Any Ductile iron pipe installation project aims to build a safe, long-lasting, and leak-free pipeline. Occasionally, you may seek resources to ensure you are installing pipe correctly. That’s where McWane Ductile comes into play. Along with our Learning Center, chock full of informative blogs, installation guides, and tip sheets, we have recently created some new videos detailing some best practices. Check out these detailed step-by-step installation videos below to help boost the productivity of your entire crew!

WHAT IS TYTON JOINT® PIPE?

Tyton Joint® pipe is manufactured by McWane Ductile in 3-inch to 36-inch diameters in special “Thickness Class” and standard “Pressure Class” selections. As the most widely used gasket system for pipe in North America and worldwide, the Tyton Joint provides 5 degrees of deflection, allowing easy pipeline routing around obstacles with minimal fittings.

Tyton Joint pipe is offered with various lining options, including single and double-thickness cement, Protecto 401,™ or bare. Exterior coating options include standard asphaltic paint, zinc, or bare. Tyton Joints are known to be easy to install, but there's more to it than just pushing it together. See the video and Tip Sheet below for more details.

WHAT IS TR FLEX® RESTRAINED JOINT PIPE?

Simply put, TR Flex® Restrained Joint pipe is the most widely accepted and installed integrally-cast restraint joint system in the Ductile iron pipe industry. Proven as a versatile and easy-to-use item, this joint is flexible, sure, and watertight to and beyond its 350-psi pressure rating while preventing longitudinal separation of the joints whether installed above or below ground. TR Flex® utilizes the Tyton Joint® gasket for a watertight seal along with a factory-adapted spigot and extended bell casting to provide positive and permanent joint restraint. This video will show you how to lock it in.

WHAT ARE TR FLEX® FITTINGS?

McWane Ductile’s TR Flex® Restrained Joint Ductile Iron Pipe and Fittings are manufactured in 4-inch through 36-inch sizes. The pipe and fittings are boltless, allowing quick, simple installation without special wrenches or tools, and utilize a factory-welded spigot bead and internal locking segments in a special bell to provide positive restraint while maintaining joint flexibility.

The fittings are rated for 350 psi up through 24-inch and rated for 250 psi in 30-inch and 36-inch sizes. These fittings employ the same joint configuration and locking segments as TR Flex pipe joints, thereby providing equal assurance of lasting performance against both internal and external loads of all kinds. McWane Ductile’s TR Flex fittings are currently available as non-domestic only.

When your pipeline takes a turn, can you handle the change in direction? Come-Along and learn the steps to install TR Flex Fittings.

WHAT IS MECHANICAL JOINT PIPE?

The "original" modern pipe joint, circa 1925; the Mechanical Joint remains in use primarily to connect fittings, valves, and similar appurtenances to a pipeline. The nuts, bolts, and glands featured in the joint provide a permanent watertight seal to 350 psi and more through a “stuffing box” compression of the gasket into its counterpart triangular recess of the joint. There's no reason to be intimidated by your Mechanical Joint Pipe installation. Let this video be your guide.

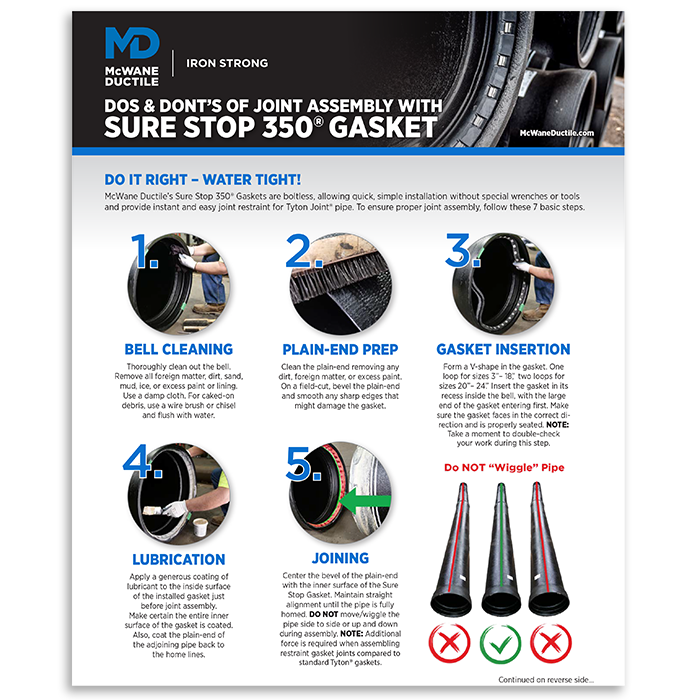

WHAT ARE SURE STOP 350® GASKETS?

Sure Stop 350® Gaskets for Tyton Joint from McWane Ductile are available from 3-inch through 24-inch to provide instant and easy joint restraint for Tyton Joint pipe. Sure Stop 350 Gaskets are rated for 350 psi working pressure with a 2:1 safety factor, allowing up to a 5-degree deflection at each joint.

Sure Stop 350 Gaskets are boltless, allowing quick, simple installation without special wrenches or tools, and are Underwriters Lab (UL) listed and Factory Mutual (FM) approved. McWane Ductile’s Sure Stop 350 Gaskets can be furnished with various gasket compounds, including the standard SBR, Neoprene, EPDM, and Nitrile. Proper Sure Stop® Gasket assembly is critical to avoiding displaced or rolled gaskets. Learn how with this video and Tip Sheet.

Do it right – watertight, when installing Sure Stop 350™ Gaskets. Use our free and handy tip sheet to ensure proper joint assembly.

DOWNLOAD NOW

WHAT IS A FEELER GAUGE?

A feeler gauge is typically a thin, flexible metal blade/bar that may be inserted in the annular space between the bell ID and spigot OD at sufficient intervals around the joint. This ensures that the leading edge of the gasket is in approximately the same position or depth around the entire installed joint.

This depth will vary slightly depending on the size of the pipe being installed. The end of the feeler gauge will extend further into the joint in the location where the gasket has been displaced. Little to no effort or force is used when inserting the feeler gauge into the joint.

Items used as a feeler gauge include small banding pieces, a paperclip, a small allen wrench, etc. McWane Ductile has taken the initiative to develop this useful tool, complete with a handle that makes it easy to use, fits in a pocket or safety vest, and is easy to keep track of on a job site. Using a Feeler Gauge to confirm a gasket is seated correctly can save you time, money, and stress before hydrostatic testing your pipeline. Learn how in the video below.

Need Assistance with Your Waterworks Project?

McWane Ductile strives to be the go-to resource for everything Ductile iron pipe related. The videos and tip sheets in this #IronStrong Blog are just a small sampling of our many resources. If you have any questions regarding your water or wastewater infrastructure project, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we provide education and assistance to water professionals throughout the water and wastewater industry.