In this third installment about Sustainability and Resiliency for our Iron Strong Blog, we are focusing on the resiliency of pipe and pipelines as a result of natural disasters such as storms, floods, and wildfires. While earthquakes and seismic events also need to be considered, much has been written on those aspects and we will discuss them in our next installment. Resiliency means many different things to many different people, and its definition is often a matter of perspective and need. Put simply, resiliency is the ability to survive, resist, or recover from damage due to some external hazard.

When it comes down to it and to simplify, the resiliency goal water utilities would strive for is for their pipelines to remain unbroken and leak-free after a hazard event. The United States Environmental Protection Agency (EPA) lists several potential hazards to water systems in its publication Systems Measures of Water Distribution System Resilience, so let’s look at those that would most likely affect pipelines.

Resiliency and Its Importance

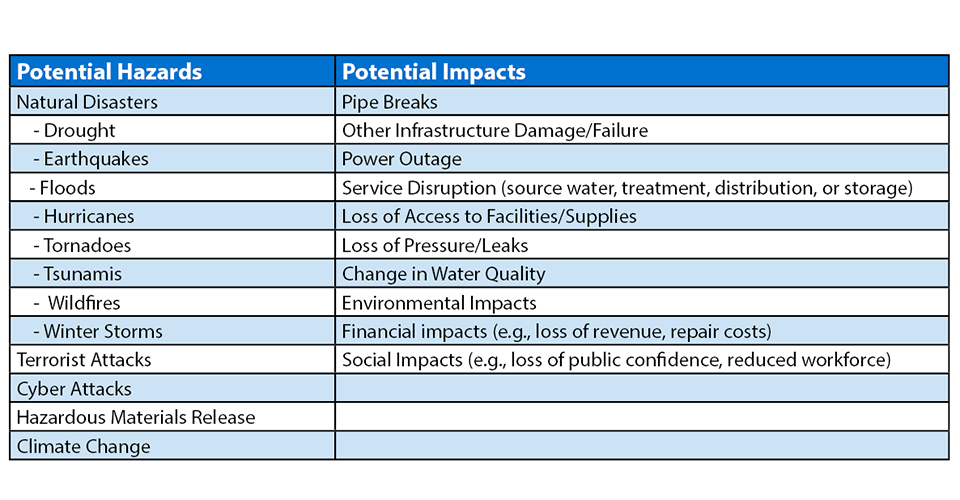

According to the EPA report mentioned above, the potential hazards and their impacts for consideration by pipeline operators would include:

When it comes to water and wastewater transmission, distribution, and collection systems, the obvious direct result of some of these hazard impacts are loss of fire protection and degradation of public health due to lack of clean potable water. These are critical needs provided by water systems so much so that, while people may be able to get by without electrical service for days, being without clean potable water and the ability to fight fires can result in catastrophic loss of life and property.

Resiliency and Pipe – All Pipes Are Not Equal

Why does all this matter when considering pipe materials? Let’s take a look at the potential hazards identified by EPA and those that would most likely affect pipe and pipelines.

-

Drought

- While at first, drought may not seem to have much impact on pipes and pipelines, the effect may be more long term and slower to propagate. In some areas suffering from drought, water tables are lowered from well pumping to the point where subsidence occurs even to the point of sinkholes forming. When this happens, pipelines could lose their underlying bedding and trench support. Lesser pipe materials that rely on side-fill support to resist external loads, pipe crushing, or collapse would result.

- Additionally, bearing area for thrust restraint blocking would be weakened, and pipelines not restrained would see joint separations resulting in failures, road damage, and service disruptions. This weakening is an issue some utilities are just starting to recognize.

-

Earthquakes (and Other Seismic Events)

- As mentioned earlier, this is something we will discuss in the next Iron Strong Blog, but a quick review of how pipes and pipelines are impacted is warranted. In earthquakes, pipes and pipelines are affected in several well-documented ways, but the most familiar are shear forces from fault movement and joint separation forces from ground dislocation and liquefaction.

- Ductile iron is the one pipe material listed in the ISO 16134 International Standard for Earthquake & Seismic Resilience due to its very high tensile strength, joint strength, high deflection, and strain capacity. New Earthquake Resistant Ductile Iron Pipe (ERDIP) systems that incorporate expansion fittings with high axial ranges have improved this resilience to an even higher level.

-

Floods

- People often do not consider water system and wastewater pipeline system impacts from floods until the waters recede. Then, pumps are restarted, and flow returned. At this point, the saturated ground often results again in loss of side-fill support and thrust bearing strength. Additionally, pipe materials with such low density that they float in water, will have high potential to rise through the ground. This loss results in joint stress and separations, many of which will result in smaller leaks rather than significant failures. Many years after the event, utilities who have experienced extreme flooding have documented high amounts of unaccounted-for water due to the many smaller leaks. Another flooding concern is exposed or above-ground pipelines and subaqueous crossings. High river flows can undermine or washout these pipelines and their support systems.

-

Hurricanes

- Hurricanes are associated with two primary causes of damage: wind and flooding. Pipelines, being primarily buried, are typically not affected by wind, but the storm surge and resulting flooding have often changed shore area topography. Some storms have closed channels, and some have created new breaks in barrier islands and coastal areas, washing roads out wholly. The storm surge effect can be similar to flooding previously described but often adds a higher degree of immediate impact while still resulting in longer-term damage.

-

Tsunamis

- The impact of a tsunami can be more immediate and violent than even a storm surge of a hurricane, but due to its shorter duration, may not have the longer-term effect associated with massive long flooding events such as Hurricanes Harvey (2017) and Katrina (2005) had on the Gulf Coast. Washouts and undermining should be more readily apparent, and multiple longer-term leaks less prevalent.

-

Wildfires

- Unlike the prior hazards where too much water is involved, wildfires present a different challenge: too much heat. Too much heat from the wildfires not only hampers firefighting efforts but causes pipe failures directly and indirectly. Pipe failure by fire occurs when fires generate temperatures that exceed the melting point of the pipe. With thermoplastics, this melting point is relatively low, especially when compared to iron pipe. This melting of pipe has occurred particularly in California's wildfires of 2018. Indirect pipe failure occurs when high temperatures significantly weaken pipe, but failure does not immediately happen.

- Thermoplastics located downstream that have been structurally affected by heat but have not been completely melted are susceptible to failure when pressure is reintroduced. In addition, Polyvinyl Chloride (PVC), of all the plastic polymers, has been implicated primarily in causing the most severe problem in firefighting today because PVC releases hydrogen chloride gas when as it melts in a fire. Many plastics produce large volumes of pulmonary irritant gases when burned. The firefighter is at fatal risk if he does not know that plastic covered cable is involved in a fire. (U.S. EPA)

-

Hazardous Materials Release

- While other disasters may appear to be more common, that may be because of their larger size and scope. Hazardous material spills, primarily chemical and petrochemical in type, often prove to be more complex to resolve due to contamination that can only be removed through extensive replacement efforts of pipe, surrounding soils, and residue in the system itself.

- Pipes that can be permeated by toxic chemicals are at a much higher risk. These risks may seem small, but a fuel spill from a tanker truck accident could conceivably contaminate an entire distribution system. Leaking fuel tanks have resulted in many main replacements as well as contaminated ground remediation. If permeation occurs, serious water quality consequences carry forth as contaminated water is distributed to customers, sometimes resulting in lawsuits, etc.

- Check your pipe material handbook for a list of contaminants that can permeate the pipe material.

-

Climate Change

- We are all aware of the climate change discussion, and, as we have said before, change is constant. The effects of climate change can be subtle and create hazards or exacerbate others. Hurricanes, droughts, and other phenomena can be more numerous or intense, but adapting to these changes through better design and material selection with long term performance and lesser environmental impact should also be considerations. The ENVISION program takes these factors into account and should be incorporated as much as possible into both project planning and system planning.

-

Other Hazards – Tornadoes, Cyber-Attacks, Thunderstorms, etc.

- Another hazard affecting pipelines in virtually all these instances is a loss of power, and the resulting pump shut off and restart. In some cases, sudden pump shutdowns can cause vacuum conditions, and restarts will certainly cause surges or water hammer. In instances where pipeline integrity is compromised, surge pressure wave pipeline failures from pumps being restarted could create system problems and hamper other active rescue and recovery operations.

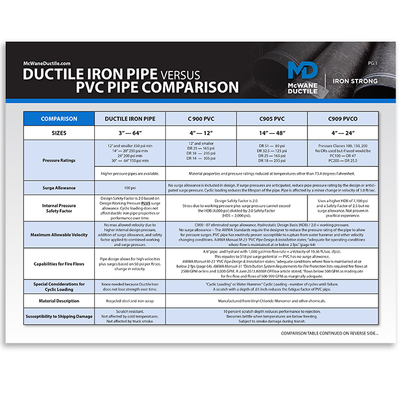

What is the difference and advantage of Ductile iron over PVC pipe? Many things! Use this handy comparison sheet to ensure you specify the safest, durable, and longest-lasting pipe for your next project.

As we discussed, there are many factors to consider when pipeline resiliency is part of the design discussion, as it should always be, but let’s list them:

- Great structural material strength to resist crushing and pulling forces (aka high tensile strength).

- Great joint integrity with both the ability to deflect from movement and alignment plus the ability to prevent separation.

- Great survivability from extreme temperature changes: high temperatures from wildfires, extreme cold from polar vortexes.

- Great resistance to penetration by contaminants.

- Minimal contribution to climate change both in the manufacture, installation, use, and recycling after use.

Resiliency and McWane Ductile Iron Pipe

-

Inherent Structural Strength:

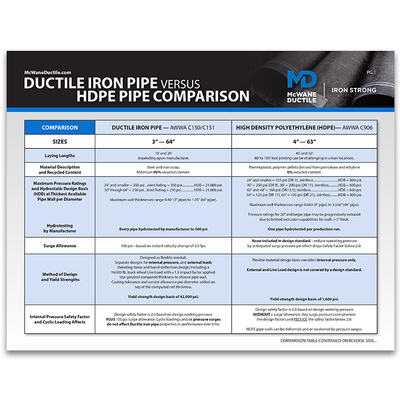

- Ductile iron pipe is a very high strength material with physical properties conforming to ANSI/AWWA C151/A.21.51 Design requirements of 60,000 psi Tensile Strength, 42,000 psi Yield, and 10 percent Elongation. Materials like plastics can have less than 1/10th of the tensile strength of Ductile iron pipe. This lack of tensile strength means that your weaker pipe can be torn apart or easily crushed from these hazards, while Ductile will just shrug them off.

- Ductile iron pipe has sufficient ring strength to shrug off external loads in many installations easily. A Type 1 Trench, which offers minimal side support is suitable for the most common Ductile iron pipe sizes but never for plastic pipes of any type. For more information on the importance of depth of cover when installing Ductile iron pipe, see this helpful Iron Strong Blog by my colleague, Gary Gula.

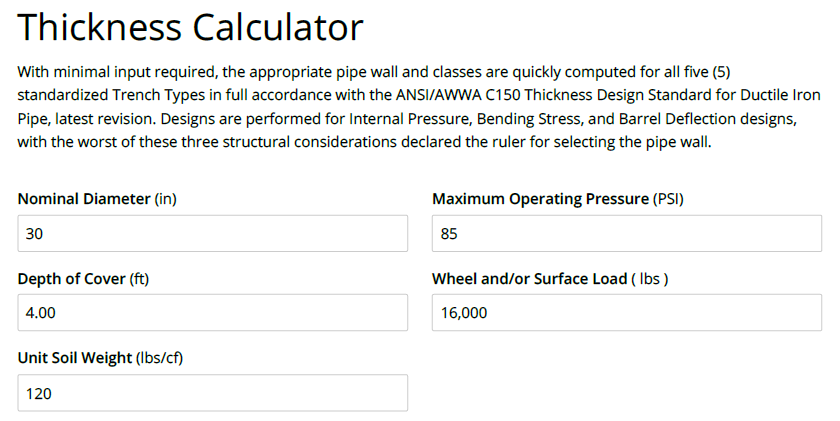

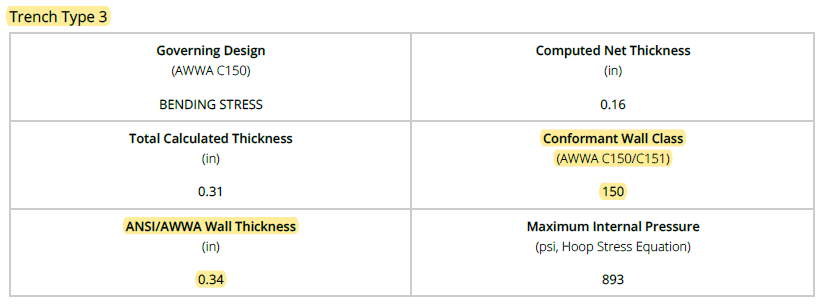

- The McWane Pocket Engineer is a great tool to help calculate appropriate pipe wall and classes for all five Trench Types and can be found at pe.mcwane.com.

Higher strength, longevity, superior resistance to mechanical damage, corrosion resistance with coatings, and fire resistance are just some advantages of Ductile Iron Pipe over HDPE Pipe! Use this handy comparison sheet to ensure you select the proper pipe for your next project.

Resistance to Joint Separation:

Ductile iron pipe can be easily and cost-effectively restrained by using the Sure Stop 350 Gaskets. Utilizing these restraining gaskets simply involves using a different gasket and no added labor or preparation for installation. Other pipe materials require expensive, labor-intensive, pipe damaging, external restraint systems, or costly time-consuming equipment and personnel.

In areas where more significant joint separation stresses are possible, McWane Ductile can provide TR Flex® joints and the Seismic Flex Coupling. Both offer the highest level of dependability against joint separation.

- McWane Ductile’s Ball & Socket Joint provides up to 15 degrees deflection in extremely high degree deflection scenarios while also providing end pull strength exceeding that of solid plastic pipes.

-

Other Factors to Consider in Pipeline Resiliency Design

- Ductile Iron pipe does not burn or melt from wildfires, unlike plastics. During the annealing process, McWane Ductile iron pipe is heated to over 1,800 degrees. It also is not affected by a reduction in temperatures like plastics, which have a loss of impact strength at low temperatures.

- Iron is not permeable. If the risk is deemed even significantly high, special gaskets can be utilized that allow Ductile iron pipe to be installed even in the most contaminated environments.

- McWane Ductile iron pipe is a natural, recycled, and recyclable product, as discussed in our last Iron Strong Blog. It neither contains nor creates carcinogens during manufacture, production, or use as other materials can and do, making it safe for your customers and the environment now and for generations.

If you would like to read Part 1 or 2 of our Sustainability and Resiliency series, click the links below:

How Does Ductile Iron Pipe Answer the Challenge of Sustainability and Resiliency?

Sustainability & Resiliency – The Impact of Recycling and Using Recycled Products

Need Assistance with Your Waterworks Project?

Every system is unique and has its own challenges and needs. McWane Ductile is committed to building resilient and sustainable Ductile iron pipe utilities that will last generations. Our experienced and specially trained Engineers can help your utility identify the greatest needs and how best to meet those unique challenges by assisting you with the selection of the best materials for your system and project. For more help and information on how McWane Ductile iron pipe can help you make your system more Sustainable and Resilient, please contact one of our ENVISION Sustainability Professionals (EnvSP).