How often have we heard a developer tell a utility they simply can’t afford to install Ductile iron pipe (DI Pipe) for a planned subdivision because it’s too expensive. After all, the developer is providing the water and wastewater mains for free, transferring ownership to the local utility usually after one year.

Don't Forget the Other Factors

Unfortunately, the developer doesn't have a vested interest after that one year. They often site that DI pipe costs more than twice as much as Polyvinyl Chloride (PVC) on a price per foot - ignoring many of the factors relating to a successful long- term installation, as well as design life and lower energy and repair costs that are in the best interest of the utility.

Factors beyond the initial price-per-foot of the pipe such as:

- Bedding

- Tapping saddles

- Line locator wire

- and Corrosion Protection.

The utility might also prioritize the sustainability/environmental cost and design life when specifying pipe material for developments.

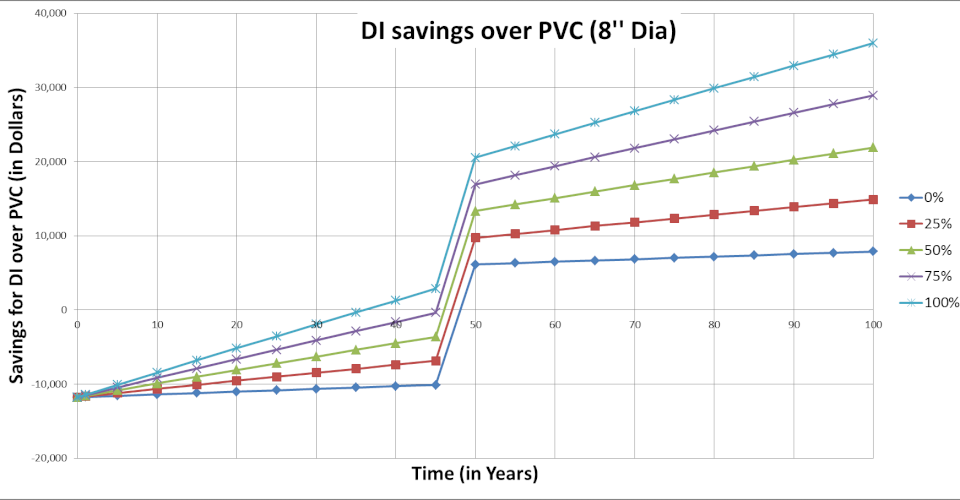

When these real costs are considered, the initial Lot Cost differential is minimal. Similarly, if the utility employs the University of Michigan Life Cycle Cost Studyand the AWWA Buried No Longer Study for material selection, they have the opportunity to significantly increase sustainability and in many regions of the United States, virtually doubling the design life of mains by specifying DI pipe versus allowing developers to use PVC.

Let's Calculate!

To illustrate, let’s begin with a detailed breakdown of the installation cost of PVC vs DI pipe using one mile of 8-inch diameter pipe and commonly used 65-foot lot size (with lots on both sides of the street) totaling 162 lots per mile.

Calculations listed here are based on current market price at the time of this publication, November 2019.

PIPE BID PRICE | ||

| 8 Inch PVC C900 | 8 Inch DI Pipe | |

| DR18 | PC 350 | |

| $8.00/LF | $18.44/LF | |

| $520 / LOT | $1,198 / LOT | |

SERVICE SADDLES (for each side of the street, labor has not been added) | ||

| PVC Pipe | DI Pipe (direct tap) | |

| $87.00 / LOT | $0 | |

LINE LOCATOR (labor has not been added) | ||

| PVC Pipe | DI Pipe | |

| $ 0.26 Per Foot | $0 | |

| $21.02/ LOT | $0 | |

CORROSION PROTECTION (assumes worst case scenario in a corrosive area) | ||

| PVC Pipe | DI Pipe | |

| $0 | V-BIO Enhanced Polyethylene Encasement $0.68/LF x 65 foot | |

| $0 | $44.20 / LOT | |

BEDDING COST COMPARISONS (assuming acceptable native soil for DI pipe) | ||

| Trench Depth: | PVC- 52-inch | DI Pipe 46-inch |

| Trench Width: | 24-inch | 24-inch |

| Select Backfill: | $22.00/ton | $0/ton |

Pricing Includes Hauling Away Unsuitable Material | ||

| PVC Pipe | DI Pipe | |

| $3.95/LF | $0 | |

| $256.75 / LOT | $0 | |

Entering these real costs into a spreadsheet we gain a clear picture of the actual cost difference versus the myth developers would have us believe. It’s important to note that your utility installation requirements may vary from this example. In that case, simply remove or adjust the numbers listed in this template.

INSTALLATION COST / LOT | PVC DR18 | DI PC 350 |

PIPE | $520.00 | $1,198.00 |

SERVICE SADDLE | $87.00 | $0 |

LINE LOCATOR | $21.12 | $0 |

CORROSION PROTECTION | $O | $44.20 |

BEDDING COST | $256.75 | $0 |

TOTAL | $884.87 | $1,242.20 |

LOT COST DIFFERENCE | $357.33 |

Calculations listed here are based on current market price at the time of this publication, November 2019.

When we calculate the actual lot cost difference of $357.33 / $200,000 housing lot, the difference comes out to 0.178 percent! Many housing subdivisions and industrial park lots are significantly higher, which would lower the lot difference even further.

For less than 2 tenths of a percent a utility can benefit from an unsurpassed design life of 100+ years, as documented by the American Waterworks Association’s Buried No Longer Study. This dramatic increase of design life allows utilities to lower their pipeline replacement from 36 to 50 percent, which is one the highest costs a utility must manage. And in many cases, enjoy lower pumping costs over the entire design life compared to DR14 PVC, as documented by the University of Michigan Life Cycle Cost Study.

On the subject of DI pipe vs PVC pipe for new development projects in their service area, Consolidated Utility District General Manager Bill Dunnill stated, “When we changed our specs in 2014, the cost to the developer was a consideration. We made some concessions in service line materials and even DI pipe wall thickness. The net increase was about $370 per lot at that time. Although not insignificant, it was minuscule in comparison to the cost of the lot, and the long-term benefit to Consolidated Utility District (CUD) Tennessee ratepayers is tremendous."

Need assistance calculating the cost for your next private subdivision installation?

McWane Ductile offers multiple services to our customers extending far beyond manufacturing Ductile iron pipe. From estimating to design, from production to installation, we take great pride in providing education and assistance to water professionals throughout the water industry. Contact your local McWane Ductile representative, today!

Check out all our digital offerings:

- More articles and videos from our Iron Strong Blog

- The McWane Pocket Engineer

- Engage with us on LinkedIn

- Follow us on Facebook

- Follow us on Twitter

McWane Ductile, Building Iron Strong Utilities for Generations.