JUST WHAT IS SAFE YIELD?

The term safe yield refers to the amount of water available to be pumped to a treatment facility during a specified event, normally a record or 100-year drought. This term can apply to surface water sources (rivers, reservoirs, etc.) or aquifers.

Factors affecting this quantity can be river flow-by requirements for aquatic life, saltwater intrusion of aquifers along coastal areas, evaporation/usage of reservoirs during droughts, and water system customer demand — just to mention a few.

Although a utility can attempt to mitigate this shortfall during warranted conditions by using various conservation measures, the goal of the utility is to increase its safe yield as it can directly relate to economic development, potential limiting of new customer connections, or quality of life in general when ample water supply is limited.

WHAT FACTORS CAN AFFECT THE SAFE YIELD OF A WATER UTILITY’S WATER SUPPLY?

Natural Occurrences:

Several effects of mother nature, such as a drought or even a weather disaster that may contaminate a raw water source, can create a diminished safe yield for a utility's raw water supply. Short-term solutions for curtailing safe yield volumes may include conservation measures imposed on system demands, such as:

- elimination or curtailment of irrigation,

- conservation rate structures,

- a requirement of xeriscape landscaping,

- or possibly quantity limitation of customer usage, for example.

Ultimately, the utility should develop plans to obtain an additional water source or connect to a system with acceptable safe yields that could provide additional water supply even under these conditions. Aquifer raw water supplies also have a safe yield. When these systems are diminished by having more out-flow than in-flow, whether natural infiltration or pumped storage, the lower gradient in the aquifer can create significant issues regarding safe yield quantities available.

Man-Made Occurrences:

Arguably, overusing an aquifer system by extensive pumping is a manmade occurrence regarding safe yield availability. Other extensive "opportunities" exist in our country wherein a water utility's raw water supply can be dramatically affected by man-made occurrences.

One notable recent occurrence is the train derailment in East Palestine, Ohio. “A prime worry is the train's release of vinyl chloride." The chemical — primarily used to make a plastic called polyvinyl chloride, or PVC — is classified as a Group A human carcinogen by the Environmental Protection Agency and releases even more toxins when burned. PVC is commonly found in many products, including waterpipes, medical devices, vinyl flooring, and siding.

The environmental and health effects of plastic production are well documented. The process exposes workers and surrounding communities to vinyl chloride, asbestos, and the industrial forever chemicals known as PFAS.1 The East Palestine water system takes water from five wells roughly a mile from the derailment site. Fortunately, as of February 15, 2023, there was no indication of contamination of these five wells or the treated water.2

However, if circumstances were different regarding well or railroad track location, this vinyl chloride classified as a Group A human carcinogen could have contaminated the raw water supply, thus virtually leaving zero safe yield for that community. Water quality testing in East Palestine and surrounding communities continues.

SAFE YIELD STRATEGIC PLANNING BY THE UTILITY

It has been noted above some ways in which a water utility can, in a point source manner, stem its usage to stay within safe yield boundaries. However, another utility focus should be reducing unaccounted-for water within its system. If a utility has a safe yield concern, allowing water to escape the system beyond acceptable limits may create the need for, or at least hasten, that need for an alternative supply — usually a costly proposition.

One key component in minimizing and reducing unaccounted-for water is the proper selection of pipeline material. Obviously, the underground infrastructure of the water utility is out of sight — and many times, leaks underground are out of sight as well.3 For more information on unaccounted-for-water, read my blog here: Unaccounted-for Water - The Phantom of The Forgotten City.

