CITY OF HAYWARD SEISMIC RETROFIT 12-INCH PIPELINE — CROSSING THE HAYWARD FAULT ALONG GARIN AVENUE

SITE HISTORY — THE HAYWARD FAULT LINE

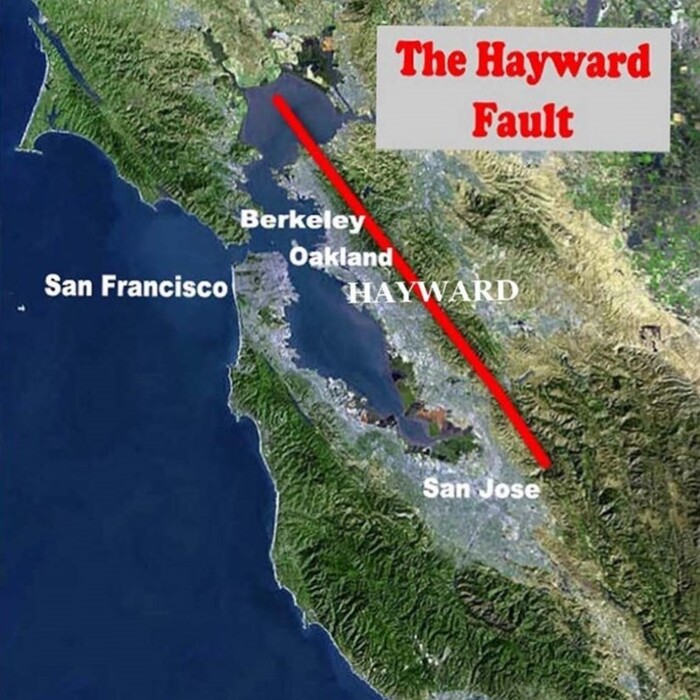

With a storied history involving faults, earthquakes and piping, the city of Hayward, California sits just across the bay from San Francisco (SF), south of Oakland. The first notable seismic event was recorded here in 1868, when an earthquake with an estimated 6.7 magnitude struck, causing significant damage and deaths. Hayward rebuilt, remaining an agricultural community in the early 20th century, then grew quickly, becoming the sixth-largest city in the SF Bay Area.

“From a municipal piping perspective, Hayward and the Bay Area saw a major Post WWII housing boom. With the war effort consuming most of the metal used in the country, Asbestos Cement (AC) pipe was developed to fill the water infrastructure need,” said Bert Weiss, City of Hayward Operations & Maintenance Manager. “As a result, many distribution systems in the region are still roughly 70% AC pipe today.”

Weiss also said, “While AC pipe might have been viewed as an excellent alternative when it was initially installed, you would be hard-pressed to find a worse-performing pipe material in earthquake-prone areas. Being crisscrossed by the San Andreas and Hayward Faults, one thing the SF Peninsula and the East Bay can count on is seismic activity.”

A wake-up call for California, came on October 17, 1989, when the 6.9 magnitude Loma Prieta Earthquake hit the SF Bay Area. The devastation was witnessed live by millions when the MLB World Series broadcast blinked off, followed by news reports of collapsed roadways on the Bay Bridge and Cypress elevated freeway, and the broken and burning buildings in San Francisco.

Hayward responded to this near-miss with a costly and extensive study of its water distribution system's vulnerability to seismic events on the fault that runs the length of the city. The Garin Fault crossing was identified as a significant risk, and the first incremental improvements were made in the early 1990s. AC pipe was “upgraded” to PVC C900 (Polyvinyl Chloride) pipe west of the Fault.

In 1995, another upgrade was made. Once the piping reached within 150 feet of the Fault, the pipe material was significantly upgraded to Ductile iron (DI) because this was the only street into or out of the development it served. At the time, these seismic improvements were considered state-of-the-art.

Unfortunately for Hayward and other water utilities in the Bay Area, replacing all piping susceptible to earthquakes isn’t feasible due to upgrade costs that require hefty rate increases for end consumers. So, the most vulnerable and critical pipelines with the highest consequence of failure have been identified for incremental improvements.

COMMENTS FROM JOHN JOHNSON, ENV SP, NACE CT, REGIONAL ENGINEER, MCWANE DUCTILE:

PROJECT CONCEPTION — SPRING 2020

This recent retrofit was conceived when Bert Weiss and I met to discuss a presentation on Seismic Resilience for Buried Pipelines. Bert mentioned a 12-inch DI push-on joint pipeline along Garin Avenue installed in 1995 with restraint gaskets was at high risk because it crossed directly over the Hayward Fault. This pipe was the sole source of potable water and fire protection for nearly 300 homes and 11 apartment buildings. His concerns were twofold:

- The Hayward Fault is one of the more dangerous faults in California. According to the US Geological Survey (USGS), as of 2014, there was nearly a 75% chance of a damaging 6.7 to 7.0 magnitude earthquake along the Fault in the next 30 years.

