Shallow aquifers prone to contamination, compliance with federal drinking water standards, and insufficient resources to replace aging infrastructure. These are some of the water issues that launched the creation of the Lewis & Clark Regional Water System and the construction of the Iowa Treated Water Pipeline – Segment 3.

Who is LCRWS?

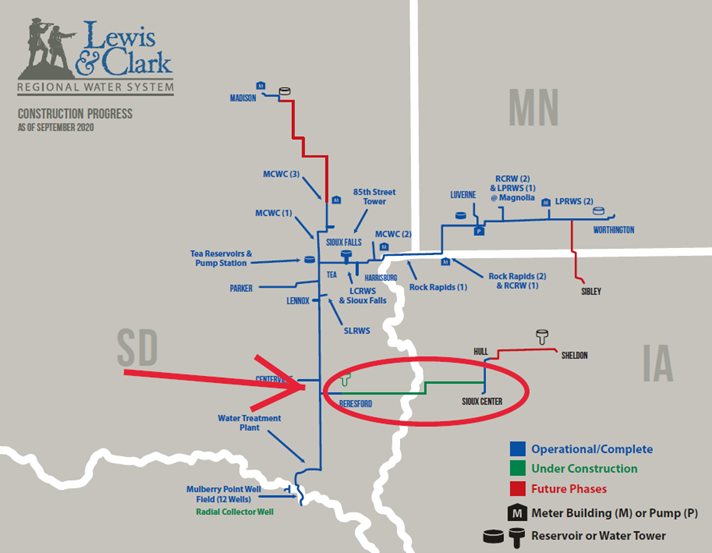

Lewis & Clark Regional Water System, Inc. LCRWS is a wholesale water provider to 20 member cities and rural water systems in 5,000 square miles in southeast South Dakota, northwest Iowa, and southwest Minnesota. When LCRWS was incorporated on January 31, 1990, one of the first orders of business was selecting a lead engineering firm. In August of 1990, Banner Associates of Brookings, SD was contracted, and they have been the lead engineering firm ever since. The original groundbreaking for the LCRWS pipeline project was held on August 21, 2003, and construction began in earnest in 2004. When completed, the LCRWS will provide a source of quality, reliable drinking water to over 300,000 people through 337 miles of pipeline.

What Does This Segment Consist Of?

The roughly 12.6 miles of Iowa Segment 3 runs from outside Beresford, SD, to Sioux Center, IA. This section has some of the lowest elevations in the system (including the Big Sioux River crossing) and thus some of the highest pressures. Due to these higher pressures and extreme conditions, PVC pipe would not be used, and a stronger, more durable material was required.

Who Was Involved in the Pipeline Build?

In June 2019, before bidding on the project, a meeting was held with Banner Associate’s engineers Scott Vander Meulen and Dennis Odens and McWane Ductile Product Engineer Jerry "JR" Regula, Sales Representative Robin Hazlett, and National Account Manager, Jeff Henderson. The team reviewed and updated the specs relative to Ductile iron pipe.

In addition to the pressure requirements, the specifications were very demanding to account for the highly corrosive soils in the area. The DI pipe specs required a zinc-coating on the pipe and a V-Bio® Enhanced Polyethylene Encasement to be installed with an impressed current cathodic protection system.

Carstensen Contracting, Inc. (CCI) of Dell Rapids, SD, who had already installed six previous sections of the LCRWS, was awarded the $19 million contract for Iowa Segment 3. With a substantial completion deadline of December 2021, Carstensen Contracting chose to work with McWane Ductile

What Were Some of the Steps Involved?

As outlined in the specs, there was an option for the engineers/owners to visit the foundry to inspect the manufacturing process. As dates were finalized for the foundry visit, the Covid19 pandemic struck. The pandemic severely hampered travel and eliminated foundry tours. To satisfy this condition, the production team at McWane Ductile provided photos of the pipeline production. Detailed pictures were labeled and sent to Banner Associates for review and documentation.

Key players at McWane Ductile and Carstensen Contracting held conference calls to coordinate the timing and scheduling of deliveries. Eventually, these calls included vital people from the trucking company as well.

TR Flex® fittings and custom TR Flex lengths were fabricated and coated to complete the restraint requirements and connect the air valve and blow-off assemblies and the isolation valve vaults and flushing assemblies. This fabrication process of these specials was also documented where necessary.

McWane Technical Services Specialist, Cory Humphreys, provided a detailed line drawing plan and profiles to ensure everything was installed as designed and to provide accurate as-builts upon completion.

Deliveries began in July of 2020. McWane Ductile was on site for the first arrivals to inspect the pipe deliveries and fine-tune any dunnage changes to protect pipe during shipment. Amy Harris, CSR, provided weekly delivery updates and pipe certifications on daily shipments and coordinated the deliveries with the field people at CCI.

Kick-Off Training, Construction, and Final Completion

Before the first stick of pipe was put in the ground, a section of the specifications required a “kick-off training” with every entity involved in the project. Key people from every company involved were all on hand for the day. Corrosion Consultant Bill Spickelmire of Rustnot Corrosion Control Services explained and reviewed the cathodic installation procedures. Jerry Regula with McWane Ductile provided instruction on handling and installation of Ductile iron pipe and V-Bio. Pipe installation started immediately after the kick-off training.

The spec also required that McWane Ductile provide a factory-certified representative to be on-site for the first three days or installation of the first 2,000 feet of pipe, and then, for three days per month, for the duration of the installation. Jerry Regula made the trip to South Dakota every month during the pipeline build, observing and reporting to Banner Associates each time.

With each shipment, McWane Ductile provided all the required certifications and manufacturing records. The project continued through the summer and fall of 2020 and resumed in the spring of 2021. Pipe, fittings, and custom fabricated pieces continued shipping as construction progressed. The material was always delivered well before it was installed to ensure the crews were never delayed.

On September 14, 2021, the last piece of pipe was installed. This final piece completed the connection between Iowa Segment 2, near Sioux City, IA, and South Dakota Segment 12, near Beresford, SD. A ceremony was held with Lewis & Clark management, directors, Banner Associates, CCI personnel, McWane Ductile, and dignitaries from local cities that will benefit from this water source. Everyone present signed the last pipe before it was lowered into the ground and connected to the system.

A Few Words of Thanks

This project was successful due to excellent coordination and communication between all the parties involved. Lewis & Clark, Executive Director Troy Larson stated, "The Lewis & Clark Regional Water System greatly appreciates the partnership with McWane Ductile. Everyone has been great to work with and has shown the utmost professionalism. They have worked hard to deliver a top-quality product on time. We could not be more pleased with the results."

Banner Associates was great to work with. Any issues that arose were handled quickly and fairly, so work progressed on or ahead of schedule. I look forward to the opportunity to work with Banner on more projects in the future. Engineers Scott Vander Meulen and Kevin Kuebler, the on-site inspector, are great examples of everyone working together to achieve a goal. Scott Vander Meulen said, "Thank you, McWane Ductile! McWane has provided a great product and exceptional service for the Lewis & Clark Iowa 3 project!"

Kevin Kuebler had this to say, “As the Resident Project Representative for the Lewis & Clark Regional Water System Iowa 3 project, my experience with the McWane Ductile Iron team was great. I appreciate the on-site visits from Jerry Regula and Jeff Henderson. Any technical and installation questions we had during construction were quickly answered. They provided a great product, and I particularly like the ease of the TR Flex restrained joint piping and fittings. Thank You, McWane Ductile!"

As for Carstensen Contracting Inc. (CCi), I know I speak for everyone involved in this project at McWane, conveying tremendous gratitude to CCI and how they do business. Ricky Carstensen had this to say about working with McWane Ductile, "Jeff, (the McWane) team has been top-notch to work with. From the plant personnel to yourself, JR and get’er done Dodge. We will be doing more work together. Thanks for the great product and the friendship!"

Augie Luna, Construction Manager at CCI, had this to say, “CCI has worked with numerous reputable vendors that have a good sales pitch, but one thing that stood out for the McWane team is everything they said, they stood behind it and fulfilled."

For me, I must give a huge thanks to everyone at McWane Ductile, Ohio. Every team member involved worked hard to make this job a success. Everyone exceeded what was expected, and I am very pleased to be a part of this company and proud to be part of this team.

Need Assistance with Your Waterworks Project?

McWane Ductile appreciates the opportunity to highlight this project. If you have any questions regarding your water or wastewater infrastructure project, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.