EVEN IN THIS MODERN ERA, we are still concerned with many of the issues that early civilizations faced when providing water to our communities, such as supply and demand, pipeline construction and upkeep, cleanliness, conservation and cost. In the fall of 2018, McWane Ductile’s Senior Regional Engineer, Roy Mundy, had the opportunity to interview Consolidated Utility District General Manager Bill Dunnill. The two gentlemen, both with utility management experience, had a candid conversation about Bill’s day-to-day challenges, successes and his preferred choice of pipeline material. The following are excerpts from their discussion.

Roy Mundy: Tell us a little bit about yourself. You are obviously an experienced, well-credentialed and well-respected leader in our industry.

Bill Dunnill: I graduated from Bradley University with a B.S. in civil engineering in 1975. I spent over 16 years in the oil and gas industry, where I was responsible for the transportation of crude oil and natural gas. During this tenure, I also served as mayor of a small southern Illinois community, which introduced me to public utilities. This led to my migration to Tennessee and, ultimately, General Manager of Consolidated Utility District, which is the sixth largest public water purveyor in the state.

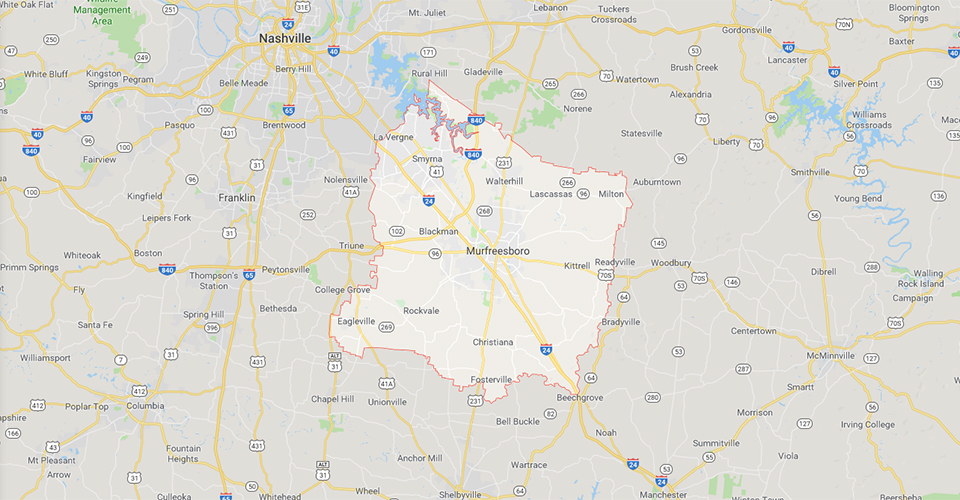

Mundy: Tell us about the Consolidated Utility District (CUD).

Dunnill: CUD has more than 55,000 active customers and 517 square miles of service territory. Our water plant averages over 10 million gallons per day (MGD) and peaks at 14 MGD. The customer base consists of 97 percent residential, 2.5 percent commercial and industrial and 0.5 percent wholesale to other utilities. Our water source is the east fork of the Stones River with an intake at the headwaters of J. Percy Priest Lake. The current customer growth is just over 2,100 per year, with an ever-increasing percentage of commercial and industrial growth.

Mundy: It is my understanding that CUD has more than 1,300 miles of pipeline? What is the approximate makeup of pipeline materials in your system?

Dunnill: We currently have more than 1,400 miles of pipe, which consists of:

- Less than 1 percent asbestos cement (AC)

- Less than 1 percent cast iron (CI)

- 71 percent polyvinyl chloride (PVC)

- 28 percent ductile iron pipe (DIP)

Mundy: Many water systems across the country are striving to control system demand in order to preserve drinking water, a precious commodity, to the fullest extent possible. Tell us how you have approached this at the Consolidated Utility District.

Dunnill: CUD uses a multi-pronged approach:

- We have instituted an inclined block rate to encourage customer conservation.

- We have significantly reduced flushing requirements by eliminating dead ends to improve circulation. This includes employing throttle valves to jump across pressure zones.

- We’ve tied continuous consumption notifications from our AMR metering system to our automated dialer in the office to notify customers of potential leaks.

- We’re actively replacing an inferior and aging infrastructure.

- We have significantly improved our repair practices.

- We have an extremely aggressive construction inspection program to ensure new installation meets specifications.

- We have an extremely aggressive leak detection program that employs best practices to quickly locate leaks.

- Finally, we have done a much better job with material selection, which includes using only ductile iron pipe for all transmission and distribution mains.

Mundy: CUD has a very impressive and comprehensive approach to this issue. Have you seen any results regarding implementation of these measures?

Dunnill: Our unaccounted-for water has dropped significantly. Not only is our Infrastructure Leakage Index one of the lowest in the nation, but our 12-month average water loss also now hovers around 10 percent and will drop even further once we get some of our older infrastructure replaced.

Mundy: One key component in your plan to control system demand is water loss reduction. Coming back to the types of pipeline material in your system, do you monitor the percentage of leaks based on the material of the pipe? Tell us what you’ve found.

Dunnill: Absolutely! Our experience shows that AC is about 10 times as likely to fail as PVC. Cast iron runs about five times as likely as PVC. Conversely, we have only one fifth the leaks on DIP as PVC, and most of those are caused by physical damage from someone working around the pipe. Hence, CUD now specifies only DIP on all transmission and distribution mains.

Mundy: In your opinion, are there other advantages to using ductile iron pipe beyond what has been mentioned?

Dunnill: Yes. We live in what I call “hard rock” country. Leaks rarely surface. Instead, they follow the trench line until they find a fracture and disappear into the Earth. Acoustic properties of the pipe material become extremely important to locate leaks. The acoustic properties of ductile iron pipe are exceptional and make locating

Mundy: Have you done any studies on the cost of ductile iron pipe vs. PVC regarding new development projects in your service area?

Dunnill: When we changed our specs in 2014, the cost to the developer was a consideration. We made some concessions in service line materials and even DIP wall thickness. The net increase was about $370 per lot at that time. Although not insignificant, it was miniscule in comparison to the cost of the lot, and the long-term benefit to CUD ratepayers is tremendous.

Mundy: So, in summary, you believe that choosing ductile iron pipe as the pipeline material of choice by CUD has benefitted your customers?

Dunnill: DIP is the only legitimate choice in hard rock country for the long-term benefit of CUD’s ratepayers. Maintaining a stable infrastructure while providing affordability or the end user will continue to be a challenge for water professionals.

Need Assistance With Your Water Infrastructure Project?

McWane Ductile would like to thank Bill Dunhill for his time and expertise in providing an open and honest conversation about how CUD successfully addresses these issues daily. We hope you found this information helpful and informative.

McWane Ductile offers multiple services for our customers extending far beyond manufacturing ductile iron pipe. From design to installation, we take great pride in providing education and training to water professionals throughout the water and waste water industry. Together, we are Building Iron Strong Utilities for Generations!

Check out all our digital offerings: