In this second installment of our Iron Strong Blog on Sustainability and Resiliency, we will focus on recycling and the recyclability of various pipe materials. As you may know, Ductile iron pipe is made from recycled iron and steel scrap, making it not only a recycled product but a recyclable product.

Okay, since that fact has been stated, why read further? Well, besides being the only primary full-size-range piping product made from recycled material, you should know why this is important to you, me, and everyone else. We will look at the impact of recycling on cities and towns as well as countries and the planet.

Recycling and Its Importance

Why is recyclability vital to us? We live on a planet with what we now realize are limited resources. While we most often think of these resources as things such as oil, gas, and minerals, we now recognize these resources to be so much more than even air and water.

Resources that are important to us today include our health and quality of life, as well as plants and animals and their ecosystems. This includes having air and water that are free of carcinogens and harmful chemicals. And it also includes limits on waste disposal.

Unfortunately our society has been somewhat slow to understand how critical these resources are for our planet’s survival. Some of these lessons we learned the hard way, but we did learn their importance. With the knowledge of the consequences we've obtained over the years, we are better educated to make sound decisions to protect these resources for generations. In recognition of all of these factors, most municipalities, counties, and states have developed recycling programs, and the United States Environmental Protection Agency (EPA) has useful information for consumers to help them with their recycling efforts.

A few of us may recall in our younger years when recycling consisted of bringing back thick and heavy empty glass soda bottles that were cleaned and refilled. While glass is still recycled, it is done a bit differently today with fewer bottles being refilled (direct reuse) and more likely being crushed and re-manufactured into new glass containers - much the way iron and steel are recycled.

Methods of Recycling

Today, recycling is accomplished through different methods, and there are two primary types of recycled materials: Post-consumer and Post-industrial.

- Post-consumer is what we would typically see disposed of in Municipal Solid Waste (MSW), for instance, our curbside recycling bin or disposed appliances and vehicles.

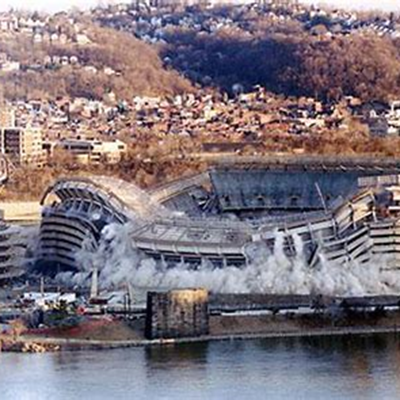

- Post-industrial is what is typically disposed of from demolished structures such as stadiums, old replaced bridges, and aged out-of-service ships. Post-industrial scrap was abundant after World War II and the EPA has developed data on MSW dating back to 1960.

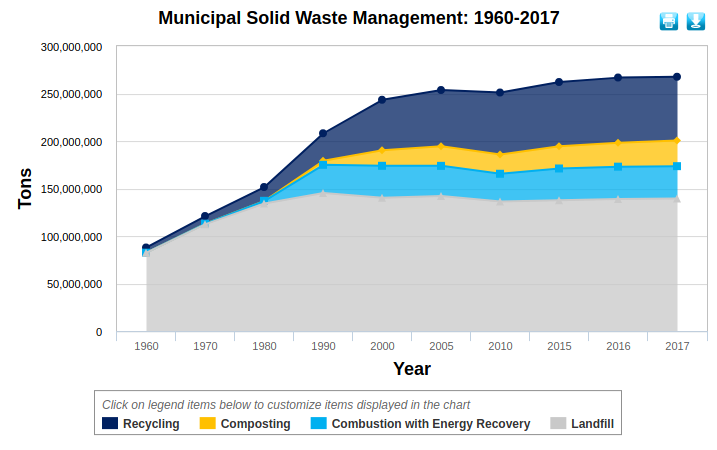

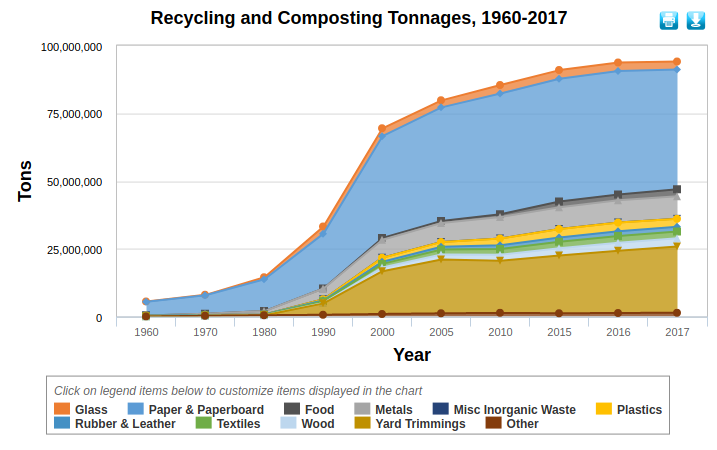

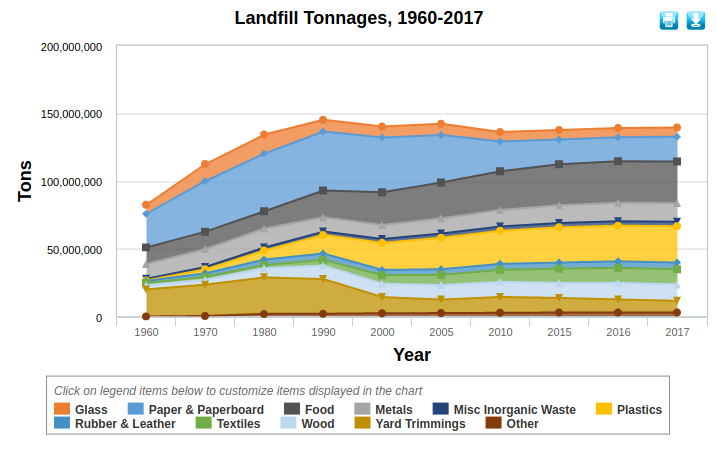

While MSW land-fill has leveled off and recycling has increased per annum, we are still compiling waste in landfills at nearly 150 million tons of MSW per year, reducing the resource of usable landfills available. MSW is land-filled at over twice the rate of recycling. This aggressive rate emphasizes the need to increase the speed of recycling. There are two ways to meet this need:

- Increase the use of recyclable materials over lesser recycled materials.

- Push up the rate of recycling for other lesser recycled materials.

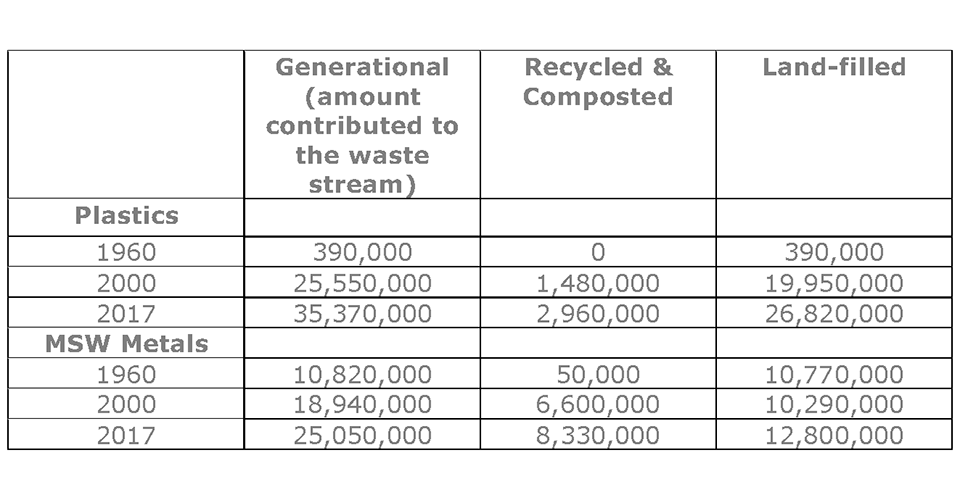

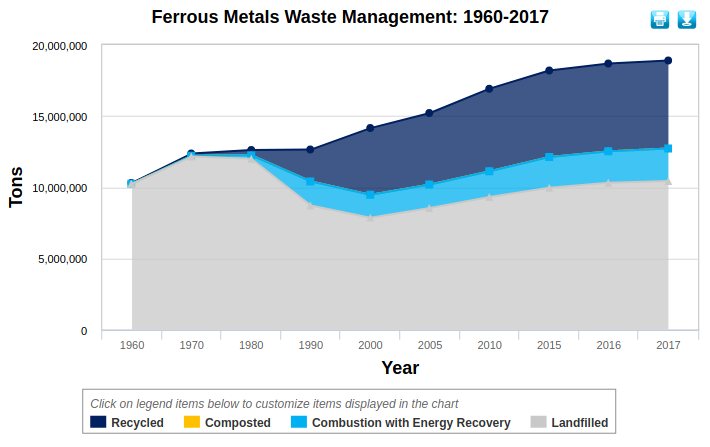

From the EPA's data on MSW, we can compare some information to help us better identify materials that are more recycled and recyclable in the table below:

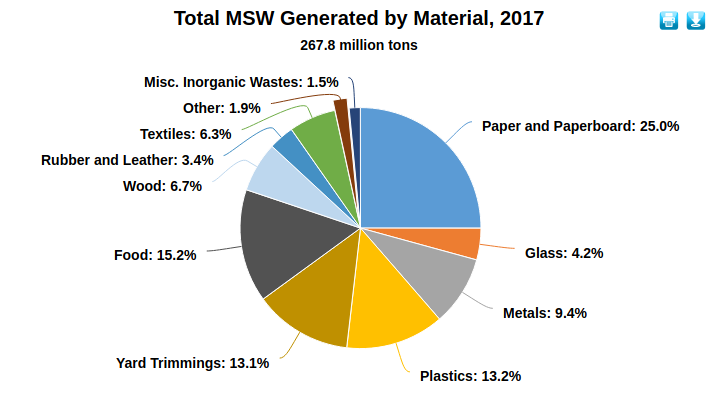

Further, in 2017, metals accounted for 9.4 percent of Generational Materials versus 13.2 percent of plastics. Yet, metals accounted for 8.8 percent of Recycled and Composted with most of that being recycled, but only 3.1 percent of plastics was Recycled and Composted. Additionally, of materials landfilled, plastics accounted for nearly 20 percent of all landfilled materials in tons, while metals were less than 10 percent of landfilled materials. This information can help identify the more environmentally recyclable materials (metals obviously) when making selection decisions.

Today, virtually every municipality, county, region, state, or province has a recycling program. Participation in these programs is often mandatory, which is reflected in the EPA's data showing higher recycling rates.

This has, however, created somewhat of a dilemma in that there is now a greater supply of recycled materials than demand for recycled materials. This dilemma results in materials placed into recycling bins, eventually being land-filled instead of recycled. Sustainability conscious municipalities, counties, utilities, and states often do not consider whether what they are buying is made of recycled materials and the more profound impact of those decisions.

It would be common sense to expect that an entity wanting its residents to recycle, promoted its use of and made an effort to use recycled products over non-recycled products, that their program would be more positively received. Every Government entity that has a recycling program should be asking:

- How much of the materials we use are recycled?

- How much of an effort do we make to utilize recycled materials?

- When we do use recycled materials, do we let our citizens/residents/ratepayers know, so they are aware of our commitment to the environment and program?

While saying there should be legislation to require recycled material use or content is easy, at McWane Ductile we advocate for Local Choice and not legislation that forces communities to purchase products or materials that do not fit their needs and goals. Forcing people to do things they do not support does not foster the growth of the needed support for the longer goal of protecting vital resources.

Recycling and Pipe – All Pipes Are Not Equal

Why does all this matter when considering pipe materials? Aren't factors such as performance capabilities and cost the overriding considerations? Most often, the answer is simple; the best, most capable, long-term, cost-effective pipe available is Ductile iron pipe.

And if corrosion is a consideration, it is easily addressed with the availability of multiple solutions such as zinc coating and/or V-Bio polyethylene encasement. However, occasionally, the questions involve more detail, and the cost analysis requires more depth.

In these considerations, it is equally as simple. Iron pipe, even over 100 years old, can be melted down and recast into new Ductile iron pipe. This recasting process is done every day. Whether it’s old pipe, steel wheels, old house radiators, engine blocks, and cars (so that's what happened to all those Yugos?!), refrigerators, washers and dryers, structural steel, we recycle it into new McWane Ductile iron pipe that will last for generations.

Other pipe materials cannot claim to be made of recycled materials, and many cannot be made of recycled materials even if they wanted to. Their performance degrades with time and temperature, two factors on which recycling often depends. This is especially true with plastics, as even their product standards require virgin raw materials.

Instead of helping to solve the problem of conserving resources, plastics drastically increase the loss of resources. Plastics increase the use of resources on their own and decrease the conservation of resources and recycling of other materials for which they are substituted. This creates a type of double jeopardy.

Iron and steel are easily recycled by melting, where metallurgical composition can be easily monitored, treated, and adjusted to obtain the best quality and performance. In the rare case that manufactured iron pipe that does not meet requirements, it can easily be re-melted with other scraps. If there is a simple physical manufacturing defect, the iron pipe can be inserted in processed molten iron in cases of high temperatures. This re-insertion provides slightly cooler iron (think an ice cube in your glass of water) without affecting the chemical composition and is referred to as "chill iron."

Where does plastic pipe that does not meet spec go? It often goes straight to a landfill, taking up more space and wasting more limited resources. This is not an environment or a future anyone wants, so to specify environmentally friendly, recycled Ductile iron pipe from McWane Ductile is the responsible choice!

For help and/or information on how Ductile iron pipe can make your system more Sustainable and Resilient, please contact one of our ENVISION Sustainability Professionals (EnvSP) or contact your local McWane Ductile representative.

We also have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

Sources

- https://www.epa.gov/waterresilience/americas-water-infrastructure-act-risk-assessments-and-emergency-response-plans#RRA

- https://www.epa.gov/waterriskassessment/baseline-information-malevolent-acts-community-water-systems

- https://www.epa.gov/crwu

- Green Infrastructure Briefs, (2016-2017) Hannah J. Brown, USGBC

- American Water Works Association (AWWA) (2015). “Buried No Longer: Confronting America’s Water Infrastructure Challenge.”

- Design of Water Supply Pipe Networks, Swamee and Sharma

- A Framework to Evaluate the Life Cycle Costs and Environmental Impacts of Water Pipelines, Thomas, Mantha, and Carol C. Menassa, University of Michigan

- Ductile Iron Pipe Research Association (2015). “GUIDELINES Installation Guide for Ductile Iron Pipe”, DIPRA

- Ductile Iron Pipe Research Association, https://www.dipra.org/ductile-iron-pipe-resources/technical-publications/tapping

- Ductile Iron Pipe Research Association, https://dipra.org/ductile-iron-pipe-resources/downloadable-brochures/celebrate-sustainable-infrastructure-brochure

- The Institute for Market Transformation to Sustainability: http://mts.sustainableproducts.com/SMaRT_product_standard.html