McWane Ductile is committed to offering educational resources based upon sound engineering data to our clients and potential clients. One of these resources includes banners that display certain information about our product.

While attending a recent conference, we were challenged on the information these banners contained. In fact, one unknown individual walked by the booth and shouted, “Lies... that information is lies!” without the courtesy of stopping to discuss why he felt that way or what exactly was his objection.

In this article, we will detail the information used to build the banners for Ductile Iron Pipe Costs Less, Ductile Iron Pipe is Stronger, and Ductile Iron Pipe is Safer than other pipeline materials.

Ductile Iron Pipe Does COST LESS

So how is it that we can say Ductile iron pipe (DI pipe) “Costs Less” on one of our banners? Well, let’s begin with the hydraulic efficiency of DI pipe in relationship to other pipeline materials.

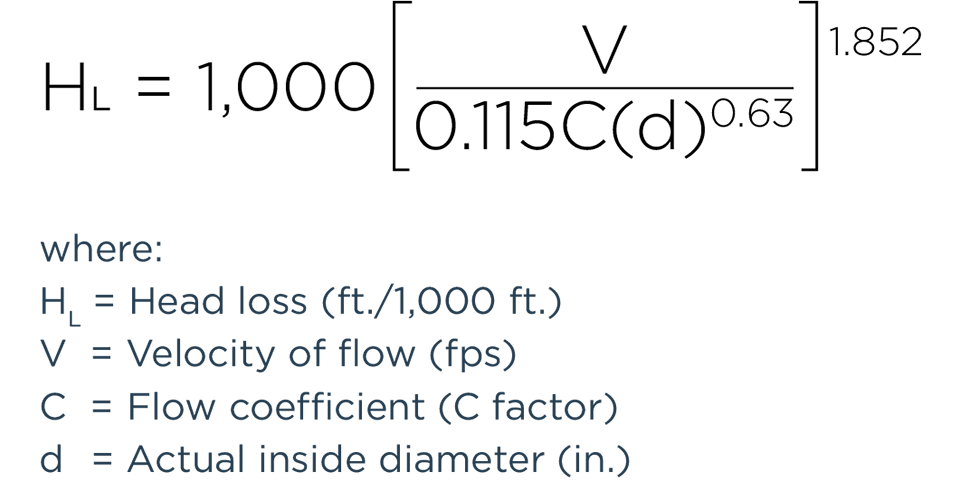

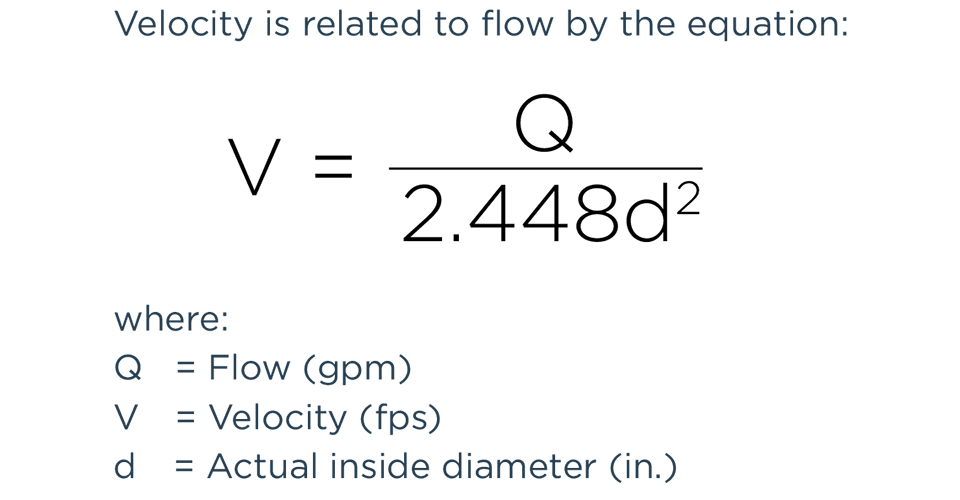

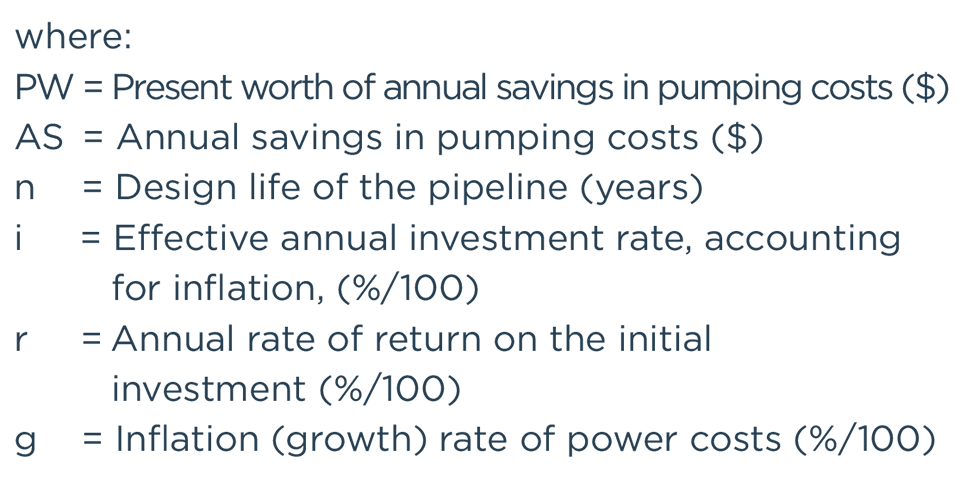

Although there are several engineering equations that can measure head loss, one of the most commonly used is the Hazen-Williams Formula:

You’ll note the actual inside diameter is an essential factor in this equation ─ the larger the diameter ─ the smaller the head loss experienced.

