Providing safe, clean water to customers of a water utility is unquestionably JOB ONE. Meeting this goal has always been a formidable challenge in many ways. Source water quality can change dramatically due to weather factors and other phenomena. Additionally, increasing drinking water standards throughout the years evidencing higher detection technology and more sophisticated medical research regarding the health effects of contaminants has required water systems in some cases to change treatment methodologies dramatically.

Should the pipeline material placed in a drinking water system in any way limit decisions of today or in the future regarding the water treatment methodology chosen to best provide safe, clean water to customers? I THINK NOT!

If We Only Knew Then What We Know Now

A recent story from Hamilton, Ohio illustrates this fact . . . “We’ve got about 21 miles of HDPE piping in our system now, and it is catastrophically failing, about 60 years ahead of when it should have,” Logan said. “This, back about 20 years ago, was the future of water mains, and unfortunately, the chemicals we use attack the pipe and then cause it to fail. So, we’re going back to iron piping.” – City of Hamilton, Ohio Executive Director of Infrastructure Jim Logan.

The cause of these failures has been identified as the City’s use of water disinfectant. Considering disinfecting water prior to sending out to the distribution system is not an option, the choice for infrastructure integrity then becomes to use plastic pipe or not.

We would suggest that not using plastic pipe is the better choice, especially considering the superior option of Ductile iron pipe (DI pipe). Hamilton is not entirely alone in its experience with plastics. There have been numerous other experiences with the premature failure of other plastic pipes such as Poly-B and polyethylene pipes in Canada. The use of these materials resulted in numerous lawsuits and the removal of those products from sale there.

For a comparison between Ductile iron pipe and HDPE, see this informative Iron Strong Blog by my colleague Ken Rickvalsy.

Water Disinfectants Can Be Corrosive to Plastic

Chlorine has been the "silver bullet" for the water industry to control disease-causing contaminants for over a century now. However, derivations of simply using free chlorine have been instituted due to potential water system components such as Trihalomethanes (THM's). Thus, a full range of options must always be available to the water utility to combat various contaminants. In the case of Hamilton, Ohio, this option was Chlorine Dioxide.

Although the Ductile Iron pipe industry has often stated there was too much unknown about the interaction of chemicals and plastics in water system treatment and operation to make plastic a viable alternative to iron pipe; little research had been done until these types of failures started to propagate.

Research being conducted now has shown disinfectant chemicals can have a corrosive effect on plastics in addition to the situation noted in Hamilton, Ohio. This effect could further be enhanced if systems introduce free chlorine into the water system beyond the point source application at the treatment plant.

The Issue: Oxidative Degradation

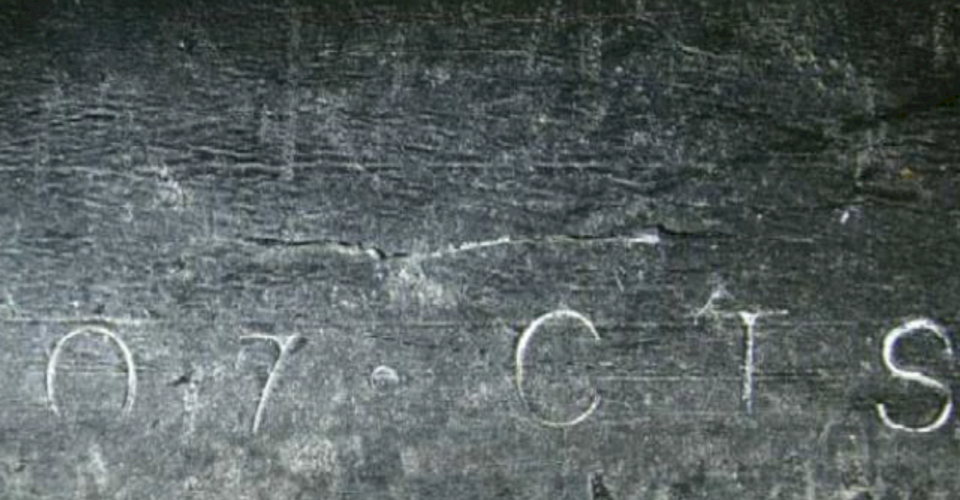

The scientific process causing these premature failures in plastic pipe products is oxidative degradation, which creates what is called Slow Crack Growth (SCG) in plastic pipelines. Slow Crack Growth occurs because the plastic's antioxidants are depleted by free chlorine, which is chlorine in the water.

