Utility pipelines provide for some of the most basic needs within our society. Essential services, such as supplying potable drinking water to our homes and businesses or sending wastewater away, are possible because of a network of buried pipelines. Whatever pipeline materials are used, they are expected to meet minimum service qualities such as withstanding leakage. This resiliency to leakage eliminates waste of our precious drinking water and prevents polluted soils from wastewater in the pipeline's proximity.

The service life of the pipeline can be ensured with a thorough understanding of and designing for:

- the loads to which a buried pipe will be exposed.

- its response to the loading.

- the interaction between the pipe and surrounding soils.

Proper backfilling is essential for safeguarding the pipeline against the internal and external stresses it experiences during its service life. If the backfill is constructed improperly during the pipe installation process, it can lead to premature maintenance and replacement of the pipeline.

Insufficient or inadequate backfill for any pipeline; whether the backfill is native soils or not, and regardless of the pipeline material used, will adversely affect the pipeline. This article will address the proper way to backfill around a Ductile iron pipeline and show that not all pipe materials' backfilling requirements are the same.

Pipe Functions / Flexible Conduit

A pipeline has two functions:

- It needs to be a conduit that allows a liquid to flow through it, whether by gravity or pressurized.

- It needs to be a structure to withstand both the internal pressure, if pressurized, external pressure from the height of the backfill material, and any surface/vehicle loading.

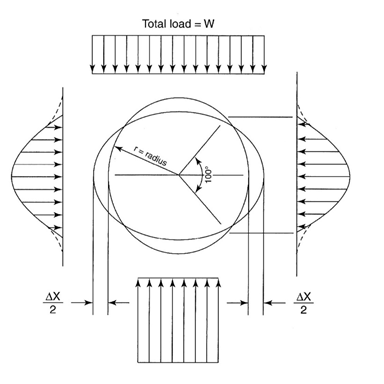

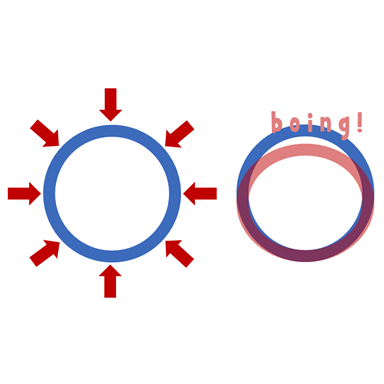

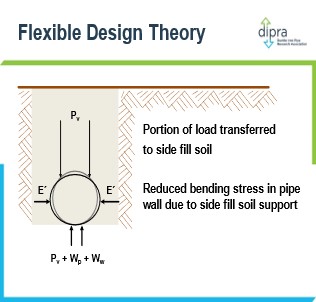

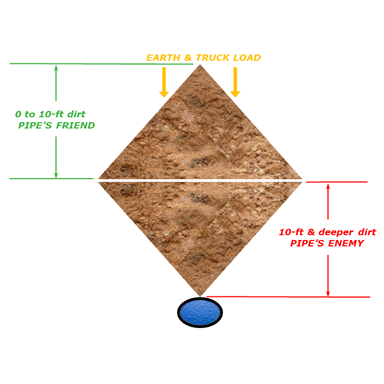

Ductile iron pipe (DI pipe) is considered a flexible conduit like all other pipe materials in our industry apart from reinforced concrete pipe. It is designed to deflect slightly as external loading is applied to the pipe. This is called the "Flexible Conduit Theory." A portion of the external loading is transferred to the pipe's surrounding side soils, which will reduce the bending stress and pipe deflection. Please see the diagram below.

The Flexible Conduit Theory is based upon the reliable and predictable relationship between stress and strain upon a known material, and the reactions such invokes. For a buried pipeline, this elasticity vs. reaction dance occurs between the pipe and the surrounding soils, sharing the loads while also controlling changes in the shape of the pipe, i.e. barrel deflections. Acceptable barrel deflections generally vary from 2% to 6% depending on the pipe material utilized.

The required support from the trench zone soils the pipe installer must achieve to keep the pipe from over-deflecting is called E', Modulus of Soil Reaction. See the diagram above. The required modulus of soil reaction E’ will vary depending on the pipe material involved and the depth of bury. The installer must compact the pipe backfill material sufficiently to achieve indicated E’ values.

Referring to the two pipe functions mentioned earlier, when the pipe is delivered to a project, all pipe materials must satisfy the conduit requirement; however, the installer of the pipe must build the backfill around the pipe to ensure the pipe performs properly as a cooperative structure. This is where Ductile iron pipe has distinct advantages over other materials.

Ductile Iron Pipe Advantages

First, Ductile iron is inherently much stronger than other pipe materials with a 60,000 psi tensile strength. The higher tensile strength allows the pipe walls to be thinner than other pipe materials, providing Ductile iron pipe with a much larger inside diameter, thus creating both hydraulic and energy consumption advantages for pressurized pipes. Please see McWane Ductile’s previous article “Can Using Ductile Iron Pipe in Your Water System Save You Money on Your Electric Bill,” by John Malone, 2018.

Second, Ductile iron’s pipe strength allows it to be less dependent on the pipe installer to provide the necessary strength from the pipe backfill to handle the external loading on the pipe. In fact, Ductile iron pipe allows native material to be used as backfill material around the pipe, providing the native material is suitable to provide the minimum acceptable compaction.

This strength can save significant time, expense, and carbon emissions versus transporting proper backfill materials to a job site for other pipe materials. In fact, Ductile iron pipe is so durable it offers five different trench types that address various backfilling requirements and applications. Trench types are standardized descriptions of how the pipe trench and backfill should be constructed. Please see the diagram below.

Type I trench is a flat-bottom trench with loose backfill and is the most economical of all the trench types. Type 5 trench is a pipe bedded in compacted granular material to the centerline of pipe and compacted granular or select material to the top of the pipe. (Approximately 90 percent Standard Proctor, AASSHTO T-99).

"Loose soil” or “select material” is defined as native soil excavated from the trench, free of rocks, foreign materials, and frozen earth. This trench type is common in deep bury, shallow cover, and larger pipe diameters. For more information on the different trench types, please see the previous McWane Ductile Iron article "Why is Depth of Cover Important When Installing Ductile Iron Pipe,” by Gary Gula 2019.

Proper backfilling is one of the most critical phases of pipeline construction. Backfill material is intended for filling the pipe trench and providing the required strength to keep the pipe from deflecting from external loading. If proper installation is not achieved, the pipeline will continue to over-deflect over time from the constant external loading. This can lead to damage to the pipe walls to the point of cracking, splitting, leaking, and eventually failure.

The unfortunate aspect of improper pipeline installation is that the owner generally doesn’t notice it right away. It is much like a sunburn you got when you were younger. You really did not see much damage right away and didn’t think much about it. It was not until years later you could see the damage. It is imperative to ensure our limited resources in infrastructure are used wisely. I encourage anyone who owns or designs a pipeline to make certain proper installation details are followed.

Need Assistance with Your Waterworks Project?

If you have any questions regarding backfilling your pipeline or anything related to your water or wastewater infrastructure project, be sure to reach out to your local McWane Ductile representative. We have team members who've managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.