from a section of the main that had caused issues in the past.

The breach in the system was located on a 12-inch 1960s vintage cast iron main believed to be manufactured by the R.D. Wood Company of Philadelphia, PA. The 12-inch Mechanical Joint main crosses the Shawsheen River, which was where the breach in the main had occurred. This section of the main was isolated quickly to minimize water loss from the system.

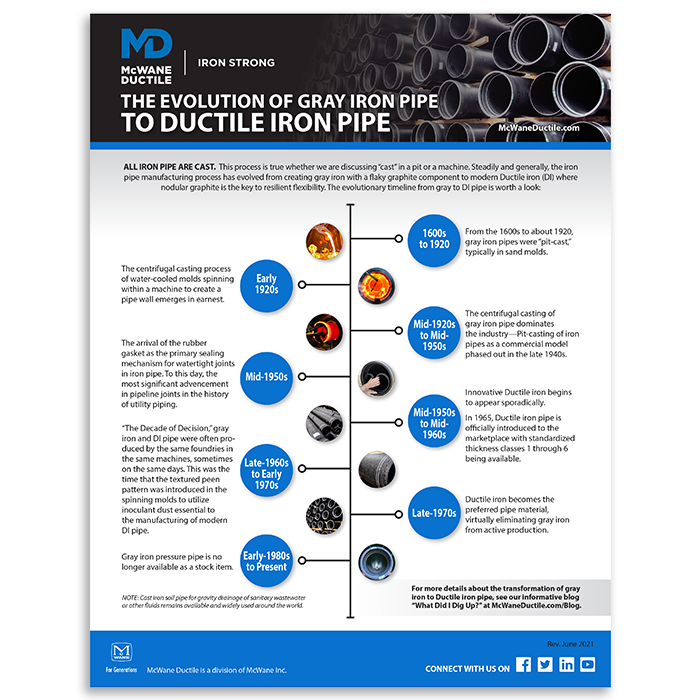

When did Grey iron pipe evolve to Ductile iron pipe? Download this free and helpful timeline tip sheet from McWane Ductile!

Who Did the Water Utility Call for Repair Assistance?

Jeffrey Crane quickly put an emergency repair plan into motion. Steven Granese of N. Granese & Sons, Salem, MA, was alerted of this water pressure issue and the need for this pipe to be replaced as quickly as possible. Todd Prokop, Project Manager at Woodard & Curran, was contacted to provide engineering support in defining the existing pipeline location, determining a pipe replacement plan, and obtaining the necessary emergency permits required to enter the wetland and replace the pipe in question.

What Was the Solution for the Water Loss?

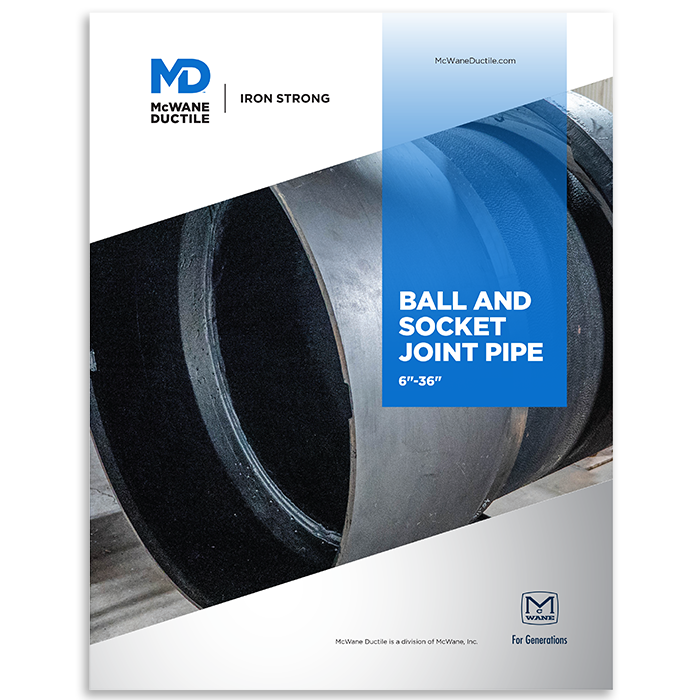

Ductile iron pipe with a Ball and Socket Restrained Joint configuration was selected to facilitate crossing the Shawsheen River. Class 55 Cement-Lined Ball and Socket pipe was selected based on this waterway application as well as the use of the 15 degrees of deflection at each 18-foot joint allowing the pipe to conform to potential slopes that may be encountered while crossing the waterway.

The restrained joints of this product were necessary to enable the installing contractor to pre-assemble the pipe and pull the pipe across the river and into place without fear of joint separation. This allowed Granese to install the pipe quickly without needing to dam, bypass, or dewater the river, thereby reducing the construction's impact on the wetland resource areas.

Who Did the Water Utility Call for Product on Such Short Notice?

Steven Granese contacted partner material supplier John Needham at Ferguson Waterworks- North Reading, MA. He explained the emergency repair they were now involved in, the material required to make the crossing, as well as the need to have ALL material on-site by February 15, 2023. Given the tight deadline, John contacted Senior Sales Representative Jeff Houser at McWane Ductile to determine if this specialty product could be sourced and delivered to the site.

Crossing a river, lake, or bay? Assemble your Ball & Socket Joint Pipe correctly with these free, helpful instructions from McWane Ductile!

DOWNLOAD NOW

How Did the Pipe Manufacturer Respond to the Tight Request?

Houser contacted Technical Services Specialist Cory Humphreys at the McWane Ductile Ohio facility to determine if the team could accomplish such a request. Cory worked with the appropriate staff in the facility, including sales, production, and machine shop. Based on the availability of in-house material and components, department heads met and ascertained that the deadline could be met as this emergency project was a priority.

The machine shop crew in Ohio began cutting and threading the 12-inch Class 55 Ductile iron pipe to accept the Ball and Socket bell and ball that would be threaded onto each end of the host pipe. Upon completing fabrication, each joint was tested for fitness. Once the pipe met all necessary testing requirements, it was prepared for shipment. The pipe was loaded and delivered to the site on February 15, meeting the material delivery deadline.

Meanwhile, Crews Prepped the Site for Pipe Installation

During this time, Andrew Hamilton & N. Granese's crew began preparing the site to facilitate this crossing. Test pits were required to locate the existing pipe, as well as sheeting and shoring the area around the existing pipe to facilitate dewatering and access for cut and cap, as well as the final connection of the replacement pipe.

Steven Granese commented, "We appreciate the efforts both McWane Ductile and Ferguson Water Works put forth. They fabricated, tested, and delivered the pipe in less than two weeks, and they had technical support ready and waiting on-site to assist with the pipe assembly and installation. With the supply chain issues the market has faced over the past three years, having vendors that understand and support an emergency effort means so much, more than ever."

Additional measures were taken by the Town of Andover and Woodard & Curran in monitoring soil and water conditions to minimize impact and directing N. Granese crew to install dual turbidity curtains to contain the side effects of removing and replacing the ailing pipeline through the waterway.

Removing the Old and Installing the New

Following the location of the existing pipeline on both sides of the crossing, shoring, and sheeting each connection pit, N. Granese's crew began locating and removing the existing pipe from the waterway.

McWane Ductile was on-site to provide guidance on the handling, assembly, and installation of the Ball and Socket pipe. The final steps required to complete this crossing involved attaching a cable to the bell end of the assembled Ductile iron Ball and Socket River Crossing Pipe and pulling this pipe into place. That would be the easy part.

The real work began in positioning the new ball and socket pipe to mate up and connect to the existing pipe on either side of the crossing. Having these two connection pits open and excavated to the appropriate installation grade allowed river water to fill each pit. Once the new pipe was in close proximity to make the connection, earth dams and dewatering would be required to allow N. Granese crews a safe workspace inside the connection pits.

Final connections were made at each side of the crossing. The main line was filled with water at system pressure and determined to be fit for service as no fluctuation in pressure was found. Final flushing and chlorination were required before restoring water service to the affected customers along this section of the main.

A Solid Emergency Plan + Teamwork = Water Restored

Water Division Superintendent Jeffrey Crane commented, "We had a large-scale pipe failure under the river on this main in 2020. This was the second one in less than three years. We did not want a third. Granese has successfully performed difficult utility repairs for us in the past. We were pleased that McWane Ductile could deliver this specialized product under such tight time constraints."

From start to finish, this project was completed in 14 working days. The emergency plan allowed a safe and well-thought-out course of action to remove and replace an aging section of the main that will now provide generations of reliable service through this updated mainline.

Todd Prokop of Woodard & Current commented, “The failed water main was a critical component of the Town's distribution system. It was imperative to get it replaced as quickly as possible. McWane Ductile and Ferguson committed to an aggressive schedule and kept their promise to help the town meet that goal.”

For more information on Ball and Socket River Crossing Pipe application and installation, visit my previously published #IronStrong Blog by clicking on the following link: https://mcwaneductile.com/blog/what-are-common-installation-methods-for-ball-socket-river-crossing-pipe-and-how-is-it-assembled/

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, contact your local McWane Ductile representative. We have team members who've managed small and large water utility systems and served in engineering consulting firms, providing decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.