Most people commonly think the answer to this question is relatively simple. “All I need to do is make sure the Inside Diameter of the casing pipe is larger than the Outside Diameter of my carrier pipe.” While that is a correct answer, it isn’t necessarily the best answer. Within this Iron Strong Blog, we will closely examine what you need to consider when selecting a casing pipe to fit your application.

Let’s examine our selection criteria a little closer…

As mentioned, yes, it would be correct to state you need a casing pipe with a larger inside diameter than the largest outside diameter of the pipeline running through the casing pipe. That said, you need to take a closer look at the carrier pipe as well as any accessory items needed in order to determine what the largest outside diameter will be for the specific pipeline, then you can confidently select a casing pipe with a sufficient inside diameter to accommodate for the carrier pipe or pipes.

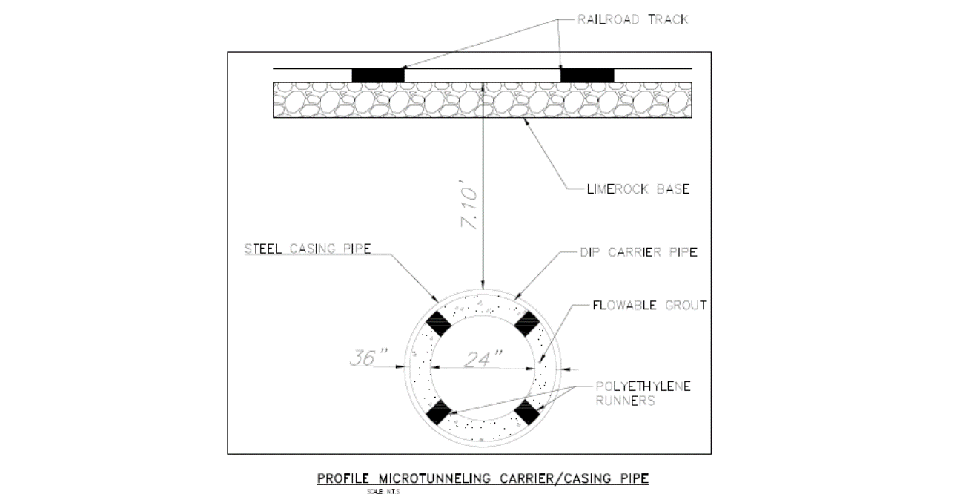

I mention pipe or pipes as it is possible to have more than one pipeline or conduit running through a single casing pipe, which will be illustrated later. For our example, we will be looking at 24-inch diameter Ductile iron pipe (DI pipe) as the carrier pipe throughout this blog.

Common Questions…

What type of pipe are you using?

Each size (diameter) of DI pipe will have the same outside diameter tolerances for the pipe barrel, regardless of the wall thickness being used. What will vary by size is the outside diameter of the specific bell, or joint type, being used.

The OD of the pipe's bell will always be greater than the OD of the barrel of the pipe. This variance is why it is essential to know the OD of the bell of the specific pipe joint being used. (Tyton Joint, TR Flex, Mechanical Joint, etc.)

This information is easily obtained by:

- Visiting the calculator tabulation within the McWane Pocket Engineer

- Our product brochure on our website

- Measuring by hand utilizing an OD Tape Measure

- Or contact your local pipe representative

For the sake of our example, you will see in the chart generated by the Pocket Engineer OD Calculator, that the outer diameters of the Tyton® Bell, MJ Bell, and TR Flex® Bell vary. These will require different OD and ID measurements for casing pipe that will accommodate those particular bell configurations.

What are Casing Spacers, and why do I need them?

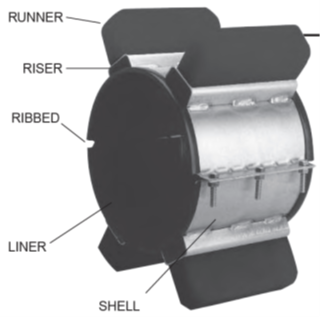

When utilizing a casing pipe with Ductile iron (or any material), you will typically be required to install what are called Casing Spacers or Polyethylene Runners on the outside of the barrel of the carrier pipe.

These spacers bolt together on the outside of the pipe's barrel and will need to be installed prior to the pipe being pulled through the casing pipe. The casing spacer will keep the carrier pipe in alignment within the casing pipe once it is pressurized and put into service.

You will need to verify with the spacer manufacturer what their recommended requirements are to ensure you install enough spacers per joint of pipe as well as the proper position along the barrel of the carrier pipe.

A casing spacer diagram is shown below, and a picture of them already installed on some DI pipe prior to installation. As you can see, It is a good idea to consider the added dimensions that the casing spacers may bring to your pipeline's overall outside diameter to ensure your casing pipe still has an adequate inside diameter to accommodate the spacers.

How do I know what type of Steel Casing pipe to use?

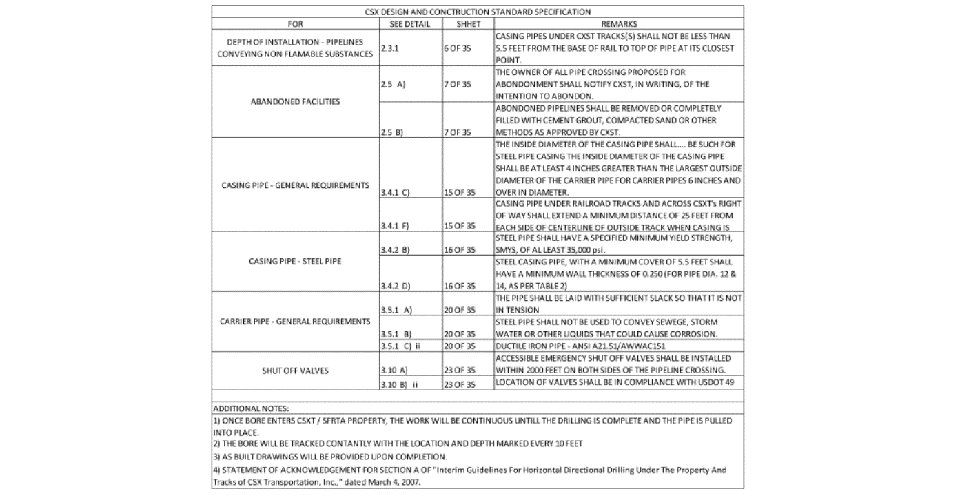

Steel casing pipes can vary in size and strength, so it is best to refer to the project specifications or local municipality specifications regarding exactly what type of steel casing pipe is to be used. As shown below, this information can vary but is typically easy to locate for your specific project.

It is recommended by CSX Railroad within their specification to utilize a casing pipe at least 2 inches greater than the largest outside diameter for conduits (pipe) that are less than 6 inches in diameter and at least 4 inches greater than the largest outside diameter for conduits (pipe) that are 6 inches or greater in diameter.

The chart below shows a CSX Railroad Design and Construction Standard Specification for casing pipe to be utilized under a railroad.

Similarly, the following chart shows a steel casing pipe specification similar to what you might find from your local municipality.

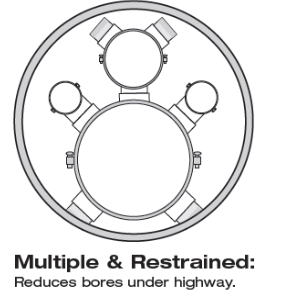

Can multiple carrier pipes be installed through a single casing pipe?

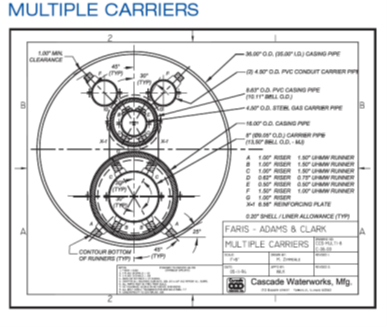

The answer is yes, that is possible. At times, you may encounter an application that requires more than one water or sewer line running through a single casing pipe or possibly a combination of utilities being run through a casing pipe including a conduit for some other application.

This is all possible. Below are a few examples of how it can be done. Essentially when facing an application such as described, it would be best to consult the manufacturers of the various products to ensure your installation plan would work properly.

Can casing spacers be used with a carrier pipe that is wrapped in Polywrap?

The answer to this is yes. When properly installed on a pipe that is encased in polywrap, casing spacers will still perform their duty regarding keeping the pipeline in place within the casing pipe once installed.

Should I push or pull my pipeline through a casing pipe?

It is always recommended to pull the pipeline through a casing pipe. Pulling will allow for full extension of the joints and also for a much easier installation. As I was once told, "think of your pipeline as a chain." Would it be easier to push a chain through the casing pipe or pull it through the casing pipe?

In conclusion

As the old saying goes, "Measure twice, cut once!" Although we are not necessarily cutting anything within this topic, you can now see the answer to our original question is a bit more detailed than you might have expected.

That said, below are a few photographs of various casing pipe applications that would not have gone very well if it were later discovered that the intended carrier pipe, spacers, etc. did not fit through the intended casing pipe. Aside from creating a real bad day for yourself, you would also be facing thousands of dollars to correct your mistake.

As always, McWane Ductile and our staff are here to assist you with all your Ductile iron pipe needs. Feel free to contact your local McWane Ductile sales representative directly with any questions regarding the use of casing pipe with Ductile iron pipe.

Check Out All Our Digital Offerings

- More articles and videos from our Iron Strong Blog

- Training Opportunities with McWane Ductile

- The McWane Pocket Engineer

- Engage with us on LinkedIn

- Follow us on Facebook

- Follow us on Twitter

References

McWane Ductile, https://www.mcwaneductile.com/

McWane Pocket Engineer, https://pe.mcwane.com/

Cascade Waterworks Mfg, http://www.cascademfg.com/

CSX Design & Construction Standard Specifications, https://www.csx.com/index.cfm/library/files/customers/property-real-estate/permitting/pipeline-design-construction-specifications/

Orlando Utilities Commission, https://www.ouc.com/business/water-services/manuals-reports