Exceeding Expectations

McWane Ductile facilities have been manufacturing iron pipe for more than 100 years. Although we are proud of our history, we are not content to rest on our laurels. In fact, we are consistently improving our product development and manufacturing processes.

A means for this continuous improvement exists in the form of our new Universal Test Facility, located on the premises of McWane Ductile-Ohio.

This state-of-the-art testing facility was conceptualized and designed during several think-tank events by a management-selected group of highly-experienced McWane Ductile employees, so the facility would be tailored to the varied needs of all while focusing on quality to the customers first and foremost.

In this facility, our products are tested to ensure compliance with various certification requirements such as UL, FM, NSF, and BNQ are maintained. This facility is staffed and operated daily by an experienced group of pipe and system professionals who approach their work with a much greater scope than just “is this good metal?”

There is a living, breathing, interactive component to a pipeline far beyond “does the material meet standards,” although that is the first thing that is always checked in this facility

Product Development

At McWane Ductile, we are consistently looking to improve and extend our product line to meet the demands of a world with ever-changing and more demanding needs. The Seismic Flex Coupling™ is just one example of this.

Within the testing facility, a multitude of performance measurements for this product have been completed to ensure that it will meet or exceed the conditions by which it will be expected to perform.

While most water professionals and utilities will never experience the extreme seismic conditions a product such as this is designed to survive, there are other applications such as flood-prone regions where this product can be used to provide system resiliency wherever and whenever ground subsidence or shifting of any kind occurs.

We remain focused on the bigger picture and feel a great sense of responsibility and pride when developing products that will ensure the delivery of clean drinking water to millions of people.

Extreme Operating Conditions

Most waterlines operate at pressures well below 350 psi. However, there are some systems that must be designed to operate at internal pressures that may exceed 350 psi. Changes in elevations of 200, 500, or even 1000 feet may consequently increase pressures by 86.6 psi, 216.5 psi, or 433 psi, respectively.

It is also important to remember that pressure surges, often adding as much as 100 – 150 psi additional pressure, occur in most supply pipelines on any given day just from increased flow rates during peak periods of service. Typically, this is in the morning and late evenings as a community begins and ends its day.

While ductile iron pipe has a minimum of 100 psi of surge allowance incorporated into its design wall selection process, this testing facility allows us to safely explore the effects of hydrostatic pressures well above 1,000 psi, often as high as 1,800 psi in some instances. Ductile iron survives well beyond pressures where other materials fail.

There are numerous product engineers and technical professionals within the McWane family who possess the knowledge necessary to assist engineering professionals with extreme design parameters. That knowledge is supported by the proof testing completed in this state-of-the-art test facility.

State-of-the-Art Equipment

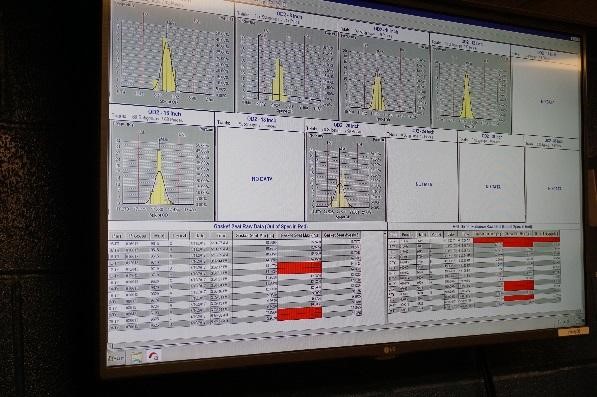

Each test completed in the Universal Test Facility is recorded and results are documented and/or recorded in perpetuity. Calibrated equipment provides the assurance that the testing is accurate.

We utilize certified equipment to ensure products are tested at maximum performance need.

Therefore, when we state that a TR FLEX® Joint can be deflected to five degrees for a Horizontal Directional Drilling (HDD) project, rest assured a test has been completed at the Universal Test Facility to validate this information is accurate.

Upon customer request, remote access during a test is available from virtually any location. Of if preferred, an on-site visit can be scheduled.

Root Cause Analysis

The Universal Test Facility was specifically designed to also provide McWane Ductile with the ability to properly identify the root cause of any potential manufacturing or installation concerns. In the field, it may be difficult to determine exactly what happened during an installation due to time constraints and field conditions.

Our team of professionals are well-equipped and very capable of determining exactly what happened in the field. Contractors and owners are now able to send returned material to our test facility where a thorough investigation is carried out. After the investigation, a Root Cause Analysis is provided in a full report, available for review by all interested parties.

Water Pressure Versus Air Pressure

Trapped air is the most common issue that interferes with a proper hydrostatic test in the field. At the Universal Test Facility, the slope of the test area has been designed to reliably exhaust all air from the test specimen during the fill process and prior to pressurization.

Failure to remove all trapped air during a hydrostatic test leads to inaccurate results and the perception of a leak. What we often call a “false-negative,” which can send a contractor into an ongoing circular waste of significant time and money chasing that turns out to be nothing. The real key to hydrostatic testing is the amount of make-up water used to maintain pressure. This is outlined in Section 5.2.1.4 Testing Allowance of the ANSI/AWWA C600 STANDARD.

McWane "Double Bump" Test

If a contractor should encounter testing issues in the field, McWane Ductile has developed and perfected a diagnostic test over the past 15 years to determine if the AWWA hydrostatic test routine is being fouled by trapped air or an actual leak in the line.

The test is called the McWane Double Bump. It consists of three (3) short (30 minutes duration) hydrostatic tests at varied (increased) pressures to assess the relative differences needed, if any, in make-up (recovery) water volumes to get back to each pressure.

While not arguing nor ignoring the AWWA acceptance criteria that ± 5 psi of the required, final test pressure should be maintained while performing an AWWA proof test, it should be noted that pressure loss alone is not an adequate judge of pass or fail, but merely an indicator.

Until you know HOW MUCH WATER YOU’RE LOSING, you are only guessing and potentially being falsely led by pressure loss alone. The McWane Double Bump is available on the McWane Ductile website, the Pocket Engineer, or via a McWane Ductile representative.

Schedule a Visit Today!

Research, compliance, or training; the Universal Test Facility is one of many ways in which McWane Ductile strives to build partnerships with water professionals and exceed expectations. From design to installation, we take great pride in providing education and assistance throughout the water industry. To arrange a visit to our Universal Test Facility, contact your local McWane Ductile representative, today!

Be sure to check out more of our Iron Strong Blogs.