During a recent business trip, I noticed water being used randomly to combat the summer heat at various locations, construction sites, local sporting and recreational activities, fire safety, and public welfare. As I observed these activities, I wondered if the public understands how water gets from nature to human use and consumption.

Most Americans can easily access a disinfected drinking water supply at home and the workplace. However, many do not know how public water treatment works before it reaches their glass. This year marks the 50th anniversary of the Safe Drinking Water Act, a federal law enacted in 1974 to protect drinking water quality in the United States. This act is crucial in ensuring that our water is safe and clean. To celebrate this milestone, I'm sharing this #IronStrong Blog, which explains water sources in general terms, the treatment of water, the public water distribution system, and the role Ductile iron pipe plays.

Water, Water, Everywhere?

According to the U.S. Environmental Protection Agency (EPA), Americans consume more than 1 billion glasses of drinking water (also known as potable water) daily.1 While adults drink more water than ever before, we often take this for granted. Water makes up 60% of our bodies, so ensuring our society has access to clean water is extremely important to our body's health and performance.

Roughly 70% of the earth's surface is covered in water. Even though water seems to be everywhere, not all of it is suitable for use as drinking water. Of all the water on earth, approximately 3% is fresh, with much of it frozen or underground. Less than 1% of the water on earth can be used as potable water, highlighting the scarcity of this vital resource. Today, more than 780 million people worldwide lack access to clean drinking water, according to the U.S. Centers for Disease Control and Prevention (CDC)2. Water is a vital commodity and should not be taken for granted. Understanding how we get water from nature to the facet will help us appreciate this valuable asset even more.

Where Does the Water Come From?

Water Sources

The first part of understanding how water gets from nature to the faucet starts with the type of water source available. Water is typically supplied to your home from either a public water supply or a private well. Source water refers to sources or bodies of water (such as rivers, streams, lakes, reservoirs, springs, and groundwater) that provide water to public drinking water supplies and private wells. According to the CDC, most U.S. tap water sources are derived from surface or groundwater3. The following are some essential distinctions between surface and groundwater.

Surface Water

- Surface water originates from above ground, including streams, rivers, lakes, wetlands, reservoirs, and creeks.

- Comes from rain and snow

- Supplies approximately 64% of public water systems

- Accumulates in rivers, streams, and lakes

- Is piped and pumped to water treatment centers

Groundwater

- Groundwater is underground water in the cracks and spaces in soil, sand, and rock.

- Comes from rain and snow

- Supplies approximately 36% of public water systems

- Seeps into the ground and is then stored in natural aquifers

- Must be accessed at a spring or pumped out of the ground via a well

How is Water from Various Sources Treated?

One of the most common ways water is supplied to communities is for the water utility to pump water from a water source (river, reservoir, or well) into a water treatment plant. The treated water is then pumped into a water tower, which often sits on high points within an area. Using gravity, the water flows from the water tower through pipes to residences or businesses. In many rural regions, public water-supply systems do not exist; homeowners may utilize groundwater wells but often still need to fill up a tank that supplies the water used in their homes.

Local water suppliers using water from local surface water (rivers, lakes, or reservoirs) must use a treatment process to remove particles, organic matter (such as leaves and sticks), and contaminants. The utility supplier adds chemicals called coagulants that help the organics to form into clumps and settle to the bottom of the tanks that store the water. Once the settlement occurs, the water is filtered to remove microscopic germs. The most common drinking water treatment is disinfection. Most water suppliers add chlorine or other disinfectants to kill bacteria and other germs. They may use different treatments to make the water clean and safe, depending on the quality of their source.

Water suppliers that use water from an underground source use a different process. Groundwater is naturally filtered as it passes through the earth into underground reservoirs called aquifers. Typically, water from wells contains less organic material than rivers and reservoirs.

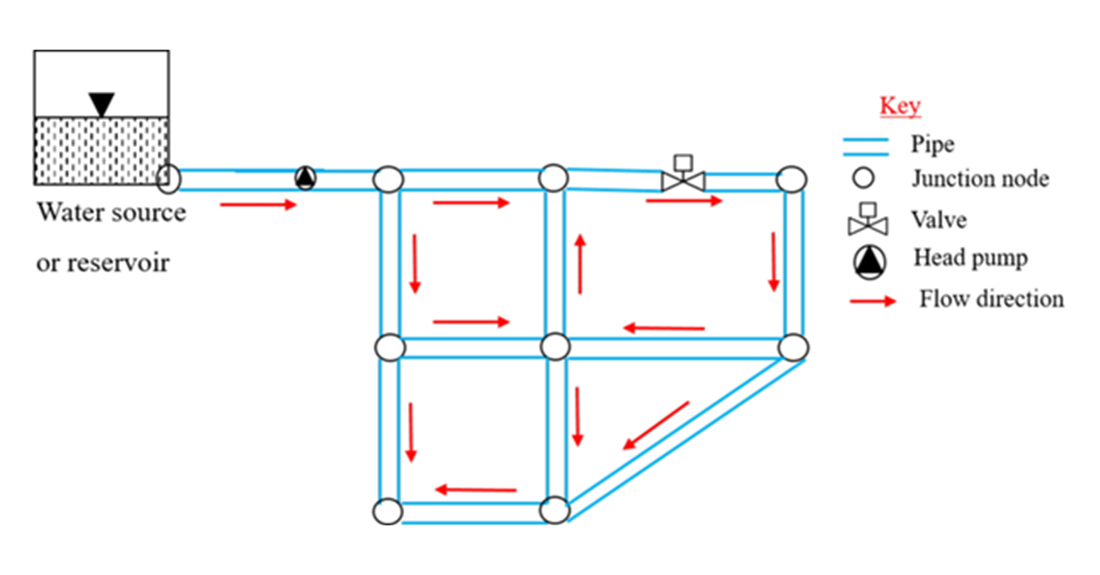

After drinking water is treated and meets the U.S. Environmental Protection Agency’s Safe Drinking Water Standards,4 it's transported to storage facilities where homes and businesses can access safe, clean drinking water straight from their taps. The EPA reports that American water distribution systems span nearly 1 million miles and deliver water to approximately 300 million people.1 Distribution systems are primarily underground and include:

- Pipes

- Control valves

- Pumps

- Meters

- Storage tanks

- Hydrants

What Pipe Characteristics Affect Water Systems?

Distribution systems must provide an adequate amount of water with sufficient pressure. Pumping water to the top of a water tower or tank in a high location creates water pressure. When the water is released from a water tank at a higher elevation, it creates a force called "head"; this head (difference in elevation from water tank to end user) moves the water through the water transmission mains and distribution pipes.

Residential water pressure is usually between 45 and 80 pounds per square inch (psi). The pipes that transport water can be made of several different materials. The type of pipe material used within a water system is extremely important because the material type can affect the operation, maintenance, performance, and longevity of a pipeline.

What Difference Does Ductile Iron Pipe Make in Water Infrastructure?

Service Life

Ductile iron pipe (DI pipe) is an essential pipeline material used extensively within a water utility's pressurized pipe system because of its unique attributes. The first reason is service life. The longer a pipeline lasts, the better it is for the utility and its customers. Unlike other materials, Ductile iron has a high tensile strength (60,000 psi) and is not subject to weakness over time.

Some other pipe materials suffer from what is known as "creep." Creep in a pipeline is "a type of deformation that occurs when a material is subjected to constant stress or high temperatures over a long period." This loss of strength or deformation in other pipeline materials is often accelerated by changes in temperature, pressure, and other performance factors found in pressurized piping systems. Ductile Iron pipe is not affected by “creep” or other changes because of its high tensile strength.

The Ductile iron pipe industry promotes a service life of 100 years, and often, the service life well exceeds 100 years. For more information on this topic, see this blog by my colleague, Roy Mundy, Buried No Longer – Confronting America’s Water Infrastructure Challenge. The pipe you install today will be the pipe you rely on for generations.