In order to provide sufficient flows to various parts of a water system, energy must be applied to move the water within the pipeline. In many cases, this energy is first supplied by pumps at the treatment plant and most likely supplied by booster pumps to get water to customers with sufficient pressure and flow.

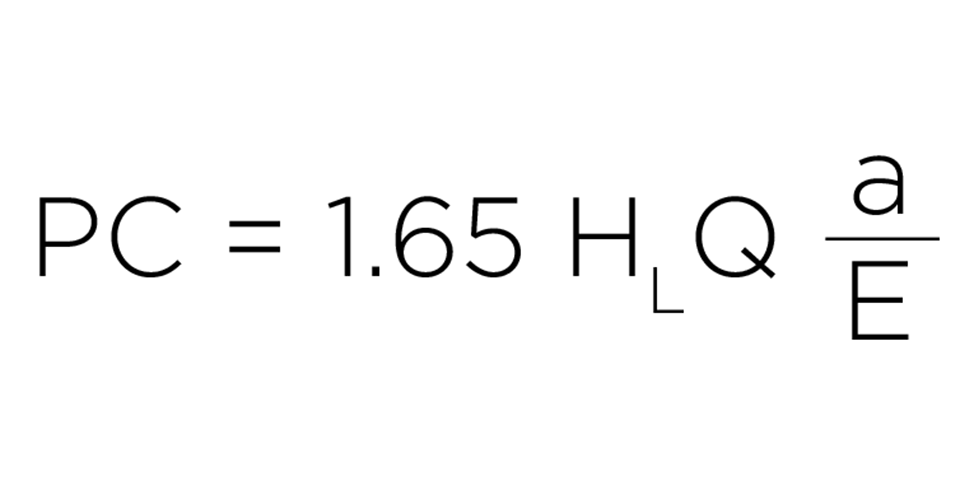

The more significant the head loss ─ the more energy required. Subsequently, the smaller the head loss ─ the less energy required. The following equation represents this energy requirement as it relates to head loss:

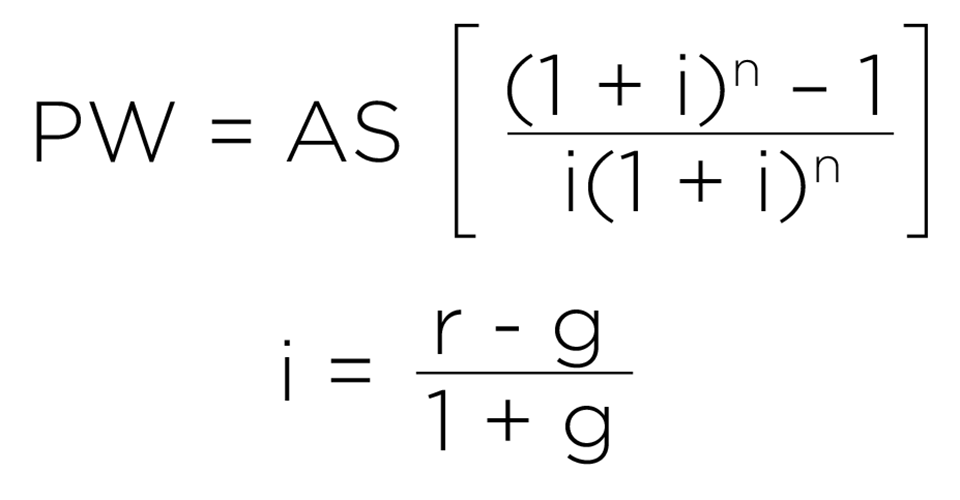

We see from the equation above that a utility should experience lower pumping costs, thus lower electric bills when using pipeline material with a larger inside diameter. So, what are the cost savings to the utility over the life of the pipeline segment just installed? The following formula can determine these savings:

Once the value is obtained by using the equation above for one segment of pipeline installed, one can extrapolate these values respectively to pipes within the system with like variables to determine savings to the entire water system over the life cycle of the pipeline material. So that I might illustrate the use of the engineering approach to this cost savings, let’s take the following hypothetical example:

- 24-inch DI pipe vs. 24-inch Polyvinyl Chloride (PVC) Pipe

- Pipeline Length: 30,000 ft.