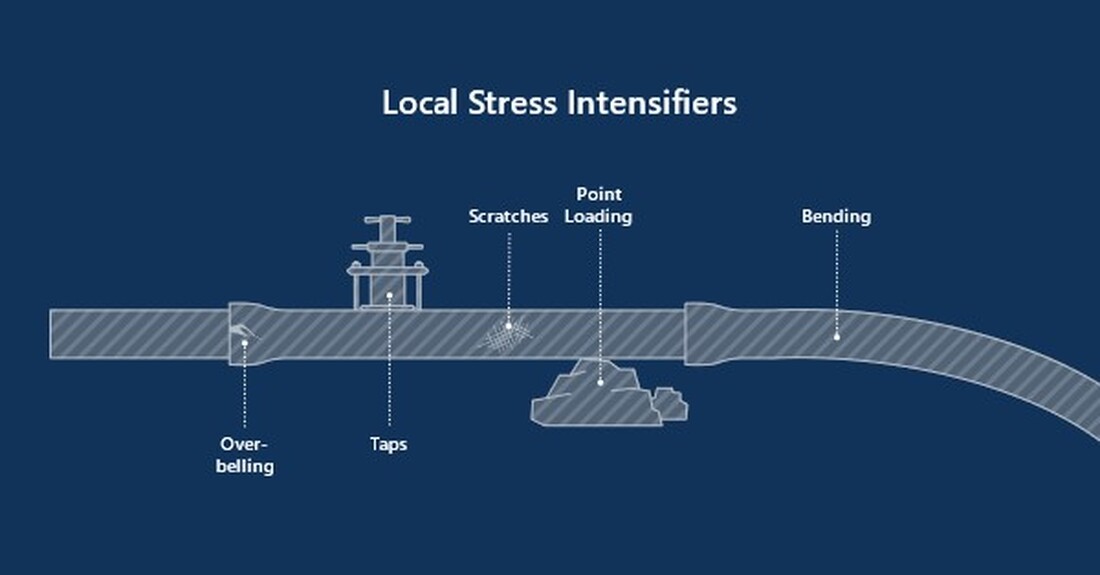

When a pipeline is installed, certain “stress intensifiers” come into play over time. Some eventually cause leaks or ultimate pipe failure. Due to the strength and resiliency of Ductile iron pipe (DI pipe), these stress intensifiers have no effect as opposed to other materials such as PVC.4

Conclusion: Pipeline Material Choice Is Critical to Maintaining Safe Yield

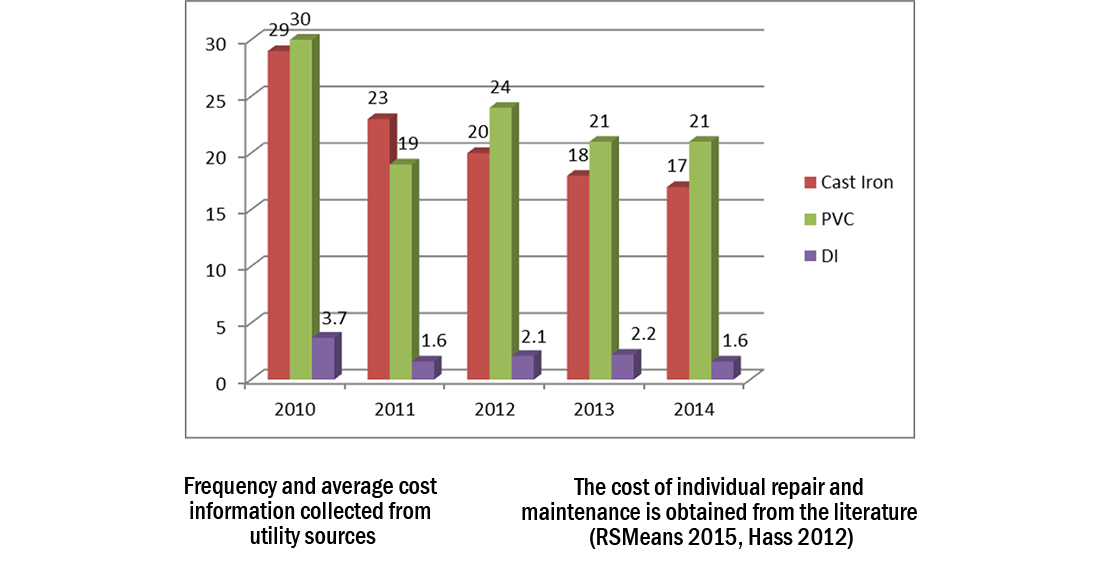

Research findings have shown that fewer leaks, and thus less water loss resulting from those leaks, occur in systems utilizing DI pipe, as shown in the study by the University of Michigan entitled “A Framework to Evaluate the Life Cycle Costs and Environmental Impacts of Water Pipelines."5

Additionally, studies by utilities validate that using DI pipe can reduce volumes of unaccounted-for water over time as another alternate pipe material is replaced in the system with Ductile iron.6

Another validation of Ductile iron pipe’s sustainable ability to provide water service is the estimated service life of the material. The “Buried No Longer Report,” authored and published by the American Water Works Association, contains charts showing DI pipe to have a 105-year estimated service life. Other materials, including PVC, often have less estimated service life.7

There exist many essential components in running a successful water utility. The element of safe yield can seriously affect the water utility’s viability. Maintaining "healthy" safe yield volumes, even when selecting the type of pipeline material for the system, is critical.

Need Assistance with Your Waterworks Project?

If you have any questions regarding your water or wastewater infrastructure project, contact your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to educate and assist water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

References:

- Mitchell, Schuler (2023), “The Myth of Safe Plastics Persist Despite Risk of Disasters Like East Palestine." The Intercept, February 18, 2023.

- Governor Mike DeWine news release, February 15, 2023, Wed 3:00 PM.

- Mundy, Roy. “Unaccounted-For Water – The Phantom of the Forgotten City.” April 16, 2020. McWaneDuctile.com.

- Rickvalsky, Ken. “Ductile Iron Vs. PVC – Writing the Wrongs.” November 9, 2022. McWaneDuctile.com.

- Thomas, Albert; Mantha, Bharadwaj; Manassa, Carol; “A Framework to Evaluate the Life Cycle Costs and Environmental Impacts of Water Pipelines.” ASCE Pipelines Conference (2016).

- Mundy, Roy. "Why Use DI Pipe? An Interview with Bill Dunnill, Consolidated Utility District." May 5, 2019. McWaneDuctile.com.

- American Water Works Association, “Buried No Longer.” 2012.