“The residual disinfectant “concentration in the distribution system, measured as total chlorine, combined chlorine, or chlorine dioxide...cannot be undetectable….” - USEPA Surface Water Treatment Rule, 6/1989, 40 CFR 141.72 (b)(3)(i)

“...free chlorine is the amount of chlorine that can inactivate pathogenic microorganisms present in the water whereas total chlorine is the sum of combined chlorine and free chlorine.” - USEPA, “Understanding Disinfection Residuals”

There is now much research that has been conducted on disinfection and disinfectant residuals and their effects on plastic pipes, which have been listed at the end of this article.

Chemicals Negatively Affect Plastic Pipes

The short version is this; chemicals negatively affect the life and performance of plastic pipes through the formation and growth of cracks in the exposed pipe surface because the surface becomes brittle. It is also noted that this phenomenon occurs at a greater pace in warmer areas, so southern utilities will likely experience shorter life expectancy than northern utilities.

While the research is still young, it is reasonable to project that, with the surface cracking, more plastic surface is exposed via the crack depth, resulting in faster corrosion/degradation rates. Faster corrosion/degradation rates cause the cracks to widen and deepen, leading to pipe failure in much less than the 50- to 60-year design life.

This research has been primarily focused on oxidative degradation. Research has not focused on the potential for chemicals leaching into drinking water, at what concentrations, and the subsequent health effects of this leaching.

You might consider that, by using other types of plastic pipes such as Polyvinyl chloride (PVC), this would not be a concern, but current research shows the propensity for Slow Crack Growth in PVC as well as HDPE with the difference being slower growth rates of the cracks.

However, considering the greater rigidity of PVC compared to HDPE, it is no surprise that PVC failures show up as long, catastrophic cracks, particularly in long lengths of fused PVC.

JOB ONE is Water Safety – Go Ductile Iron

A water utility must always have the flexibility to address JOB ONE of the utility ─ providing safe, clean water to customers. Restricting the use of applicable water treatment methodologies to address both current and future drinking water standards due to certain materials utilized in the water system for pipelines is clearly putting the cart before the horse when it comes to the utility's priorities. See another Iron Strong blog about ensuring safe drinking water by my colleague, Jerry Regula.

Having sat in the seat of a water company manager for over three decades, I very much appreciate the transparency of the water utility leadership in Hamilton, Ohio, to be forthcoming to their customers about the problem they are now facing. Without question, different decisions would have been made in the past if today's information were known then.

Hopefully, now that science is proven regarding the failure of HDPE in this circumstance, water utilities can plan accordingly. Planning can include selecting pipeline materials for transmission and distribution pipelines that are not subject to oxidative degradation and have not been for centuries of use, such as IRON PIPE, and in today's world, DUCTILE IRON PIPE.

For further information on how disinfectants affect pipe life and performance (or don’t in the case of McWane Ductile Iron Pipe), please contact one of our Sales Representatives, Regional Engineers, or Product Engineers.

Need Assistance with Your Waterworks Project?

We have team members who’ve managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design, to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

Appendix:

- USEPA, “Understanding Disinfection Residuals”

- USEPA, “The Effectiveness of Disinfectant Residuals in the Distribution System”

- TCEQ, “Disinfectant Residual Reporting for Public Water Systems” Dear, J. P. and Mason, N.S., “The Effects of Chlorine Depletion of Antioxidants in Polyethylene,” Polymers and Polymer Composites, Vol 9, No. 1, 2001.

- Duvall, D. and Edwards, D., “Oxidative Degradation of High-Density Polyethylene Pipes from Exposure to Drinking Water Disinfectants,” Engineering Systems Inc., December 18, 2009.

- “Is PE resistant to the chemicals commonly used for disinfection, e.g. chlorine?”, PE100+ Association, May 29, 2018, Online Article, accessed March 10, 2020.

- Colin, X., et al, “Aging of Polyethylene Pipes Transporting Drinking Water Disinfected by Chlorine Dioxide. Part II – Lifetime Prediction,” Polymer Engineering and Science, 2009.

- Jerry Eng, Thomas Sassi, Thomas Steele, Giacomo Vita, Cytec Industries, “The Effects of Chlorinated Water on Polyethylene Pipes”

- Susan M.Mitroka, Timothy D. Smiley, J.M. Tanko, Andrea M.Dietrich, “Reaction mechanism for oxidation and degradation of high-density polyethylene in chlorinated water”