- Typical lateral fault movement along the Fault is 0.25 to 1 inch annually, which causes tremendous strain on the pipeline over time.

To address his concerns, I presented the McWane Ductile (MD) Earthquake Resistant Ductile Iron Pipe (ERDIP) product, with 11.5 degrees of joint deflection and 10.66 inches of axial capacity, to reduce the risk to the Garin Avenue pipeline. We agreed to complete the retrofit with the recently developed Seismic Flex Coupling™ (SFC) from McWane Ductile. The city’s field staff would perform the installation, and McWane Ductile would provide a Regional Engineer, Product Engineer, and Technical Services to consult on project design and installation.

PLANNING — FALL 2020

I then met with Bert Weiss again to evaluate site conditions. Also included was Paul Saffo, Stanford Engineering Professor, who has conducted significant research on the Hayward Fault. Paul showed aerial photography and USGS sources illustrating the Fault’s general location. We identified where the Fault line is of most concern to the existing pipeline, noted it on the 1995 As-Built plans and indicated the lateral direction the fault is moving. The USGS estimates the total width of the Fault at 40 meters (approx. ± 20 meters from the Fault centerline).

With this information, we developed a lay schedule to upgrade the system with MD SFC, which provides superior joint deflection and axial range capacity, a significant increase in resilience for future earthquakes and accommodates annual lateral movement of the Fault for decades to come.

DESIGN PHASE — SPRING 2021

A primary concern was identifying the location of existing Mechanical Joint (MJ) connections for relocation outside the Fault margins due to their limited deflection and lower seismic strain capacity than restrained joint ERDIP. We found existing isolation valves were outside the fault margins. However, a 6-inch main to a fire hydrant required relocation below the west Fault margin.

