-

Acknowledging Our Hidden Responders

09/29/2022 In Environmental & Safety ServicesSummer has come to an end. Schools are in session, fall sports are well underway, and we look forward to the coming cooler days filled with fall festivities. Unfortunately, some days are also filled with wildfires, hurricanes, flooding, and other disasters in some regions of the country. Luckily, we have an extraordinary group of emergency professionals that respond to these various disasters, referred to as “first responders.” First responders have been a prominent topic in the news lately, especially with Hurricane Ian bearing down on the state of Florida and projected to turn over the eastern coast of the US as we speak.

-

How to Use the McWane Pocket Engineer Flow Calculator – Number 2 in a Series of 11

07/21/2021 In Products TechnicalHow much water can I get through that pipe? What size pipe should I use to carry that much water? Two similar-sounding questions that, in truth, are entirely different. Not to mention, both are missing the keyword to consider in resolving each question, that word being "efficiently." The McWane Pocket Engineer (PE) Flow Calculator quickly and easily answers all three concerns - flow rate, pipe size, and flow efficiency.

-

How to Use The McWane Pocket Engineer Volume Calculator – the First in a Series of 11

05/07/2021 In Products TechnicalIn recent years, an increasing number of locales and authorities have adopted greater controls of the water used in hydrostatic testing, flushing, and disinfection of utility pipelines, post-installation. Whether from a feeder hydrant to be metered, or when there might be a fee applied on the volume of water used, how does an engineer, contractor, or inspector compute the amount of water needed for these tasks? Sometimes it is required to demonstrate during flushing operations that the water inside a pipeline section has been “exchanged” a designated number of times during the specified flushing. So, just how much water does it take to fill or flush 1,500 feet of 12-inch class 52 DI pipe?

-

A Story of Water

04/17/2020 In Environmental & Safety Installation Products TechnicalEvery summer, I go backpacking with my family into the Uinta Mountains of Utah. The Uinta mountain range is enormous, very remote, and extremely beautiful. One of the most scenic areas in the entire range is called Red Castle. In this area of the Uintas rises a towering red monolith with peaks that reach straight into the sky, hence the name. Getting there requires a grueling 10-mile trek, but the beauty and serenity are well worth the effort...

-

How to Avoid Frozen Ductile Iron Pipelines Using Electrical Thawing

03/06/2020 In Installation TechnicalJust as we start to feel that spring is just around the corner, Mother Nature reminds us that we are still in the midst of winter and warmer weather may still be days away. Lower temperatures are great for skiing, sledding, and hot beverages by the fire. However, in some parts of the country, a lower reading on the thermometer means trouble for our water lines.

In extremely cold weather, the water in our pipelines can freeze, cutting off supply to our homes and businesses. This inconvenient problem can be remedied in Ductile iron pipelines through the process of electrical thawing

-

What is the Purpose of the Seal Coat on Ductile Iron Pipe?

07/20/2019 In Products TechnicalThe normal, stocking item for Ductile iron pipe products is lined and coated with a sealcoat that comes in your choice of black. Many water professionals wonder about the purpose of this coating, or paint, that gives Ductile iron pipe it’s familiar appearance. In this article we offer some explanation and history behind the application and advancement of the sealcoat.

-

What Is It Like To Tour A McWane Ductile Iron Pipe Plant?

12/13/2018 In Our Company TechnicalTouring a McWane Ductile Iron Pipe plant is a unique and memorable experience. You get the opportunity to see firsthand how we take just a few simple raw materials and convert them into the strongest, most reliable, most time-tested pipe material on the market today.

-

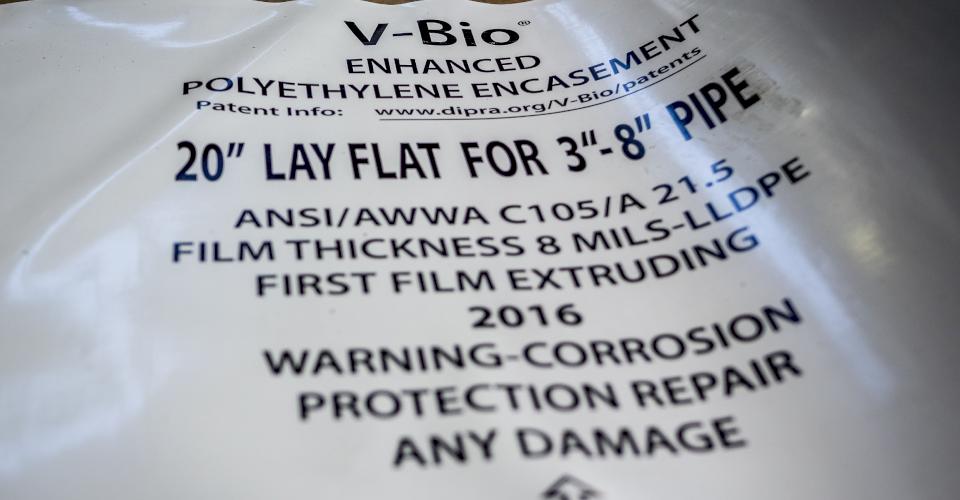

Eight Steps for Installing V-Bio® Polywrap (With Video)

04/06/2018 In InstallationPolyethylene encasement (polywrap) has been used since 1958 to protect ductile iron pipe from corrosion. It is the most popular, economical, and successful method for protecting pipe from corrosion.

A new advancement in polyethylene encasement called V-Bio® adds additional protection by inhibiting the formation of corrosion cells under the wrap. McWane Ductile added V-Bio® polywrap to its line of products in 2015. Adding a few steps to your pipe installation with V-Bio® is an Iron Strong decision that will benefit your pipeline for generations.

Latest Posts

- Developing an Asset Management Plan for Your Future Utility or Engineering Organization 12/04/2025 In Comparisons Industry

- Can Joining Water Works Industry Organizations Help You Grow Professionally? 10/21/2025 In Careers WaterWorks

- How Does Ductile Iron Pipe Provide Proven Resilience to Seismic Events? 09/04/2025 In Products Resiliency Technical

- How to Secure Green Reserve Sustainability Incentives Using State Revolving Funding & Ductile Iron Pipe 07/29/2025 In Energy Products Technical