- C Factor: 140 for DI 150 for PVC

- Flow Rate: 6,000 GPM

- Unit Power Cost: 0.10 $/kWh

- Pump Rate: 24 Hr/Day

- Pump Efficiency: 70%

- Design Life: 100 Years

- Rate of Return: 5%

- Inflation Rate: 3%

Because 24-inch DI pipe (class 200) has a larger inside diameter than 24-inch PVC pipe (DR 18), the annual savings to the utility under the assumptions listed above would be $1,213,307 over the design life of this one segment of pipe. Cost savings using DI pipe vs. CCP/steel and HDPE (DR 11) respectively, would equate to $672,178 and $3,208,741 under the same conditions listed above.

It should be noted this inside diameter differential contributes much more substantially to head loss than C-factors, and field tests have proven the C-factor in cement-lined DI pipe does NOT appreciably decrease over time. For even more information and a helpful video, see my colleague’s blog about saving energy on your electric bill by using DI pipe by Jon Melloan.

Another attribute of DI pipe noted on the “Costs Less” banner refers to DI pipe lasting twice as long as PVC pipe. This statement is derived from a research report authored by the American Water Works Association entitled “Buried No Longer.” Although the basis of this report was to identify the state of water infrastructure within the U.S. at that time, the report contained charts giving estimated service life of different pipeline materials by size and region of the country.

When reviewing this information, DI pipe has an estimated service life of nearly twice that of PVC in many regions of the country, in many sizes. This estimated service life data wherein DI pipe lasts twice as long as PVC was further validated in a report entitled A Framework to Evaluate Life Cycle Costs and Environmental Impacts of Water Pipelines authored by the University of Michigan.

How does this extended asset life of DI pipe benefit the utility?

Obviously, if an asset needs replaced while another asset continues to provide service, the capital needs of the utility will escalate replacing shorter-term assets, thus requiring a higher cost to the customer.

DI pipe is produced from more than 95 percent recycled material. This fact is coupled with the embodied energy, as evidenced in the production and operation of DI pipelines being half that of PVC. This recyclability, identified in the previously mentioned University of Michigan research, substantiates DI pipe as being an environmentally friendly material with a lesser carbon footprint than PVC. Because the use of recycled material by DI pipe manufacturers requires significant volumes, inherently municipal and regional recycling programs reap the benefits.

Ductile Iron Pipe is IRON STRONG

DI pipe Has Up To 13 Times More Strength Than Plastic Pipe.

Impact strength is an essential characteristic of piping materials. While this property relates more to conditions the pipe might encounter during handling, shipping, and installation, it is nevertheless crucial because damage incurred during these activities can go undetected and later result in failures in the operating pipeline.

Tests were performed on Ductile Iron and PVC utilizing both the IZOD (cantilevered beam) and Charpy (simple beam) methods at 73.4 degrees F, Minimum Specified Values per Applicable Standards (AWWA C151 and AWWA C900). The results were the following measurements:

- Minimum Specified Values: Ductile Iron-17.50 ft-lbs per inch; PVC-0.65 ft-lbs per inch

- Charpy Test: Ductile Iron-27.6 ft-lbs per inch; PVC-1.42 ft-lbs per inch

- IZOD Test: Ductile Iron-16.6 ft-lbs per inch; PVC-1.25 ft-lbs per inch.

Therefore, taking the test data above utilizing the IZOD method, dividing 16.6 ft-lbs/in by 1.25 ft-lbs/in, this calculation demonstrates that DI pipe has 13 times the impact strength of PVC.

Plastic Pipe Becomes Brittle in the Cold and Weak in the Heat

In accordance with the AWWA Manual on PVC Pipe-Design and Installation (M-23), “The performance of PVC pipe is significantly related to its operating temperature.” The manual notes specifically that “PVC pipe loses impact strength and becomes less ductile as temperature decreases, necessitating greater handling care in sub-zero weather.”

The manual notes additionally that “with the increase in temperature, PVC pipe loses tensile strength and stiffness; consequently, the pressure capacity of the pipe is reduced, and more care is necessary during installation to avoid excessive deflection.”

PVC pipe is rated for performance characteristics at 73.4 degrees F. Figure 1-2 in the M-23 Manual (Second Edition) highlights strength characteristics for PVC pipe versus temperature.

Conversely, these temperature variations do not affect the strength properties of DI pipe.

Plastic Pipe Can Lose More Than One-Third of Its Strength from Sun Exposure Prior to Installation

A publication entitled “The Effects of Ultraviolet Radiation on PVC Pipe” (UNI-TR-5-03) developed by the Uni-Bell PVC Pipe Association states on page 10 of the report: “However, the lowest single average impact strength reported throughout the entire evaluation period was 139 ft-lbf following 15 months of exposure. The 139ft-lbf value represents 66 percent of the ASTM initial value.”

Therefore, testing performed by the PVC industry on its own product substantiates plastic pipe can lose more than one-third of its strength from sun exposure before installation. Extended sun exposure does not affect the strength properties of DI pipe.

Ductile Iron Pipe is SAFER

- A scratch the thickness of a dime can compromise the entire length of plastic pipe, resulting in leaks and compromised water purity.

Improper handling of PVC pipe can lead to impact damage, scratching, or gouging of the pipe wall. If such handling results in a scratch or gouge that is more than 10 percent of the wall thickness, ANSI/AWWA C605-94 (Section2.13) recommends the rejection of the damaged pipe upon delivery. If the damage occurs during installation, the damaged section should be cut and removed from the rest of the pipe.

On an 8-inch DR 18 PVC pipe, a 10 percent scratch (0.05-inch) is approximately the thickness of a dime. Recommendations are that the inspector on a PVC pipe job be equipped with the proper gauge to measure such damage as might occur when the pipe is handled and installed.

Obviously, leaks in a water system can potentially affect water purity parameters by lowering system pressures below acceptable levels or providing for potential contamination during the leak repair process.

It should also be noted that such gouging of the pipe wall using PVC in trenchless installation applications such as Horizontal Directional Drilling or Pipe Bursting creates additional concerns regarding hidden weaknesses on the pipe surface. Conversely, DI pipe has no measurable loss of strength due to normal handling or when used in trenchless installations.

See another informative blog on how quality and safety standards are ensured during the production of Ductile iron pipe by McWane Ductile Product Engineer, Jerry Regula.

- DIP is cast safely with green recycled iron and steel, while plastic pipe is made from petrochemicals that can be harmful to the environment and human health.

- Plastic pipe releases dangerous chemicals during production.

DI pipe, the durable and environmentally friendly choice for water utilities around the world, earned a coveted GOLD Rating as a sustainable product by the Institute for Market Transformation to Sustainability’s (MTS ) SMaRT certification. As the clear and superior choice for sustainable water and wastewater infrastructure investments, DI pipe is also only the second product in the buried infrastructure industry to earn this certification.

Having as much as 98 percent recycled content, DI pipe is itself a 100 percent recyclable material. DI pipe is durable and dependable in all environments. The certification also recognizes Ductile Iron Pipe Research Association (DIPRA) member companies and their commitment to ensuring the health and safety of employees and the public by working to prevent injury, illness, and pollution. DIPRA member companies strive to ensure their operations do not negatively impact the surrounding environment or the safety of workers.

Conversely, PVC pipe is produced from petroleum derivatives, chlorine gas, and vinyl chloride, the latter two substances being of concern in environmental circles. Green Living Tips, a website which fosters sustainable living advice, posts the following information concerning PVC:

- For starters, oil and chlorine aren’t what you’d call “green” substances regarding their extraction, refining, and by-products.

- Greenpeace has pushed for the cessation of PVC production as dioxin is created from the manufacture and incineration of the substance.

- Currently, only one percent of PVC is recycled due to the difficulty in recycling due to the presence of additives.

- Click here to learn more about the importance of recycled content in DI pipe by McWane Ductile Sales Operations Manager, Stuart Liddell.

Many folks in our industry understand the value DI pipe brings to water infrastructure. In a recent interview with Bill Dunnill, General Manager of Consolidated Utility District in Murfreesboro, Tennessee, Dunnill explains why he uses DI pipe. Read more here.

You Ask, We Answer

At McWane Ductile, we are committed to offering educational resources based upon sound engineering data, as shown here. You just can’t make this stuff up…as one might in the game of Fact or Fiction. Simply put, Ductile iron pipe is safer, stronger, and costs less.

If you have any questions regarding this blog, please feel free to contact your local McWane Ductile representative. We go far beyond just manufacturing Ductile iron pipe and we would be happy to assist. We also offer on-site classroom or job-site training for you and your colleagues.

Check out all our digital offerings: