One can look around any job site in the nation, no matter the location, scope of work, or scale of the project where the Ductile iron pipe (DI pipe) is being installed, and notice one common factor: some sort of pipe lubrication. Although commonly overlooked at these job sites and locations, pipe lube plays one of the most vital roles in the efficient installation of DI pipe. All types of DI joints require it, including above-ground, below-ground, and even underwater. Whether that may be a Tyton® Joint, Mechanical Joint, TR-Flex®, or Ball & Socket River Crossing pipe, all of these must have a type of lubrication in order to be properly assembled and installed. In this Iron Strong Blog, we will focus on why using the recommended pipe lube supplied by the DI manufacturer is so important.

Why Use Pipe Lubricant?

Pipe lubrication is required to minimize friction on the gasket when assembling the Ductile iron pipe pieces. For push-on style joint pipe, the lubrication allows the spigot to slide more easily into the adjoining bell while compressing the gasket and reducing the chance of rolling or cutting gaskets during the homing of the pipe. It is also important to note that with push-on DI pipe joints, keeping the lube off the underside of the gasket and seat of the bell is imperative. Friction in these locations between the metal gasket cavity and the rubber gasket is essential to a successful assembly.

Why Use Manufacturer-Recommended Pipe Lubricant?

Contrary to popular belief, too much pipe lubrication is a myth; when installing Ductile iron pipe, there is no such thing as too much lube. Although you cannot use too much pipe lube, one can, in fact, use the wrong pipe lube. All DI pipe manufacturers, as well as PVC pipe manufacturers, have their specific recommended pipe lubricant; more often than not, they are supplied complimentary with each shipment of pipe to their new homes.

For instance, the two lubes provided by McWane Ductile designed specifically for use with our pipe and fittings are:

- Phoenix Pipe Joint Lubricant

- Black Swan Pipe Lube

- We also supply a specialty pipe lubrication for Subaqueous Applications called NO-OX-ID .

These three lubricants have been designated as McWane Ductile’s recommended lubricants based on the productive interaction between the iron, the factory-applied seal coat, the factory-provided gasket, and the lube itself.

Pipe Lubricant Testing Standards & Applications:

Importantly, our pipe lubricants are a non-toxic, water-soluble material, not conveying either taste or odor to the water flowing through our Ductile iron pipe. These lubricants can prevent bacteria from growing and are suitable for hot and cold weather applications. Both lubricants provided by McWane Ductile are certified to meet NSF/ANSI Standard 61 for both potable water pipelines, drain waste and vent applications, as well as sewer systems. NSF/ANSI 61 standard is a national standard related to water treatment. This specific standard establishes and regulates stringent requirements for controlling equipment that comes into contact with potable water or products that support potable water production.

These pipe lubricants are manufactured without petroleum to avoid gasket degradation once the lube is applied. Lubricants utilize environmentally friendly raw materials found in everyday household items, most commonly soap.

Regarding the application of pipe lubrication, the Ductile Iron Pipe Research Association (DIPRA) states: "Apply lubricant to the exposed surface of the gasket and plain end of the pipe or fitting in accordance with the pipe manufacturer's recommendations. Do not apply lubricant to the bell socket or the gasket's surface in contact with the bell socket. Lubricant is furnished in sterile containers, and pipe installers should make every effort to keep it sterile.

IMPORTANT NOTE: With any style of push-on Ductile iron pipe joints, the one place one never wants to apply the lube is on the UNDERSIDE of the gasket. Friction between the metal gasket cavity and the rubber gasket is essential to a successful assembly. Lube in this area will ultimately prevent these frictions from happening. Lubrication for (MJ) Mechanical Joint assemblies is different, as will be explained later in this article.

Tips for applying DI Pipe lubricants:

- Do not alter the consistency.

- If liquid appears on the surface, simply mix well before using.

- Clean pipe and gasket surfaces thoroughly.

- Make sure the gasket is properly seated.

- There is no such thing as using "too much lube," especially with restraining gaskets.

- Apply pipe lube using a CLEAN sponge, cloth, glove, or brush.

- Be sure to apply it evenly and completely over the entire gasket surface.

- Do not place lubricant in the ring groove.

- For a Mechanical Joint gasket, it is best to lubricate it fully BEFORE sliding it onto the spigot end.

PRO INSTALLATION TIP: For mechanical joints, be they pipe bells, fittings, valves, or other appurtenances, a FULLY FRICTION-FREE gasket is the best approach. Friction is the enemy of the required movements and spreading of the gasket into its typically triangular recess. In fact, over many decades, a Mechanical Joint assembled DRY has been the number one cause of installation-related leaks in pipelines across the industry. A dry MJ assembly will lose significant sealing ability by the gasket through the slow friction release created during a dry assembly. For mechanical joint assemblies, generously lubricate all three sides of the gasket before placing it on the pipe spigot. It serves to make the assembly tighter and more equally compressive radially.

PRO SAFETY TIP: Similar to soap, prolonged contact with the skin could cause irritation. Keep lubricant from coming into contact with the eyes. In case of contact with eyes, flush with water for 5 minutes. If discomfort persists, get medical attention.

Conclusion

As stated earlier, it’s very easy to overlook the importance of Ductile iron pipe lube when assembling and installing your DI pipeline. Certain lubricants have been specifically formulated and designed to best suit certain pipe materials and their gaskets. Always be sure to use the lubricant provided by your pipe manufacturer, whatever material you choose. In addition, by following the recommended installation guidelines when installing DI pipe, you can take significant steps in ensuring an efficient and sustainable DI pipeline installation that will last for generations.

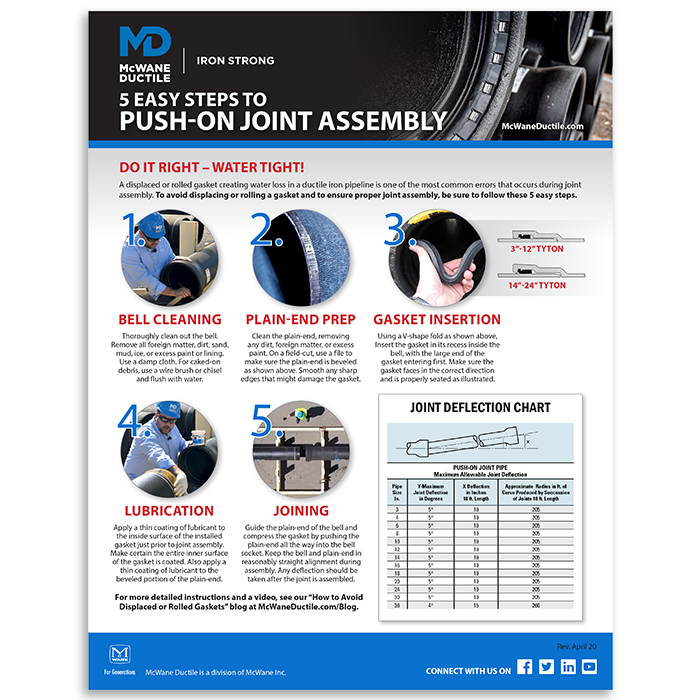

Avoid a displaced or rolled gasket by using our handy Push-On Joint Assembly Tip Sheet!

Need Assistance with Your Ductile Iron Pipeline Project?

If you have any questions regarding the use of above-ground, below-ground, or subaqueous lubricants for Ductile iron pipe installations, be sure to reach out to your local McWane Ductile Representative. We have team members in supportive roles, who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience with pipeline construction.