At McWane Ductile, we are proud to manufacture the strongest, most durable, and most flexible piping material available to the waterworks industry. Even with these great attributes, we still take great care when handling Ductile iron pipe (DI pipe). In this Iron Strong Blog, we’ll cover some key tips to safely handling your DI pipe once it arrives at your job site and throughout the construction or your pipeline project.

Back at our foundries, we produce hundreds of sticks of DI pipe daily. Once the pipe is cast, annealed, tested, lined, and painted, it is bundled and secured on timbers with blocks and straps. It is then safely loaded onto a truck for shipment to your job site. See the video below that covers how many pipe can ship at one time by Martin Rodriguez.

Think Safety First

Prior to pipe arrival, it is important to select a good lay-down area for where the pipe will be unloaded and stored. Some essential safety tips to consider include:

- Determine a safe location free from traffic hazards.

- Keep in mind, the truck and trailer need ample room to maneuver.

- The unloading area should be level to help maintain the stability of the truck and trailer. The ground should be free of potholes and debris.

- Look up and look around. The unloading area should be clear of overhead electric lines. Coming into contact with a power line can be dangerous – even deadly.

- The unloading area should be clear of foot traffic from pedestrians or other employees not involved in the loading/unloading process.

- The unloading area should have enough lighting for early morning or evening loading or unloading.

Before Removing Pipe From the Trailer

- Be sure you have the proper equipment on-hand to handle the pipe's weight and safely unload the pipe. See this helpful Iron Strong Blog by my colleague, Gary Gula, on the importance of knowing the weight of DI pipe.

- Carefully inspect any bands or straps securing the pipe, as they may have come loose during transit.

- Inspect the entire load for any missing blocks or shifting of the bundles during transit before unloading.

- Ensure you have received the correct product(s). Verify your quantities, the type of pipe, the pipe's size, gaskets, and lube.

- Check for any damage to the product and ensure you have all the necessary paperwork.

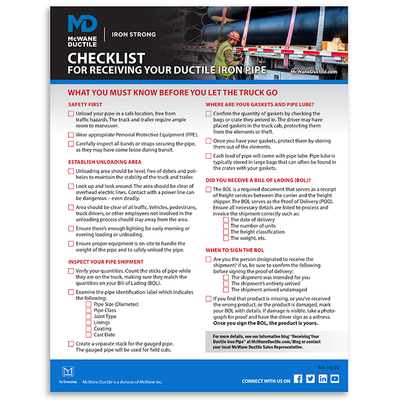

For more great tips on what you must know before you let that truck go, see this Iron Strong Blog with a handy tip sheet by my colleague, Josh Baker.

Unloading Your Pipe Safely

Now let’s talk about how to unload and handle your pipe safely.

- Once it is determined that the load looks good, remove the bindings, either nylon straps or chains, that secure the trailer's bundles.

- Always make sure that no person is standing on or near the trailer while the materials are unloaded.

- Cut the straps that join the bundle.

- Never unload pipe by rolling it off the trailer. Rolling can damage the pipe and can be dangerous for anyone standing nearby.

- Only pick up as many pieces of pipe with forks of a loader as deemed safe and reasonable.

Before you let that truck full of Ductile iron pipe go, be sure to follow the guidelines on this free and handy checklist!

DOWNLOAD NOW

Storing Pipe on the Job-site

Once the pipe is unloaded, it can either be re-stacked or strung out along the ground.

- If pipe is re-stacked, make sure the wood blocks are still attached to the timbers that came with the load.

- Replace any missing blocks to prevent pipe from shifting when stacked.

- When stacking pipe, many variables should be considered including ground type, anticipated ground conditions if weather changes, size and class of pipe, and the safe reach and balance (counterweight value) of the machinery being used.

See the chart below from the Ductile Iron Pipe Research Association's Installation Guide for Ductile Iron Pipe for recommended heights for stacking DI pipe.

Cold Weather Tip:

Installers are a tough bunch and do not always stop production due to a little rain or snow. Extra care must be demonstrated during the installation of any product during these conditions. Wet or frost-covered materials of any kind can be slippery.

Lifting Your Pipe Safely During Installation

Once it is time to start installing pipe in the trench, what should you use to pick up the pipe? Common types of devices are:

- Nylon Straps – These are widely utilized because they have less potential to shift and typically do not damage pipe coating. Caution must be taken to determine that the nylon strap used is rated for the pipe weight it will be supporting. Larger diameter pipe weigh more than smaller pipe and require higher-rated straps. Straps should also be inspected periodically for wear and replaced when worn.

- Steel Cables – These are also commonly used but are most likely to cause damage to the coating. Steel Cables will most definitely cause damage to polywrap if placed over it. These should also be inspected periodically and replaced when worn.

- Note: Pipe with polywrap should never be picked up with strapping coming into direct contact with the polywrap, regardless of lifting device, but especially with a steel cable.

- Pipe Tongs – These are specifically made for lifting pipe and are available in different diameter ranges. Most of these commonly utilize a scissor action with actuators to secure the pipe. These tend to be more expensive than other alternatives, and several would be needed to cover a vast range of pipe diameters. It is also recommended that the inside of the tongs be lined with rubber to protect the pipe.

Some More Pro Tips When Handling Ductile Iron Pipe

- Pipe should never be moved or installed by placing a fork inside of the pipe. Lifting with a fork has a high potential of damaging the cement lining inside the pipe. Using a fork should also never be done to raise fittings or any other appurtenances.

- Never stand directly under a pipe that is being lifted into the trench. Try to stay as far away as possible in case of a break or slipping with the lifting device.

- When the pipe is in the trench and the lifting device is removed, it is recommended to use a wood block placed between the bell's face on the pipe and the machine's bucket.

- You should always avoid pushing on the bell directly with the bucket.

- Additional installation instructions are available in the ANSI/AWWA C600 Installation of Ductile Iron Mains And Their Appurtenances.

Handling Ductile Iron Pipe During Special Applications

Special installations such as a bridge, river crossing, or horizontal directional drill projects are all unique and must be addressed accordingly. Evaluation of the project prior to installation is recommended. Here are some more helpful Iron Strong Blogs on special applications:

Did You Know?

Every load of McWane Ductile pipe comes with Material Safety Data Sheets (MSDS). The MSDS is inside the packet of paperwork that typically includes information on safety cautions, pipe lube, coatings, and installation instructions.

If you need job site assistance, have any questions regarding handling your Ductile iron pipe, or any other DI pipe related inquiries, please contact your local McWane Ductile Representative. We’re here to help. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry. As always: “Work Hard, Work Smart, and Work Safe!”