Ductile Iron (DI pipe) was first used in the United States as early as 1950's. Since iron pipe was one of the earliest pipe materials to be used in modern water works and wastewater systems, most early fittings and couplings were designed to be used on Grey Cast and then Ductile iron pipe.

So, connecting “other” piping material to DI pipe is very straightforward on the Ductile side of the fitting. The most important item to consider is on the other material side of the connection.

The following information is generally in reference to pressure pipe applications starting at three inches in diameter and over. This is also in reference to connecting pipe in line and not a tap or branch connection.

DI pipe can easily be connected to other materials in pressure applications using very common fittings and by using some very specific fittings or couplings.

Mechanical Joint Fittings

One of the most common connections from DI pipe to other pipe is with the use of Mechanical Joint Fittings (MJ). Since DI pipe is manufactured to an industry standard “Outside Diameter” (OD), no matter the manufacturer, all DI pipe will have the same OD in each size.

Since MJ fittings were originally designed to be used on DI pipe, no special considerations are needed for the DI pipe side of the fitting.

When using MJ fittings on other pipe, if the OD of the pipe is not ductile iron pipe size, special transition gaskets must be used to make up the difference in the pipe ODs.

What About Polyvinyl Chloride (PVC)?

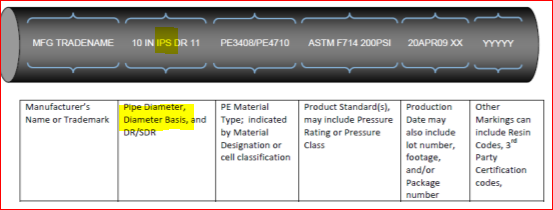

A mentioned above, special transition gaskets are needed when connecting Iron Pipe Size (IPS) PVC pipe, IPS HDPE pipe, or steel pipe. ODs can be found using industry standard OD charts. The OD reference, if not the actual OD, should also be clearly marked on new pipe.

When connecting to any PVC pipe, special attention needs to be taken to ensure the type of PVC pipe and subsequent ODs are known when making the connection.

The PVC Pipe Association guide, “Making Sense of Diameter Types for PVC,” is a good source to reference what type of pipe and resulting OD you may run into.

If restraint is to be used at the fitting, special care must be taken to ensure the correct restrainer is used on the correct pipe material. Using a DI restrainer on PVC pipe may damage the pipe. Using a PVC restrainer on DI pipe may not provide the proper torque needed to restrain the pipe.

High Density Polyethylene (HDPE) Pipe

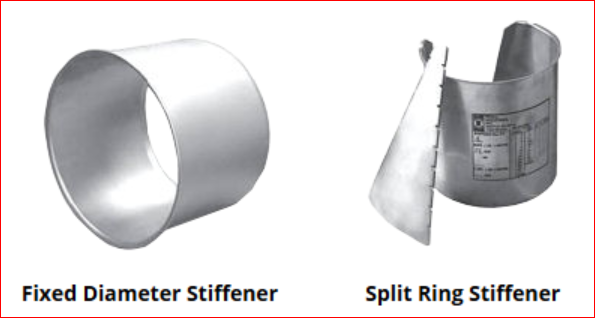

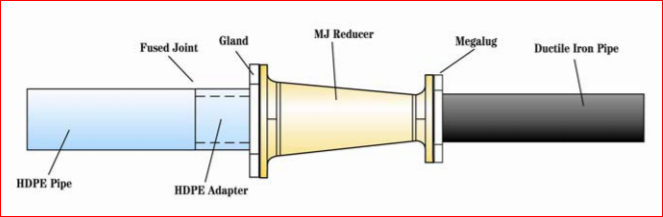

If connecting High Density Polyethylene HDPE pipe, an MJ adapter or an internal “stiffener” will be required in the “Inside Diameter” (ID) of the HDPE pipe to support the MJ compression connection. This stiffener must be sized based on the (ID) or wall thickness, or DR of the HDPE pipe being used.

Some common examples of installations using different pipe in MJ fittings might be a connection on a fire riser at a building, or transitioning to and from HDPE used for a directional drill. Pipe can also be transitioned from one type to another at a MJ valve, the same way as an MJ fitting.

Transition Couplings

There are many manufacturers that make all types of couplings, clamps, restrainers, fittings, and devices that can connect DI pipe to any other type of piping material or fitting needed. Most couplings that are manufactured in the water works industry were originally designed to be used first on DI pipe, and then later, on other materials.