Lifecycle Cost

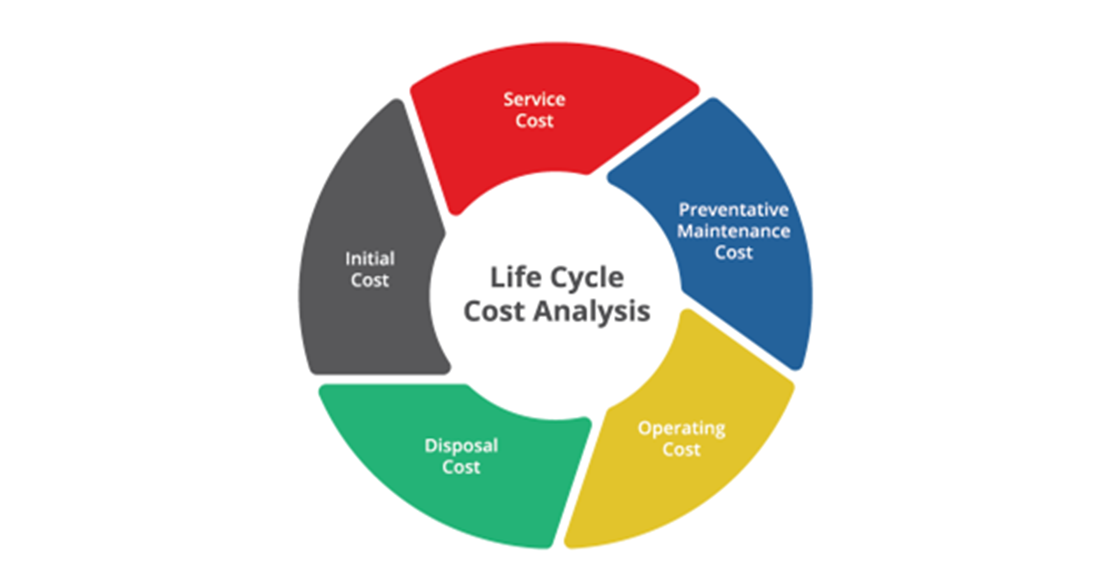

As we now know, today's material cost can often be insignificant compared to the total cost of ownership over its life. We consider this lifecycle cost when purchasing everything from cars, houses, appliances, and electronics.

Lifecycle Cost Analysis is defined as “assessing the total cost of ownership over the asset's life, taking into account all costs of owning, maintaining, operating, and the end of life of the product." Lifecycle cost is one of the most significant advantages of Ductile iron pipes. Because of its long service life and ease of installation and operation, the lifetime cost of DI pipe is lower than that of other pipeline materials.

Operation

Ductile iron pipe can save a utility on operating costs in several ways, including pumping costs, tapping costs, and hydraulic performance. DI pipe is more energy efficient during pumping operations than other competing pipeline materials. The higher tensile strength of the DI pipe allows its inside diameter to be larger, creating a much larger inside area than other pipeline materials.

This larger diameter reduces the friction force needed to push water or other liquids through the pipe, which reduces the energy required for a pump, saving hundreds of thousands of dollars a year in electricity costs to a utility and its customers. In addition, the larger inside diameter of Ductile iron pipe creates less hydraulic head loss in a pipe system. The less head loss allows water to flow further out into a system via gravity once water is released from a water/storage tank than other pipeline materials.

Environment

Ductile iron pipe is considered the best material choice for the environment. DI Pipe is manufactured from up to 95 percent recycled scrap metal and non-toxic materials and can be easily recycled after use. With its long service history and recyclability, there is no concern about leachate containments affecting the water system. Because of its manufacturing process and the production of its raw materials, DI pipe has a smaller carbon footprint than other materials.

Clean Water for Generations

As we celebrate the 50th anniversary of the Safe Drinking Water Act, which helps protect the quality of drinking water in the U.S., whether from above-ground or underground sources, let’s remember the importance of Mother Nature's essential gift. Our society has made significant improvements in providing potable water worldwide since 1974. After reading this #IronStrong blog, I hope you better understand the critical systems and processes needed to treat and distribute water and how selecting Ductile iron pipes for future water infrastructure needs can significantly improve the provision of clean water to the public for generations to come.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, your local McWane Ductile representative is equipped with the expertise to assist you. Many of our team members have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

References:

-

U.S. Environmental Protection Agency, “Safe Drinking Water,” Accessed September 5, 2024. https://www.epa.gov/watersense/statistics-and-facts

- U.S. Centers for Disease Control and Prevention, “Global Water, Sanitation and Hygiene,” Accessed October 3, 2024. https://www.cdc.gov/global-water-sanitation-hygiene/about/

- U.S. Centers for Disease Control and Prevention, “Groundwater Awareness Week,” Accessed October 3, 2024. https://www.cdc.gov/drinking-water/event-name/groundwater-awareness-week.html

- U.S. Environmental Protection Agency, “Drinking Water Regulations,” Accessed September 23, 2024. https://www.epa.gov/dwreginfo/drinking-water-regulations