First, let us establish that all Ductile iron pipe, whether using push-on joints such as Tyton Joint® and TR Flex® Restrained Joints or Mechanical Joint pipe requires the gasket to be properly lubricated prior to joint assembly. Secondly, there is no such thing as too much lube when appropriately applied, especially when using McWane Sure Stop Restraining Gaskets. In this Iron Strong Blog, we will focus on why it is recommended to use the lubricant supplied by the pipe manufacturer.

Why Use Lubricant in the First Place?

Many different types of pipe with gasketed joints are used in the water utility industry, from Ductile iron to PVC. All these pipes require a field applied lubricant to minimize friction upon the gasket when putting pieces together. For push-on joint pipe, the lubricant allows the spigot to slide more easily into the adjoining bell while it compresses the gasket and reduces the chance of rolling gaskets during the homing of the pipe.

IMPORTANT NOTE: With push-on Ductile iron pipe joints, the one place we NEVER want the lube to be is on the UNDERSIDE of the gasket. Friction between the metal gasket cavity and the rubber gasket is essential to a successful assembly.

There are differences in the lube used on various pipeline materials. For example, the lube for concrete pipe is not the same as the lube required for Ductile iron. While there are many "pipe lubricants" available at various utility supply houses, all three manufacturing facilities of McWane Ductile choose to supply only two specific brands, Phoenix™ Pipe Joint Lubricant, and Black Swan® Pipe-Lube.

The two specific lubes provided by McWane Ductile have been explicitly designated for use with our pipe and fittings based on the harmless yet productive interaction between the iron, the factory-applied seal coat, the factory provided gasket, and the lube. All have been tested to maintain our certified compliance with the NSF/ANSI Standard 61 (NSF-61), otherwise known as the Safe Water Drinking Act.

Both lubricants are a non-toxic, water-soluble material, imparting neither taste nor odor to the conveyed water. The lubricants do not support the growth of bacteria. Both are NSF-61 approved and are very suitable for use in both hot and cold weather applications.

The NSF/ANSI 61 Standard is a national standard related to water treatment. The Standard establishes stringent requirements for the control of equipment that comes in contact with either potable water or products that support potable water production. Want to know more about the NSF-61? Check out this blog by my colleague Dan Henrie, where he provides a great explanation of its importance in the waterworks industry.

How to Properly Apply Lubricant Per the DIPRA Installation Guide, Section 3.6, Push-on Joints

According to the Ductile Iron Pipe Research Association (DIPRA), "Apply lubricant to the exposed surface of the gasket and plain end of the pipe or fitting in accordance with the pipe manufacturer's recommendations. Do not apply lubricant to the bell socket or the gasket's surface in contact with the bell socket. Lubricant is furnished in sterile containers, and every effort should be made to keep it sterile."

PRO TIPS for applying lubricants:

- Do not alter the consistency.

- If liquid appears on the surface, simply mix well before using.

- Clean pipe and gasket surfaces thoroughly.

- Make sure the gasket is properly sealed.

- There is no such thing as using "too much lube," especially with restraining gaskets.

- Apply pipe lube using a CLEAN sponge, cloth, glove, or brush.

- Be sure to apply it evenly over the entire surface requiring lubrication but avoid spots.

- Do not place lubricant in the ring groove.

- It is best to lubricate all three sides of a Mechanical Joint gasket BEFORE sliding it onto the spigot end.

PRO SAFETY TIP: The lubricants have the characteristics of soap. Prolonged contact with the skin could cause irritation. Keep lubricant from coming into contact with the eyes. In case of contact with eyes, flush with water for 5 minutes. If discomfort persists, get medical attention.

Aerosol Versus Solid Lubricants, Which is Best?

Some contractors have chosen to use aerosol applied lubes. These spray lubes offer ease of use for the person applying the lube due to a much cleaner job compared to the tub lube, which is usually applied by brush/rag or by hand.

With spray lubes, it is challenging to ensure good gasket coverage, and most importantly, the lube tends to dry or "set-up" very quickly and becomes tacky in warm weather conditions, causing issues when homing pipe.

These spray lubes often require applying water in warm weather conditions to maintain a smooth/slick tendency. If the lube is not watered during warm weather conditions, installation issues like rolled gaskets can happen, making it tough to home Tyton Pipe, especially when using a Sure Stop 350 Restraining Gasket. Simply put, spray-on/aerosol lubricants aren't recommended for use with Ductile iron pipe and fittings.

PRO TIP: The pipe manufacturer should supply the proper amount of lube with your order of pipe. When preparing pipeline materials for installation, make sure adequate Phoenix or Black Swan lube is on hand. If you need more, contact your local McWane Sales Representative.

What About River Crossings and Subaqueous Installations?

All the above-mentioned information pertains to buried or above ground installations of pipe. But let’s not forget to mention a specific lube called NO-OX-ID® for subaqueous applications. This lube is supplied by McWane Ductile on a minimal basis for River Crossing pipe and underwater applications such as TR Flex pipe installed under a lake.

Do It Right to Ensure You’re Watertight!

It's easy to overlook the importance of proper lubricant when installing your pipeline system. Certain lubricants are formulated best for certain pipe materials and their gaskets. As stated above, be sure to use the lubricant provided by your pipe manufacturer, whatever your choice of material may be.

In addition, by following the recommended installation guidelines when installing Ductile iron pipe, you can take significant steps in ensuring a sound, "Iron Strong" pipeline installation that will last for generations.

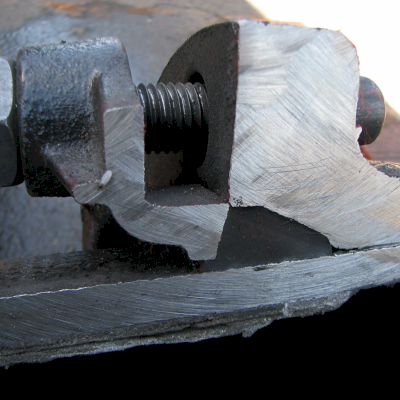

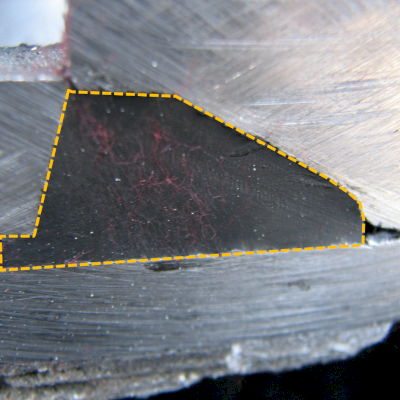

AN IMPORTANT TRUTH: Dry assembly of Mechanical Joints (MJ) will decrease the effectiveness of your wrench work. Dry MJ assemblies contain friction as well as torque. The friction dissipates shortly after and the bolts may appear "loose" the next day, costing you anywhere from 30 to 50 lbs. of previously applied torque, which means leaks! Lubricate everywhere you see a yellow dotted line in the picture below and your MJ Joints will remain first-tight, forever-tight.

Need Assistance with Your Waterworks Project?

If you have any questions regarding the use of above-ground, below-ground, or subaqueous lubricants for Ductile iron pipe installations, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.