As the name suggests, Long-Span pipe can extend over distances with fewer supports than conventional Ductile iron pipe (DI pipe). In standard 18-foot lengths of DI pipe, a minimum of one support is required within 2-feet of the Bell for each length of pipe. When using Long-Span pipe, distances of 27-foot up to 45-foot and longer can be achieved with support only at the Bell ends.

What Is Long-Span Pipe and How Does It Work?

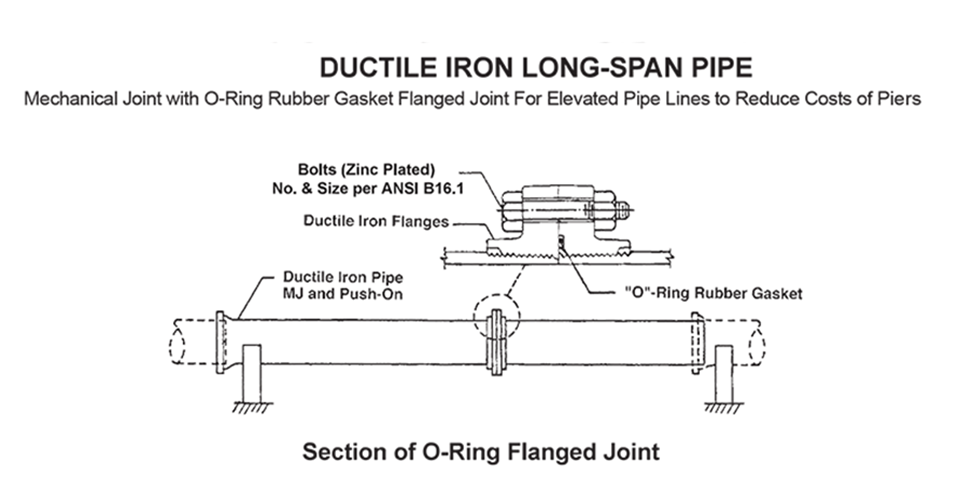

Ductile Long-Span pipe is comprised of multiple-length pipe segments utilizing a specially designed Flange Joint connection with an O-ring rubber seal made of Nitrile (Buna-N) material for minimizing the number of piers or hangers required in elevated lines such as pipe on supports and other crossings.

For key considerations when using DI pipe for bridge crossings, see this helpful Iron Strong blog by my colleague, Jerry Regula. For additional information on installing pipe on supports, please refer to Ductile Iron Pipe Research Association (DIPRA) ’s publication on this topic, “Design of Ductile Iron Pipe on Supports.”

Span Lengths (and Pipe Class) by Diameter Are Offered As:

- 6-inch, 8-inch, and 10-inch (Class 54) can achieve spans of up to 27 feet.

- 12-inch, 14-inch, 16-inch (Class 54) can achieve spans of up to 36 feet.

- 18-inch (Class 54) can achieve spans of up to 36 feet.

- 18-inch (Class 56) can achieve spans of up to 45 feet.

- 20-inch (Class 55) can achieve spans of up to 36 feet.

- 20-inch (Class 56) can achieve spans of up to 45 feet.

- 24-inch (Class 56) can achieve spans of up to 45 feet.

- 30-inch (Class 55) can achieve spans of up to 45 feet.

Available Configurations Are as Follows

Long-Span can be provided in a variety of lengths depending on the diameter of the pipe. Details for recommended designs are as follows:

- 27- foot sections are 18-foot lengths of Bell and Flange, plus 9-foot lengths of Flange and Plain End.

- 36-foot sections are 18-foot lengths of Bell and Flange, and 18-foot lengths of Flange and Plain End.

- 45-foot sections are 18-foot lengths of Bell and Flange, 17-foot Flange and Flange, and 10-foot Flange and Plain End pieces. Installation requires support immediately behind each Bell, with allowance for expansion and contraction. Length tolerance of each unit is plus or minus ¼ inch.

Installation Techniques Follow A Simple Process

Long-Span pipe are shipped un-assembled with the necessary accessories packaged separately. Pipe conforms to ANSI A21.51. Flanges are 70-50-05 Ductile iron using zinc plated bolts of the same size and number as ANSI B16.1 125-pound flanges. For information on Ductile iron versus steel flanges, see this informative Iron Strong blog by my colleague, Scott Frank.

- Following the off-loading of your DI pipe, arrange sections in an area near the proposed crossing.

- Connect each length of pipe utilizing provided accessories (O-ring, nuts, and bolts).

- Be certain bolts are tightened in a star-type pattern and per the manufacturer's recommended torque requirements (Use a torque wrench to verify).

- Once desired pipe sections are assembled to cover the crossing, attach lifting straps/chains in an area of proximity to the supporting flanged bells and lift the pipe into place.

McWane Ductile can be a valuable resource in assessing appropriate applications for Long-Span pipe, as well as alternative joint configurations based on field conditions. In addition, we can assist in providing engineered drawings for project submittal, as well as detailing the best pipe configuration for your unique application.

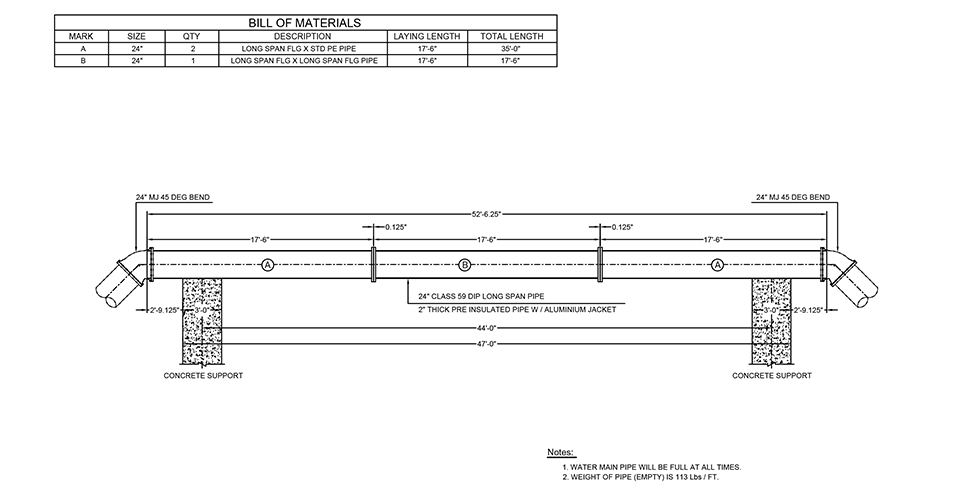

The following is a sample of an engineered drawing illustrating a 24-inch pipe on a Supports Stream Crossing utilizing the following material:

1ea. - Long-Span Flanged X Long Span Flanged Pipe, 17' 6" (B Section)

2 ea. - Long Span Flanged X Plain End Pipe (A Sections), 17' 6"

By combining the sections in this way, we are abe to acheive a 45-foot crossing utilizing only two supports located at each end of the crossing.

Need Assistance with Your Waterworks Project?

As always, if you have any questions or require additional information, please feel free to contact your local McWane Ductile representative. We have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design, to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings