Polyethylene encasement (polywrap) has been used since 1958 to protect ductile iron pipe from corrosion. It is the most popular, economical, and successful method for protecting pipe from corrosion.

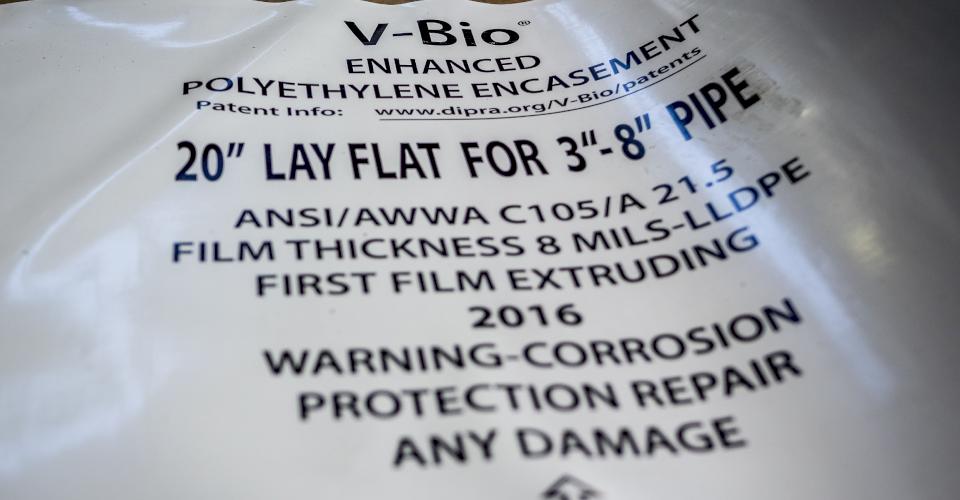

A new advancement in polyethylene encasement called V-Bio® adds additional protection by inhibiting the formation of corrosion cells under the wrap. McWane Ductile added V-Bio polywrap to its line of products in 2015. Adding a few steps to your pipe installation with V-Bio is an Iron Strong decision that will benefit your pipeline for generations.

Installing V-Bio

Step 1

Unroll a section of V-Bio 2 feet longer than the section of pipe you will be covering to accommodate the overlap over the pipe joint. You’ll need the extra 2 feet to cover the joint once it has been connected to the next pipe.

Pro Tip: Dig a shallow hole near where the bell of your pipe will lay in the trench. This bell hole will allow you to pull the V-Bio under the joint once it has been made up.

Sales representative Aaron Loosli demonstrates the proper installation of V-Bio Polywrap below.

Step 2

Use a sling to lift the pipe in the air.

Pro Tip: Watch out for pinch points as the sling or choker tightens around the pipe. Never allow yourself or your coworkers to be in the line of fire by working under a suspended load.

Step 3

Slip the V-Bio tube around the pipe starting at the spigot end. The strap will be supporting the pipe in the middle so bunch it up like an accordian. Make sure to brush off any dirt or debris that may be on the pipe.

Step 4

Pull the V-Bio about 1 foot away from the spigot end of the pipe, fold the V-Bio over so it sits tightly against the pipe, and apply a length of tape all the way around the edge.

Tech Tip: V-Bio enhanced polyethylene encasement works best when it is tight against the pipe. Enhanced polyethylene encasement consists of three layers of co-extruded linear low density polyethylene film that are fused into one. The inside surface is infused with a proprietary blend of antimicrobial additives which mitigate microbiologically influenced corrosion and a volatile corrosion inhibitor to control galvanic corrosion.

Step 5

Lower the pipe into the trench and assemble the joint. Pull the overlapping portion of V-Bio from the old section onto the new section. Secure the V-Bio with Polyethene tape.

Pro Tip: If are working in a wet muddy trench or if it begins to rain during your installation you will have some headaches. Do your best to keep the pipe clean but the most important thing is to make sure get the V-Bio tight around the pipe. Remember the poly wrap tape will stick to itself even when wet so use as much as needed to get the V-Bio in direct contact with the pipe.

Step 6

Slide the sling to the bell end of the pipe. Keep the pipe slightly lifted so you can pull the V-Bio to the bell. Pull the remaining slack, fold it tight against the pipe, tape V-Bio every 2 feet.

Pro Tip: Be careful when sliding the V-Bio along the pipe. During this step tears or rips may occur. These can easily fixed, but each tear will add to the overall installation time.

Step 7

Pull the V-Bio taut before placing a wrap of tape all the way around the pipe behind the bell. Then fold back the excess to make way for the next pipe in the line. There should be enough left to overlap and cover the next joint in the trench.

Step 8

Inspect the V-Bio polywrap for any cuts or scratches along the length of the pipe. Small cuts can be repaired with tape. For a larger hole cut a section of VBIO and use it to patch the damage.

Once you have the V-Bio installed closely inspect it for any rips, cuts, or tears. Chances are you’ll find a couple and if you do they will need to be patched before the pipe is buried. Small cuts can be repaired by placing an X of tape over them. For larger holes you will need to make a patch from scraps of V-Bio and taping it over the hole.

If you would like to learn more about the benefits of V-Bio polywrap and how it could be useful to your upcoming project contact your area sales rep.

Our friends at the Ductile Iron Pipe Research Association have created a 15 minute long video that goes into great detail on the benefits of V-Bio and a few different methods of installing it.