When it comes to restraining a water line, what comes to mind? Thrust blocks? Sure Stop 350® Gaskets? (locking gasket), TufGrip™ (wedge-action retainer gland), or maybe the standard default choice, TR Flex®? (Ductile iron restrained joint pipe). There is another option that might not regularly come to mind. It is known as Mechanical Joint Lock Joint or MJLJ for short. We will look at how the joint works, how it is installed, and locations where the MJLJ may be preferred.

How does the Mechanical Joint Lock Joint Work?

Some people think that Mechanical joint pipe is a restrained joint pipe. However, standard Mechanical joint pipe is not restrained by design. The gasket, as compressed by the tightened gland assembly, does create a watertight seal on the joint to a rating of 350-psi, but will not prevent longitudinal joint separation beyond 50-psi (if unburied) without assistance from other mechanisms. It becomes restrained by use of a retainer gland or system being substituted for the standard gland, or by properly designed and cured thrust blocks being in-place.

Some municipalities do not allow retainer glands, so to connect securely to MJ type appurtenances (Ex: MJ tees, valves, hydrants, etc.), you will need to involve a fabricated mechanical joint restraining-spigot. This joint is made of such a fabricated spigot (weld-on ring applied) attached, and thereby restrained to its companion and otherwise-standard MJ bell.

You can see in the diagram above that this specialized joint uses two glands, one that is located behind the welded-on locking ring during fabrication, which provides the joint restraint needed, and one that will be installed by the installer on the end of the pipe during joint assembly and provides for the watertight seal by compressing the lubricated gasket in its bell cavity.

What are some considerations when using the MJLJ?

This joint does require some planning due to the pipe needing to be fabricated in the shop prior to being shipped to the jobsite, and often at various lengths to accommodate proper stationing of the fittings or other connections. It is common for inline pipe joints to be restrained via fabricated restrained joint systems such as TR Flex, with MJLJ being used for lasting surety of the mechanical joints connections of the pipeline. The combinations of joints, all rated to 350-psi, are left completely to the discretion and desires of the specifying or design Authority.

To fabricate this joint, we start with a standard plain end of pipe, cut to appropriate laying length as needed. After achieving the correct length, the rear gland in the joint assembly is placed onto the pipe barrel to a location beyond where the weld ring will be affixed. Next, the locking ring is welded into place.

To complete the pipe fabrication, we verify the lining quality and apply the appropriate inside and outside coating as specified for each project, typically just water-based NSF-61 certified asphaltic sealcoat. A proper supply of longer than standard Corten T-head bolts and nuts are shipped along with the pipe to facilitate both glands at once and are provided as part of this joint's use.

How is the MJLJ assembled?

Now to move to the installation, see assembly instructions below OR click this link to download a handy tipsheet with the MJLJ Assembly Instructions.

Assembly Instructions:

- Before starting the project or any assemblies make sure you gather all the appropriate Personal Protection Equipment (PPE), all tools and materials needed such as a wire brush, paint brush, pipe lube, clean rags, wrenches, and perhaps a bucket of clean water for cleaning away debris of shipment or site storage from the pipe ends.

- Start joint assembly by cleaning the bell socket and spigot end. Be sure to remove any dirt, ice, or foreign matter from any jointing surfaces.

- Place the gland on the plain end with the lip extension toward the plain end.

- Lubricate all gasket surfaces (with pipe manufacturer approved lube only), preferably directly upon the gasket itself or the spigot OD and gasket seat cavity each as an alternate method of ensuring NO FRICTION in the joint. Place the gasket on the plain end with the narrow edge of the gasket facing the plain end.

- Insert the plain end of the pipe into the MJ bell until it rests against the back of the bell, essentially creating a continuous internal barrel.

- Press the gasket into the bell recess. Push the gland toward the socket and center it around the pipe with the gland lip against the gasket

- Slide the second gland up the pipe away from the spigot end to allow enough room for the joint assembly with the first gland.

- Insert the T-head bolt through the bell bolt hole and into the 1st Attach 1st nut.

- Snug the bolt by hand.

- Repeat the process with all remaining bolts.

- It is important always to maintain the same distance between the gland and the bell face for a proper seal. Do NOT tighten the bolts in a simple circular fashion.

- After all, bolts are assembled on the first gland, and all are tightened by hand, then use a torque wrench. Alternate side to side and top to bottom to achieve equal distance and torque.

- Slide the second gland onto the bolts and attach the second set of nuts. If joint deflection is needed, apply before tightening the second nuts. Tighten the nut on the second gland by hand. Then you will want to use a torque wrench to tighten these nuts to 20-foot-pounds of torque.

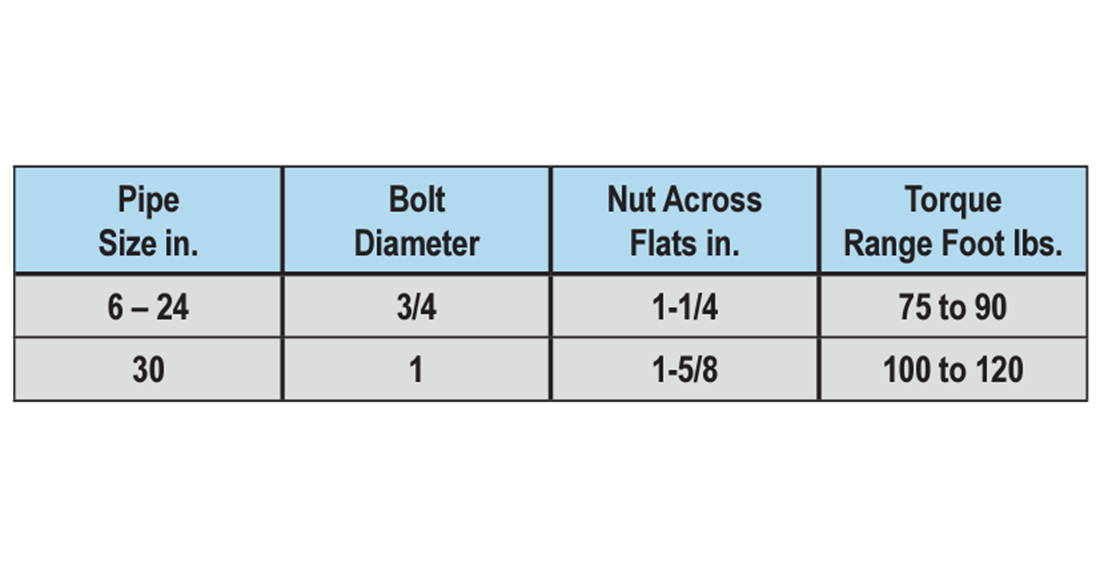

Note: Achieving the recommended bolt torque, particularly with large diameter pipe, may require repeating step 12 up to five times or more. Recommended bolt torque ranges are as follows:

We're Here to Assist with Job Start-Up Instruction

Job start-ups with McWane Ductile cover a broad area of topics. Examples may include: Joint assembly and deflections, unloading and storage of accessories, and much more. We provide this as an added service with our pipe and encourage the contractor, inspectors, and owner to attend. Job Start-up meetings provide excellent opportunities to provide training for crews and answer questions that may be project specific.

Mechanical Joint Lock Joint or MJLJ is just one of various restraint options provided by McWane Ductile that can be incorporated to restraint for any Mechanical Joint (MJ). We recommend you visit McWane Ductile.com, contact your local Sales Representative, or join us at trade shows across the country. Let’s work together building Iron Strong Utilities!