The more than 75 years of ongoing research on iron pipe corrosion and the use of polyethylene encasement has led to this type of corrosion mediation becoming the accepted industry practice for protecting ductile iron pipe. So, the question many may ask is; “Since I had such success with standard polyethylene encasement, why should I now use V-Bio Polyethylene Encasement instead?” To best answer this, it’s imperative to look at what specifically V-Bio provides that is not available with standard polyethylene encasement.

Field Observation and Research Lead to Innovation

During the many years of research in highly-corrosive environments and real-world installations, changes to polyethylene encasement, based on both manufacturing and materials improvements, has resulted in ongoing product development.

Regularly monitored installations going back to Lafourche Parish’s 1958 installation of polyethylene encased pipe has shown the excellent performance of the earliest polyethylene encasement. Unfortunately, there have been some instances where polyethylene encasement has been damaged resulting in isolated pipe corrosion at the point of damage.

It was discovered that where excessive moisture was able to accumulate underneath the polyethylene encasement, isolated cases of an environment enabling the development of microbiologically induced corrosion (MIC) occurred. With this information from producers and users, these areas for potential improvement were identified.

DIPRA (Ductile Iron Pipe Research Association) has taken this feedback and incorporated it with its own research as well as research done by other corrosion experts to develop an enhanced version of polyethylene encasement known as V-Bio.

Product Markings and Identification of V-Bio® for Quality Assurance

V-Bio Enhanced Polyethylene Encasement provides a level of quality assurance not found in standard polyethylene encasement.

V-Bio is stenciled with markings indicating it is in fact V-Bio, made in accordance with AWWA/ANSI C-105/A21.5, a warning that any damage needs to be repaired, the manufacturer, what pipe size(s) the wrap will cover and DIPRA identification.

Standard polyethylene encasement does not carry all these markings. Without these, it makes the inspector’s and installer’s jobs harder as they do not readily know that the selected material meets standards and specifications.

Improved Manufacturing Provides a Stronger and More Durable Product

Because V-Bio is a coextruded, multi-layered film, it has a different exterior color and interior color. Bright white is standard for high visibility both during installation and in the event the wrapped pipe is disturbed. The bright white allows the black pipe surface to be more visible in the event the wrap is damaged.

Standard polyethylene encasement is typically clear or black placing a greater burden on installers and inspectors by their need to inspect more closely for damage and/or improper installation.

Note: To ensure that you are receiving true, V-Bio Polyethylene Encasement, purchase of this material is recommended through the DIPRA member companies.

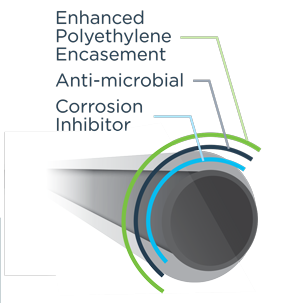

Because V-Bio is a three-layer coextruded film that has up to 50 percent greater physical strength than single layer polyethylene encasement giving V-Bio greater resistance to punctures and tears. Unlike standard polyethylene encasement or any other corrosion protection system, V-Bio polyethylene encasement contains a corrosion inhibitor and a biocide.

- The corrosion inhibitor helps protect the underlying iron in the event there is small or minor undetected tears or punctures.

- The biocide kills bacteria thus preventing microbiological induced corrosion (MIC), another area of concern with standard polyethylene encasement.

This combination of superior material and technology work to provide excellent corrosion mitigation in most soils and installation environments.

Price Considerations When Using V-Bio® Versus Other Polyethylene Encasements

So now that we know what the primary differences are and why they make V-Bio the best choice for corrosion protection of McWane Ductile iron pipe, the question becomes; how much is this going to cost?

You might hear from V-Bio detractors that it costs twice as much as standard polyethylene tubing, but this does not mean a V-Bio protected installation is twice the cost of a standard polyethylene encased installation or even an unprotected installation. Obviously, V-Bio costs more than standard polyethylene encasement, but this needs to be put into proper perspective.

As we discussed in our prior blog, Why Use Ductile Iron Pipe? Four Key Considerations, pipeline construction can cost several hundred to several thousand dollars per foot. Just supposing V-Bio is twice the cost of standard polyethylene encasement, at $1.00/ft it represents less than 5/100ths of one percent to ¼ of one percent of the project cost.

If amortized over the 100-plus years of the pipe’s expected life, you’re looking at somewhere around $0.01 per ft, per year, or about $53 per mile of pipeline per year, which is substantially less than even the cost of time thinking about that pipe or even reading this blog.

Considering all the above, using V-Bio instead of standard polyethylene is such an easy decision that it doesn’t even require any further thought.

For more information about V-Bio, corrosion protection of McWane Ductile iron pipe or other questions, please contact one of our NACE (National Association of Corrosion Engineers) Certified Engineers. Also, please check out an excellent piece on the proper installation of the product in our blog, Eight Steps for Installing V-Bio Polywrap.

Need assistance with your water infrastructure project?

McWane Ductile offers multiple services for our customers extending far beyond manufacturing ductile iron pipe. From design to installation, we take great pride in providing education and assistance to water professionals throughout the water and waste water industry.

Check out all our digital offerings:

References

AWWA C-105, Polyethylene Encasement for Ductile Iron Pipe

CORRPR0, “Ductile Iron Pipe V-Bio ® Enhanced Polyethylene Encasement and Zinc Metalizing – Corrosion Control Research Project Report”

“Bonded Coatings vs Polyethylene Encasement”

RICHARD W. BONDS, LYLE M. BARNARD, A. MICHAEL HORTON, AND GENE L. OLIVER, “Corrosion and corrosion control of iron pipe: 75 years of research”