“Why should I use Ductile iron pipe?”

The question is ostensibly meant to include “instead of other types of piping material.” Well, the reasons are vast and vary depending on project requirements. Since we aren’t talking about a specific project, we’ll look at the general overriding reasons Ductile iron pipe (DI pipe) is the best choice for your piping projects.

First, ask yourself the following questions:

- Are you concerned with long-term pipe performance or how long your piping system will last?

- Do you care about the cost of operating your pipeline system?

- Are you concerned with the actual cost of the system over its entire life or its lifecycle cost?

- Do you care about the environment?

If you answered yes to any of these -- and as a utility or consulting engineer, you probably would -- then you have already answered that Ductile iron pipe is the right choice for you. Let’s look a little further into why this is so.

Are you concerned about long-term performance?

Who wouldn’t be when it comes to designing utility systems?

Ductile iron pipe can provide over 100 years of unrelenting, high-level performance! Proof of this performance is provided by more than 560 utilities throughout North America that have iron pipe still in service that are over 100 years old, as well as many over 150 years old. Additionally, iron pipe served the Fountains of Versailles, France for over 300 years.

Furthermore, the American Water Works Association’s (AWWA’s) publication “Buried No Longer: Confronting America’s Water Infrastructure Challenge” shows Ductile iron pipe not only outlasts any other piping material but is expected to last over 100 years throughout North America.

How can DI pipe be so durable? In viewing information on long-term performance, unlike other materials, DI pipe is not subject to weakness or degradation over time. Some materials suffer from what is known as “creep” and “stress regression” which cause those materials to degrade and lose strength over time.

These performance losses are often accelerated by changes in temperature, pressure, and other performance factors. DI pipe is not affected in this manner, assuring that the pipe you install today will be the pipe you rely on for decades to come.

Do you care about the cost of operating your pipeline system?

If you do, Ductile iron pipe will save you operating costs in several ways including pumping costs, tapping costs, and possible damage from other construction, causing failure and the cost to repair in general.

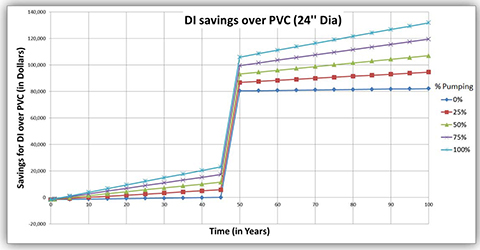

On pumping costs, DI pipe is more energy efficient than other competing pipeline materials due to its oversized inside diameter. This reduces the force needed to push water or other liquids through the pipe. This can be easily calculated using the Energy Savings Calculator on the McWane Ductile Pocket Engineer. Check out our informative blog titled Can Using Ductile Iron Pipe In Your Water System Save You Money On Your Electric Bill? which addresses using DI pipe in your water system to save you money on your electric bill.

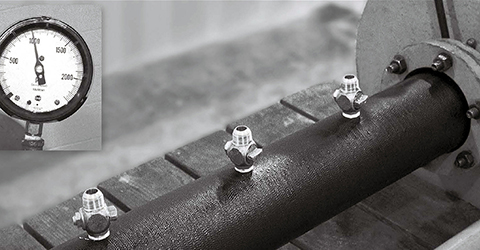

Tapping costs for services or future connections is done most economically and reliably on Ductile iron pipe because of the iron’s inherent strength. This strength allows services to be tapped and threaded directly into the pipe wall itself without the need for expensive saddles which require additional material and labor costs.

Additionally, DI pipe can be easily and quickly tapped with minimal equipment wear and tear due to the graphite content in the iron matrix.

Repairs to Ductile iron pipe are generally much easier to complete. When issues occur, they are typically point source repairs that can easily be remedied with the installation of a stainless steel repair clamp or a spool piece of pipe and a couple of restrained Mechanical Joint sleeves. These materials are usually readily available from local supply house yards. The advantage of using DI pipe in both repair cost and repair frequency is documented in a University of Michigan research report published in 2016.

Read “Modern McWane’s The 18-Inch Transmission Main Story,” where Bert Weiss, retired from the City of Hayward, attests to the availability of DI pipe which helped to turn what could have been a very bad day into an easy fix.

Are you concerned with the actual cost of the system over its entire life or its lifecycle cost?

As we now know, today’s cost of material can often be insignificant compared to the total cost of ownership over its life. We consider this lifecycle cost when we make purchasing decisions on everything from cars to appliances and electronics, to our homes.

When it comes to Ductile iron pipe, lifecycle cost is one of its greatest benefits. Since it lasts for generations, is economical to operate, and is easily and efficiently installed and operated, its long-term or lifecycle cost is easily lower than any other material. The earlier referenced University of Michigan also addresses pipe lifecycle cost.

If you would like to have an actual lifecycle cost analysis done for your project, one of McWane Ductile’s Regional Engineers can help you with those calculations.

Do you care about the environment?

When it comes to the environment, Ductile iron pipe is always the best choice. Ductile Iron Pipe is manufactured from up to 95 percent recycled scrap metal. It is easily recycled itself as it is not made from any toxic materials. Because of its manufacturing process as well as the production of its raw materials, DI pipe has a smaller carbon footprint than other materials.

Because of these attributes, DI pipe is the only pressure pipe available with SMaRT certification from the Institute for Market Transformation to Sustainability (MTS). MTS awarded DI pipe its Gold Level Certification. This means using Ductile iron pipe can contribute to your project’s score in earning Leadership in Energy and Environmental Design (LEED) or ENVISION certification.

To see how Ductile iron pipe from McWane Ductile can help you meet your environmental and sustainability goals contact one of our ENVISION Accredited Professionals.

Need assistance with your water infrastructure project?

These are just a few of the highlights of why you should use Ductile iron pipe for your piping needs. If you have any questions regarding your water or wastewater infrastructure project, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

References

American Water Works Association (AWWA) (2015). “Buried No Longer: Confronting America’s Water Infrastructure Challenge.”

Toxicity of Building Materials, Pacheco-Torgal, Jalali and Fucic

Design of Water Supply Pipe Networks, Swamee and Sharma

A Framework to Evaluate the Life Cycle Costs and Environmental Impacts of Water Pipelines, Thomas, Mantha, and Carol C. Menassa, University of Michigan

American Water Works Association (AWWA), and American National Standards Institute. (2007). “AWWA standard for polyvinyl chloride (PVC) pressure pipe and fabricated fittings, 4 in. through 12 in. (100 mm through 300 mm), for water transmission and distribution.” Denver, Colo: American Water Works Association.

Ductile Iron Pipe Research Association (2015). “GUIDELINES Installation Guide for Ductile Iron Pipe”, DIPRA

Ductile Iron Pipe Research Association, https://www.dipra.org/ductile-iron-pipe-resources/technical-publications/tapping

Ductile Iron Pipe Research Association, https://dipra.org/ductile-iron-pipe-resources/downloadable-brochures/celebrate-sustainable-infrastructure-brochure

The Institute for Market Transformation to Sustainability: http://mts.sustainableproducts.com/SMaRT_product_standard.html

PVC's Physical Properties (2014), (Sep 8, 2014)