The coupling to be installed must first be the correct nominal pipe size and have the correct “range” for the pipes being connected. The OD of the pipe must be within the “minimum and maximum” OD range for the coupling.

This is true for the ductile iron side as well. The only consideration to keep in mind would be to check the DI pipe OD to ensure the pipe is within the correct OD range.

This is especially true if you have a large diameter pipe or you have cut the pipe you are connecting. On cut-pipe 14 inches in diameter and larger, you should use pipe that has been marked as “gauged” if possible, and make sure any cuts are at least 2 feet from the bell. This should ensure that the pipe OD is within spec.

If possible, check the pipe in the field with an OD tape. You can also “field check” the pipe where you are going to connect the coupling by sliding a MJ gland over the pipe where you are connecting the coupling/fitting. Once this is done, you simply connect and tighten the coupling/fitting per the manufacturer’s recommendation.

The material used on the other side of the coupling, along with the coupling manufacturers recommendation, will determine what steps need to be taken to connect the other pipe material.

Again, the OD of the other pipe will need to fit within the min – max range of that side of the coupling. Depending on the material, insert stiffeners may be required as well.

If restraint is to be used for this connection, as mentioned above, different types of restraint methods may be required on the DI pipe side versus the “other” material side of the coupling as well.

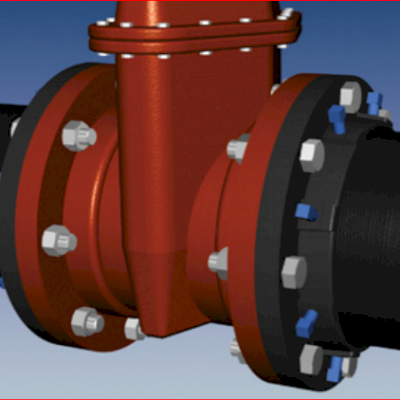

Connecting to Flanges

Flange adaptors, flange coupling adaptors, EZ Flange, Uni-Flange, and other products can be used to connect a DI pipe to a flange connection.

Again, the coupling or adaptor must be the correct size and range for DI pipe. These devices can come in restrained and non-restrained configurations.

Every manufacturer will have their own specific instructions on how to assemble and tighten the connection for their coupling on the type of pipe being used. Please be sure to follow the manufacturer’s recommendation for their product and the pipe being used.

Inserting DI pipe into a PVC pipe bell (DI Size PVC) or inserting DI OD PVC pipe into a DI pipe bell should technically work, when no other means are available.

Considerations for this application are, the depth markings on the pipe being inserted must be adjusted to accommodate the depth of the bell that the “other” pipe is being inserted into.

If there is an issue with the joint after installation, the manufacturers of the two pipes may not be able to provide help with their material connecting to the other material.

And last, when restraint is required, one manufacturer’s restraint method may not apply to the other manufacturer’s material. For example, a DI restraint gasket may not work on PVC pipe that is designed to work on DI pipe.

When connecting DI pipe to an existing steel pipe, concrete pressure pipe, AC, or other pipe, it may be necessary to expose the existing pipe to determine the type, size, OD, and if possible, manufacturer of the existing pipe. Many types of pipe will require custom-made couplings to make the connection to DI (or any other) pipe.

In some cases, the pipe manufacturer may need to make this adapter. There are many coupling manufacturers that can make couplings for the exact material you are connecting, once you have determined the type, size, and OD you are connecting.

I have listed several companies that manufacture standard, and special, custom-made couplings that should suit any application you have. Your local McWane sales representative or McWane distributor will be able to help you find the best option when connecting DI to other pipe materials. You should refer to the recommendation of the pipe manufacturer AND the coupling/fitting manufacturer when installing any pipe.

References

Graphics and references in this article are from: DIPRA, PPI, Uni-Bell, Tyler/Union, Romac, JCM, ansd Ebaa Iron. Other manufacturers of couplings and connections for different pipe are, Smith-Blair, Ford Meter Box, Power-Seal, Robar, Nova-Siria, Hymax, Krausz, and Teekay, among others.

Need Assistance With Your Water Infrastructure Project?

McWane Ductile offers multiple services for our customers extending far beyond manufacturing ductile iron pipe. From design to installation, we take great pride in providing education and training to water professionals throughout the water and waste water industry. Together, we are Building Iron Strong Utilities for Generations!

Check out all our digital offerings: