It is pretty much a daily occurrence here at McWane Ductile for our sales staff to receive price requests on a variety of ductile iron pipe (DI pipe) products. Usually this request is for a specific project, but occasionally design engineers will also ask for “budget pricing” for future underground utility projects. This is typically a pretty simple task, but to provide the most accurate and cost-effective pricing, there are a few items that must be addressed that will ultimately determine the final cost to the customer. This article will review some of those variables that help to determine the final pricing for your DI pipe needs.

What Determines the Price of Ductile Iron Pipe?

Let’s List Some of the Variables:

- Pipe Size, or Diameter

- Pipe Class

- Pressure Class

- Special Thickness Class

- Joint Type

- Push-On

- Mechanical Joint

- Manufacturers Restrained Joint (MFRJ), or Proprietary Restraints such as TR Flex®

- Specialty (Fabricated) Pipe

- Inside Lining(s)

- Cement Lined

- Specialty Linings for Sewer/Force Main Applications

- Outside Coating(s)

- Standard Seal Coat

- Various Primers (Above Ground Exposed Applications)

- Freight (Shipping) Costs

Pipe Diameter

First and most obvious, we would need to know the pipe size or pipe diameter required for the project. Although that sounds fairly simple, we do, on occasion, have inquiries where the user does not specify a pipe size.

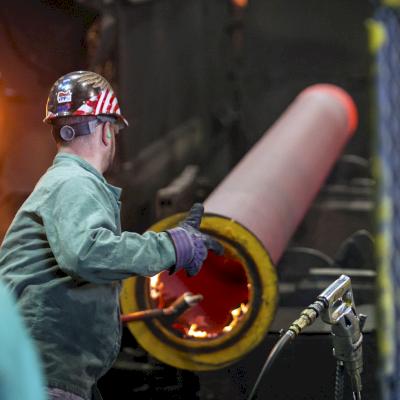

At McWane Ductile, we manufacture DI pipe in 3 to 36-inch diameters, and have the ability to fabricate pipe up to 48-inch diameter. However, just knowing the size required is not enough. As with many other products, the weight of the pipe will also factor into the cost. The weight will also correlate to the pipe class.

Pipe Class

DI pipe may be ordered as either Pressure Class (rated as Class 150 – 350 psi) or Special Thickness Class pipe (Class 50 – Class 56). Class is based on the thickness and weight of the pipe.

Many parts of the country have started using Pressure Class pipe as their standard specification for ductile iron pipe. Pressure Class pipe is thinner and uses less iron, therefore reducing the cost of the pipe. In addition, the pipe classifications are more in-line with the pressure ratings offerd in some alternate materials. Pressure Class rated DI pipe will withstand the stated working pressure while retaining all the added benefits of being made of ductile iron.

There are other regions of the country, however, that still rely on the proven history of the heavier classes, commonly referred to as Thickness Class. Job requirements such as depth of cover, trench type, soil conditions, etc. will help determine what pipe class will be best suited for a specific project. Additionally, the certain product applications, such as flanged pipe, will determine the class. The minimum wall thickness needed for flange fabrication is thickness Class 53.

Joint Types

This takes us to the various joint types you may require. The most common is a “push-on” or compression joint. McWane Ductile manufactures Tyton® Joint pipe for this application. The push-on joint costs the least of the joints produced. This joint is the most common and can be used in any area where thrust restraints are not a concern.

We also offer Mechanical Joints, manufactured restrained joints such as TR Flex® and the previously mentioned Flange (fabricated) pipe.

Mechanical Joint (MJ) pipe are much less common today and are only available in 3 – 24-inch diameters.

TR Flex® pipe is a flexible restrained joint typically used with high pressure systems or where soil conditions may be unstable. This joint uses a bolt-less system of wedge restraints to keep the pipe from pulling apart in some of the most extreme operating conditions.

There are also a good variety of “specialty” pipe joints such as River Crossing, Ball and Socket pipe, Grooved & Shouldred joint pipe, and MJ Coupled Joints. These are very project specific and are not generally items maintained in inventory.

What Type of Service Will the Ductile Iron Pipe be Used For?

The next thing we would need to consider is the type of service you would use the pipe for.

There are four main types of service:

- Potable Water (Drinking Water)

- Reclaimed (Re-use) Water

- Sanitary Sewer (Gravity Sewer and Force Mains)

- Stormwater (Drainage)

McWane Ductile can offer pipe as either cement lined or specialty lined for sewer applications. Knowing the pipe’s intended service will help determine the appropriate inside lining. The cost of DI pipe will increase with the addition of special linings.

For water services, cement mortar lining (with an interior seal coat) is the most common and usually the standard required. This is how the majority of DI pipe is stocked.

For Sanitary Sewer systems, consideration should be given to the operating conditions of the line and the types of waste it may carry. For many sewer applications, consideration should be given to using a specialty lining such as Protecto 401TM Ceramic Epoxy. McWane is an approved applicator of both Protecto 401 and CerampureTM PL 90 Ceramic Epoxy.

Pipe Coating

Now we move to the outside coating or paints that can be provided.

The standard for most DI pipe in buried applications is to provide an asphaltic based seal coat, or paint. There are other applications, particularly for exposed pipe, where a special paint may be needed.

An example would be to provide color-coded paint based on the service application:

- Blue is for potable water.

- Green is for sewer.

- Purple is for reclaimed (non-potable) water.

For these applications, McWane Ductile can provide the pipe with an approved primer coat and the finished “top coat” is usually applied in the field.

Shipping Method

Typically, the last thing to be considered is the shipping method. Most all our shipments originate as full truck load lots at a 40,000-pound minimum. We can ship less-than-truckload (LTL) lots, but this generally requires us to pro-rate the freight and add the additional shipping cost to the per-foot price of the pipe. We can also ship some specialty items, such as short spools of flange pipe, on a covered trailer or an LTL carrier.

On larger diameter pipe (pipe 24-inches and above) the total pieces per load is restricted by the safe height requirements for flatbed tuckload shipments. Therefore, we are not able to get a full 40,000 pounds on a truck. Again, the total freight for shipping would be spread out evenly to the total pieces (footage) on that load.

The main thing here is that we get as close to a full load as possible to spread out the freight cost applied on a per foot basis to each stick of pipe.

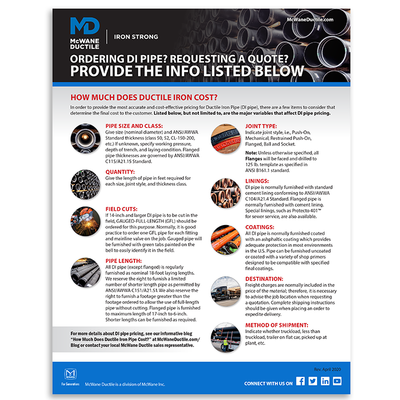

How much does Ductile Iron Pipe cost? Use this tip sheet to ensure you receive the most accurate and cost-effective pricing.

Now, Let’s Talk About Your Project and Your Needs

Again, there are many variables to account for when determining the cost of ductile pipe such as the size of the pipe, linings, coatings, joints, intended use, and more. But don’t fret. McWane Ductile is here to help with your water infrastructure pricing questions and needs.

McWane Ductile offers multiple services to our customers extending far beyond manufacturing DI pipe. From estimating to design, from production to installation, we take great pride in providing education and assistance to water professionals throughout the water industry. Contact your local McWane Ductile representative, today!

Check out all our digital offerings:

- More articles and videos from our Iron Strong Blog

- The McWane Pocket Engineer

- Engage with us on LinkedIn

- Follow us on Facebook

- Follow us on Twitter

McWane Ductile, Building Iron Strong Utilities for Generations.