It’s a great day on the job site, and your crew is running hard—you're making up for lost time, possibly due to weather delays. You're expecting your next load of Ductile iron pipe (DI pipe) any minute, and your goal is to unload your pipe as safely and quickly as possible. Before you let the truck take off, you need to understand and follow these guidelines before receiving your pipe.

Safety First

- Make sure you unload your DI pipe in a safe location, free from traffic hazards.

- Be sure to wear the appropriate PPE.

- Keep in mind, the truck and trailer need ample room to maneuver.

- Carefully inspect any bands or straps securing the pipe, as they may have come loose during transit.

Establish Your Unloading Area

- The unloading area should be level to help maintain the stability of the truck and trailer. The ground should be free of potholes and debris.

- Look up and look around. The unloading area should be clear of overhead electric lines. Coming into contact with a power line can be dangerous – even deadly.

- The unloading area should be clear of other traffic – vehicles or foot. Pedestrians, truck drivers, or other employees not involved in the loading/ unloading process should stay away from the area.

- The unloading area should have enough lighting for early morning or evening loading or unloading.

- Be sure you have the proper equipment on-hand to handle the weight of the pipe and to safely unload the pipe. See this helpful Iron Strong Blog by my colleague, Gary Gula on the importance of knowing the weight of DI pipe.

What Do You Check for When the Ductile Iron Pipe Arrives?

-

Verify Your Quantities.

- This can be accomplished by counting your sticks of pipe while they are on the truck, making sure they match the quantities on your BOL (Bill of Lading).

- Many times, trucks will have more than one destination. To ensure that you are getting the pipe you ordered, it is essential to count the pipe and examine the product sticker.

-

How Do You Identify Your Pipe?

It is important to confirm you have the correct product. All McWane Ductile pipe comes with an identification sticker applied to each stick of pipe to help you identify what pipe you have.

Typically, you can find the identification sticker near the bell of the pipe. The label will provide the following information:

- Pipe Size (Diameter),

- Pipe Class

- Joint Type

- Lining(s)

- Coating

- Cast Date

You can learn more by visiting Ductile Iron Pipe Markings: What Do They Mean? by my colleague Jeff Houser

Separating Your Ductile Iron Pipe

When pipe 14-in and larger is shipped, your load of DI pipe will typically come with “gauged pipe." You will want to create a separate stack for you gauged pipe, as they will be used for your field cuts. To learn more about the importance of gauged pipe or how to properly cut DI pipe in the field, check out these helpful blogs:

- How To Cut Ductile Iron Pipe to Length by Jason Barnes

- Why Is It Important to Know the OD/ID of Ductile Iron Pipe? by Dusty Henderson

Where Are Your Gaskets?

Be sure to confirm your gasket count.

- You can identify your gaskets and confirm the quantity of gaskets by checking the bags or crate that they arrive in. The driver may place gaskets in the truck cab, protecting them from the elements or theft. Be sure to confirm with your driver before they leave.

- Once you have your gaskets, be sure to store them out of the elements, Follow our tips in this helpful blog on “Proper Gasket Storage and Care.”

Where Is Your Pipe Lube?

Each load of pipe will come with pipe lube. Pipe lube is typically stored in large bags. These bags can often be found in the crates with your gaskets.

Pro Tip: You should always use the lube supplied with the pipe. Extra lube is available upon request. Contact your local McWane Sales Representative for assistance.

What is a Bill of Lading (BOL)?

- BOL in the freight shipping industry stands for the Bill of Lading. This document is required and serves as a receipt of freight services or a contract between the carrier and the freight shipper. The BOL also serves as POD (Proof of Delivery). It provides all the necessary details to process and invoice a shipment correctly such as:

- The date of delivery

- The number of units

- The freight classification

- The weight, etc.

The BOL is created and then presented to the carrier at pickup. The shipper retains a copy of the BOL for their records. Check out this informative Iron Strong Blog on How Much Ductile Iron Can Ship on One Truck by Martin Rodriguez.

Check for Damage

Although it is a rare, pipe can become damaged during loading and transporting. You should always:

- Examine the cargo with the driver: Thoroughly inspect each piece delivered to for visible damage. The driver should walk through this process with you. That way, they are aware of any issues or damage you note.

- If the freight is damaged: If you see visible damage, photograph the damaged goods, and make a detailed note of it on the Proof of Delivery.

- Check Delivery Documentation (packing list, certifications, etc.). Make sure you have the correct paperwork. Again, trucks often make multiple deliveries. Having the proper paperwork will assist in any questions or concerns that you may have.

When to Sign the BOL

If you are the person designated to receive the shipment, you must thoroughly inspect it before signing the BOL, as it serves as Proof of Delivery. You must confirm the following:

- The shipment was intended for you

- The shipment's entirety arrived,

- The shipment arrived undamaged.

If you sign it and later find damage, you will have difficulty proving that the damage occurred during transport.

A Bill of Lading is not just a receipt of delivery, but a receipt that the goods have been delivered safely. Any damage claim procedures start with the BOL. So, if you find that you are missing product or don’t have the correct products, be sure to mark your BOL accordingly and have the driver sign as a witness. Once you sign the BOL, the product is yours.

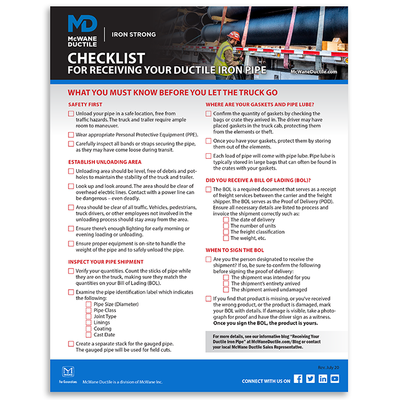

We’re Here to Assist

By following the recommended guidelines above, you can ensure that your Ductile iron pipe from McWane Ductile is safely received as you intended ─ with proper quantity, class, type, size, linings/coatings, and all necessary accessories. We encourage you to download our handy Checklist for Receiving Your DI Pipe by clicking the download button below. If you have any questions regarding this blog or anything Ductile iron pipe related, please feel free to reach out to your local McWane Ductile Sales Representative.

Before you let that truck full of Ductile iron pipe go, be sure to follow the guidelines on this free and handy checklist!

We are here to assist with team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.