The landscapes and environments in which we live are constantly changing, and ensuring that resilient infrastructure is in place to support local communities is a priority for all cities. In regions where natural disasters occur and pose significant threats, such as wildfires and earthquakes, and as seen most recently in areas such as Lahaina, Hawaii, and the Palisades in the Santa Monica Mountains of Los Angeles County, California, Ductile iron pipe (DI pipe) has proven to be a durable and reliable choice for water infrastructure. This article will discuss why selecting the proper material for underground infrastructure is crucial in combating natural disasters and enabling communities to respond more effectively with a reliable source of potable water and vital fire protection.

Resilience

The strength of Ductile iron pipe, combined with the most conservative design for pressure pipe applications, enables DI to provide the highest levels of resilience to environmental hazards such as wildfires and the everyday stresses from pipeline traffic and internal pressure demands. The National Infrastructure Advisory Council (NIAC) defined infrastructure resilience as “the ability to reduce the magnitude and/or duration of disruptive events. The effectiveness of a resilient infrastructure depends upon its ability to anticipate, absorb, adapt to, and/or rapidly recover from a potentially disruptive event” (NIAC, 2009).

Wildfires & Pipe Resilience

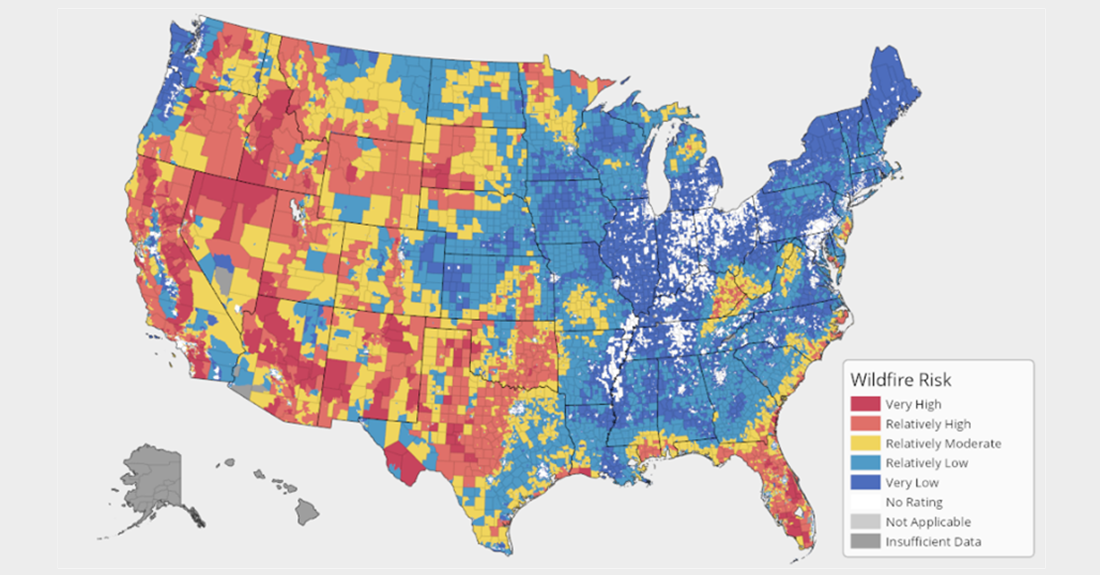

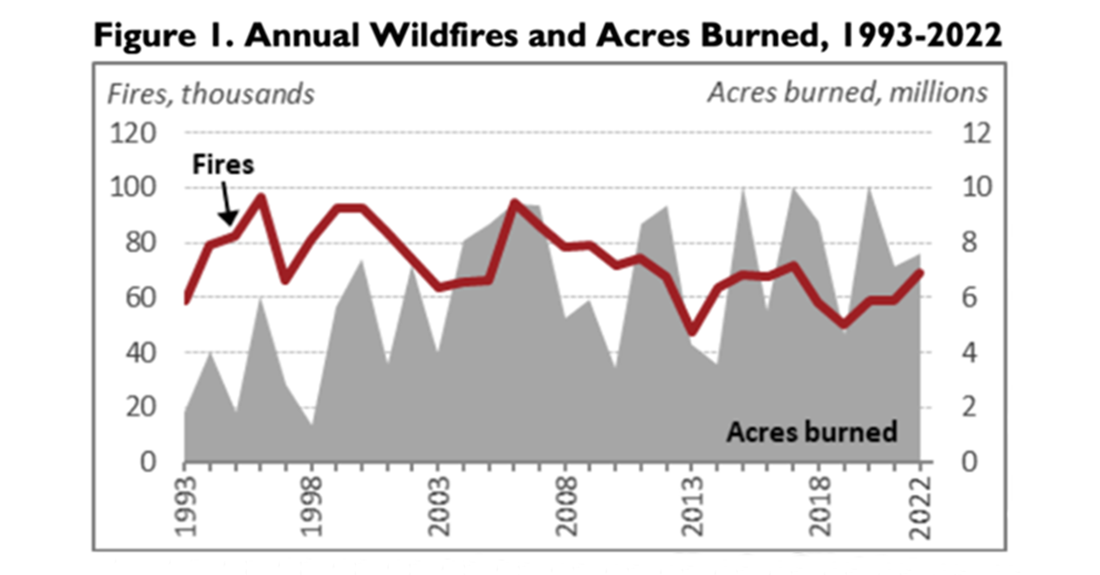

Changing weather patterns have significantly impacted water and wastewater utilities. One of the highest threats is the increased likelihood of wildfires, which have caused an average of 62,277 wildfires annually and resulted in an average of 7.02 million acres of land being lost each year. These wildfires have devasted communities, contaminating drinking water and destroying infrastructure and homes, forcing emergency evacuations.

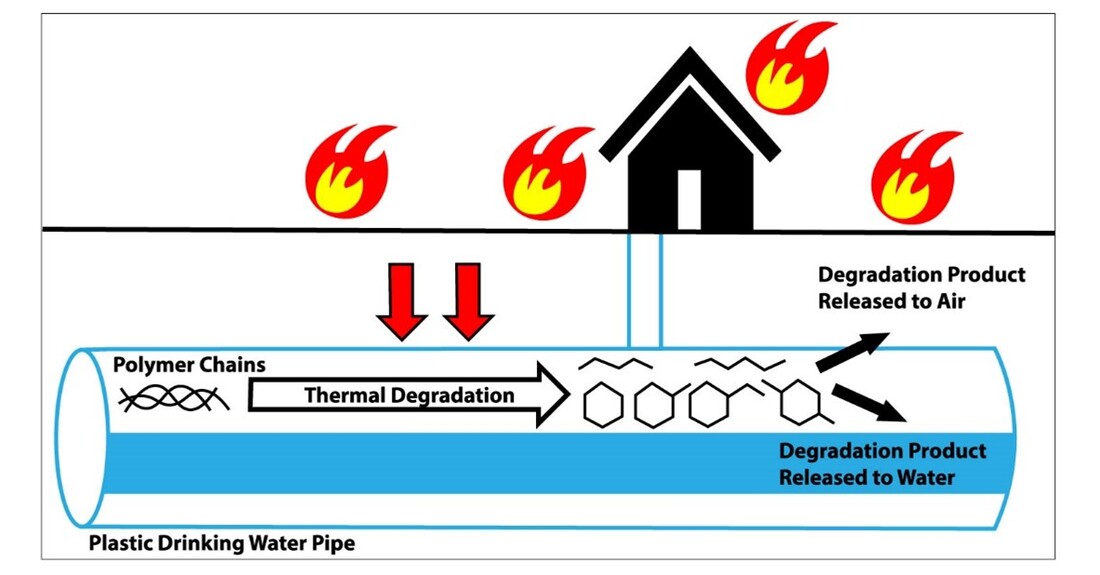

Wildfires present substantial challenges to plastic pipes, both directly and indirectly, due to excessive heat. The heat generated in wildfires often hampers firefighting efforts while also creating temperatures that exceed the melting point of buried plastic pipes, causing water contamination and pipeline failures.

Thermoplastics located downstream that have been structurally affected by heat but have not been completely melted are susceptible to failure when pressure is reintroduced. In addition, Polyvinyl Chloride (PVC), among all plastic polymers, has been primarily implicated in causing the most severe problem in firefighting today, as PVC plastic pipes release hydrogen chloride gas when they melt in a fire. Similarly, many plastics produce large volumes of pulmonary irritant gases when burned, posing a significant and potentially fatal risk to the health of firefighters and residents. (U.S. Environmental Protection Agency).

“While the immediate danger of flames is evident, the long-term health effects of burning materials—especially plastics—are only beginning to be fully understood. As homes and buildings burn, so do the plastics inside them…These materials release a cocktail of chemicals linked to a plethora of health issues, such as cancer, respiratory problems, organ damage, and water contamination. (DIPRA Minute 2025).”

When PVC pipe is exposed to high temperatures, its tensile strength decreases, resulting in reduced performance and pressure rating. Extreme heat from wildfires can cause warping, expansion, contraction, joint buckling, or even melting of PVC pipes. In contrast, manufacturer tests have shown that Ductile iron pipe remains stable and fully functional when subjected to direct flames and temperatures exceeding 2,000º F.

-

San Lorenzo Valley Water District leaders have planned to replace pipelines that supplied the Lyon Water Treatment Plant with creek water and connected the plant with its main storage tank. The pipelines melted in the CZU Lightning Complex Fire. Image Source: San Lorenzo Valley Water District -

Melted plastic was all that remained Aug. 21, 2020, of a pipeline that supplied the Lyon Water Treatment Plant after the CZU Lightning Complex Fire ravaged the area near Boulder Creek. Image Source: San Lorenzo Valley Water District.

Case Studies: Strength Against Wildfires and Regulatory Concerns

Recent research from Purdue University has focused on the impacts of wildfires on buried pipelines, revealing that drinking water has become contaminated by PVC, High-Density Polyethylene (HDPE), and Chlorinated Polyvinyl Chloride (CPVC) plastic pipes. This adds to years of studies documenting the environmental impact, lack of sustainability, shorter design life, higher pumping costs, and reliance on petrochemical resins over natural elements. Additionally, there is a risk of drinking water contamination through permeation from plastic pipes.

Following the Palisades and Lahaina fires, Professor Andrew Whelton criticized public utilities for not sharing water testing results post-disaster, highlighting the absence of federal or state laws mandating such transparency. Recently, utilities in both the Eaton and Palisades fire areas detected benzene carcinogens in their water supplies. This prompted the Los Angeles Department of Water and Power to create an online dashboard informing residents of restoration progress under "Do Not Drink" advisories. Increased federally mandated drinking water testing after disasters is hoped for.

Furthermore, the EPA's ongoing investigation into Vinyl Chloride, a known human carcinogen linked to serious health risks, will likely lead to stricter regulations. As this research progresses, continued testing for contaminants in PVC systems, including microplastics and benzene, is expected.

Lahaina, Palisades, and Other Critical Events

Lahaina’s recent wildfires emphasize the need for fire-resistant infrastructure. Unlike plastic pipes, which can melt at low temperatures (PVC at 212°F, HDPE at 275°F), Ductile iron pipes can endure temperatures over 2,048°F, safeguarding critical water supply and infrastructure for residents and first responders in wildfire-prone areas.

Ductile iron pipe is manufactured by melting recycled scrap metal at approximately 2,700°F. Most wildfires average 1,400°F, with temperatures nearing 2,000°F in extreme cases. Even though these temperatures are well below the melting point of Ductile iron pipe, controlled studies have demonstrated the resilient performance DI pipe in a wildfire scenario. The study burned a DI pipe joint at 1,500°F for 45 minutes to determine the impact on the assembled joint system. After surviving the 45-minute simulation and exhibiting no structural degradation, the pipe joint was pressure-tested at 500 psi for 10 minutes, with no leaks detected.

Similarly, the Palisades—primarily associated with seismic activity—have also experienced devastating fires. Ductile iron pipes and hazard-resilient joints can absorb seismic shocks while ensuring serviceability, reducing the risk of catastrophic water system failures. Lahaina and the Palisades need infrastructure that can withstand environmental challenges and minimize costly repairs. With a lifespan exceeding 100 years*, Ductile iron is a cost-effective choice for sustainable water systems. Its strength and proven performance in harsh conditions make it essential for building resilient infrastructure.

As climate challenges grow, specifying and installing robust materials like DI ensures that water systems remain operational. Investing in such infrastructure today leads to a safer, more reliable future for regions like Lahaina and the Palisades. Recent events like the 2018 Camp Fire and 2017 Tubbs Fire have linked harmful chemicals like benzene to plastic distribution pipes. Contamination can persist for months, as seen in the Tubbs Fire, where it remained for nearly 11 months, highlighting the risks associated with plastic piping in wildfire-prone areas (DIPRA).

Summary

Pipelines are vital infrastructures that provide potable water and fire protection. Ensuring you have selected the best, strongest material when designing critical infrastructure is the first step in prioritizing communities' health and safety. It’s not a matter of if…but a matter of when.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is equipped with the expertise to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

References

- “Surviving the Quake.” U.S. Environmental Protection Agency. March 26, 2018. Accessed January 20, 2025.

- “Liquefaction San Francisco, 1906 earthquake.” IRIS Earthquake Science. April 6, 2011. Accessed January 20, 2025.

- Ductile Iron Pipe Research Association, “Longevity.” Accessed March 1, 2025.

- U.S. Environmental Protection Agency, “Risk and Resilience Assessment Requirements and Assistance Resources.” Accessed March 1, 2025.

- U.S. Environmental Protection Agency, “Baseline Information on Malevolent Acts for Community Water Systems.” Accessed February 5, 2025.

- U.S. Environmental Protection Agency, “Creating Resilient Water Utilities.”Accessed January 20, 2025.

- Ductile Iron Pipe Research Association, DIPRA Minute: “Proven Resilience of Ductile Iron Pipe.” August 17, 2021.

- Resiliency, (Great maps in Civil Engineering Magazine, September 2019 issue).

- “Local Buckling of Buried HDPE Pipelines Subjected to Earthquake Faulting.” Case Study Via Numerical Simulations and Experimental Testing Xiaojian Xie,Michael D. Symans,Michael J. O’Rourke,Tarek H. Abdoun,Da Ha,Thomas D. O’Rourke,Michael C. Palmer,Jeremiah Jezerski &Harold E. Stewart. Published online: 20 Nov 2017