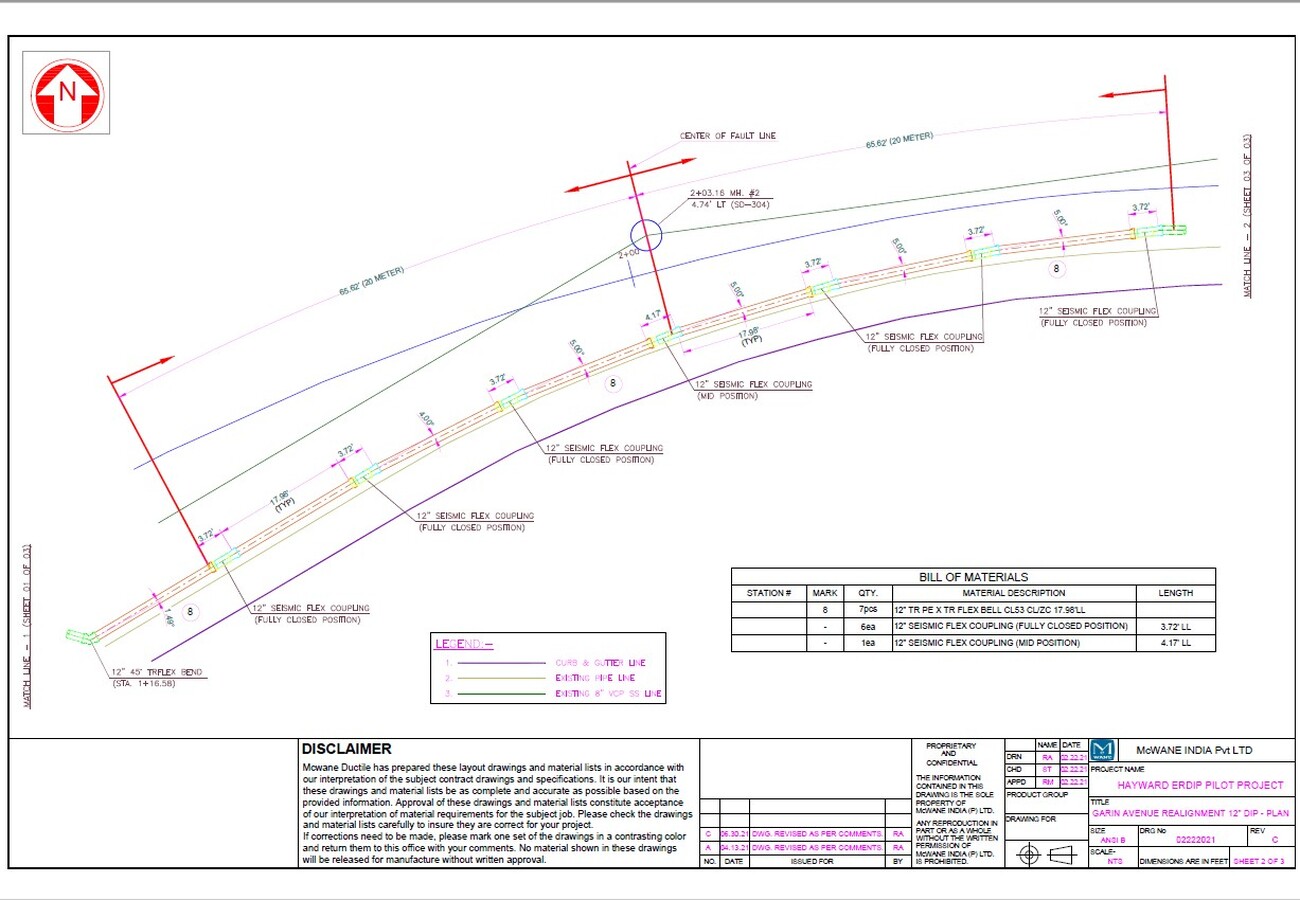

Next, a layout was needed to take advantage of the best-in-class joint deflection and axial capacity available with the McWane Ductile SFC. With fault margins of approximately 40 meters total (131 feet), a design consisting of seven Seismic Flex Couplings (SFC) at every Class 52 TR Flex® restrained joint pipe was recommended. Six SFCs would be set in the fully closed position. The seventh SFC would be set in the mid position with an additional 5.33 inches of axial expansion or compression totaling 74.31 inches of axial expansion capacity. The design was reviewed and approved by Karla Castro, P.E., City of Hayward Engineering.

Assuming an average annual movement along the fault of 0.50 inches, this layout provides 148 years of axial expansion and a considerable increase in seismic resilience where the pipeline crosses the Fault. It also significantly exceeds the performance level guideline for strain capacity in the ISO 16134 Standard, dramatically limiting the strain from fault activity affecting MJ connections above and/or below the fault margins.

Similarly, the joint deflection would be the best-in-class, providing 11.5 degrees at every joint through the Fault margin. Additionally, a 12-inch x 6-inch TR Flex Tee fitting was installed below the west margin to connect the 6-inch Class 52 TR Flex pipe to the relocated hydrant. A 6-inch SFC and TR Flex pipe was utilized for the hydrant connection to provide an additional 11.5 degrees deflection. This SFC is set in the mid position (±5.33 inches) accommodating earthquake tension or compression.

One final design improvement took advantage of the unique external load strength of Ductile iron pipe, allowing it to be buried with less cover. The Fault crossing piping has between 2.5 to 3 feet maximum cover, except where it ties back into the existing pipeline. This provides an advantage of being cheaper to install because a shallower trench takes less time to dig, uses less fuel and requires less backfill material transport.

INSTALLATION AND TESTING — FALL 2021

A City of Hayward field crew installed the mid to top section of the new ERDIP pipeline with guidance from McWane Ductile Product Engineer Jerry Regula. Here the pipeline runs from the lowest (western) SFC uphill (easterly) through the Fault margins to the east end of the retrofit connecting to the upper isolation valve. The new pipeline follows the Garin Avenue radius, installed at 2.5–3 feet of cover to the top of the pipe. It runs parallel to the existing 12- inch main, which was kept as a backup.

"The city’s field crew found the McWane Ductile ERDIP system “simple and easy to install." V-Bio® Enhanced Polyethylene Encasement was used on the retrofit, as it is a recommended laying practice listed in the ISO 16134 Standard, reducing friction on the pipeline by over 30%."

Bert weiss, city of hayward operations & maintenance manager

Hold in Place (HIP) mechanisms were utilized on installed SFCs to maintain their position through installation and pressure testing phases only. For 12- inch SFCs, these mechanisms release when forces exceed 160 psi, allowing the SFC to accommodate seismic forces. In late October 2021, the city of Hayward installed the 6-inch ERDIP section for the fire hydrant connected to the 12-inch ERDIP section. The final pressure testing and disinfection were completed on November 29, and the line was put into service.

PROJECT REVIEW – LESSONS LEARNED

The Fault location information received from the USGS was highly accurate. When the trench was dug, the fault line was within 1 foot of the location provided by the survey. The learning curve for Hayward crews was extremely short. They expressed the desire to significantly increase the amount of TR Flex pipe on future projects, as it was easy to install.

Also, we found that upsizing the V-Bio to an 18 through 20-inch product made it easier to slide over the installed SFCs. The installation was simplified further by extending the TR Flex pipeline section, below the western margin, before using 45-inch TR Flex fittings to tie back into the existing pipeline. This method avoided other utilities in the area.

"Finally, special thanks are extended to Paul Saffo, Stanford University Engineering Department, and Scott Silverthorne, Outside Sales for R&B Company. Your assistance on this project was greatly appreciated."

John johnson, regional engineer, Mcwane ductile

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.