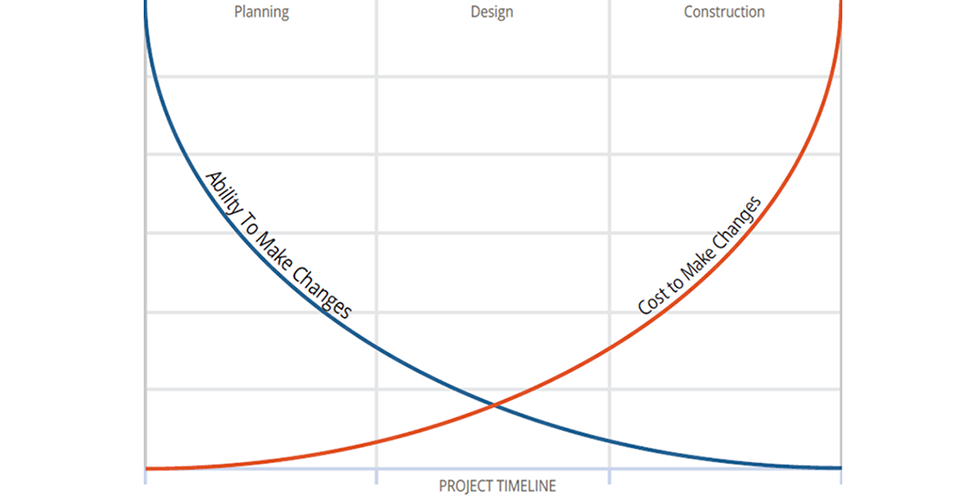

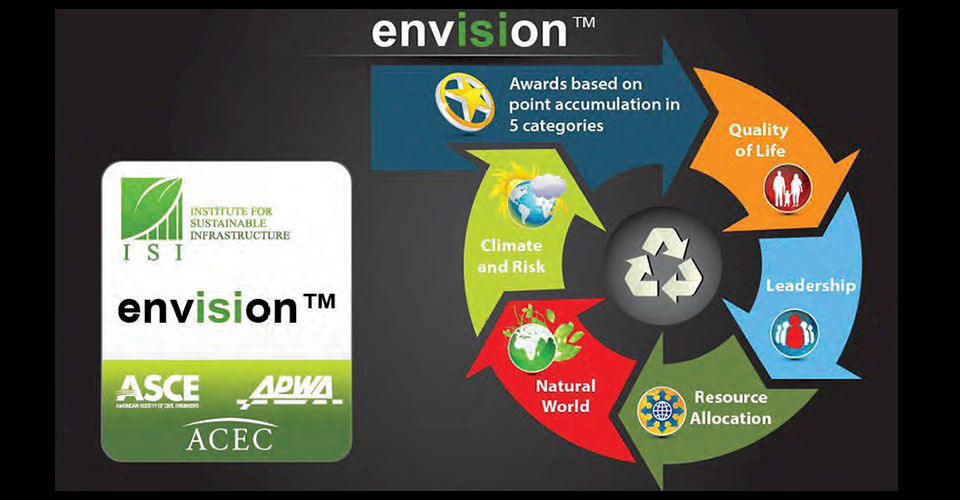

This Blog Reflects Significant Updates for EnvisionTM Manual V3. As we know, America's infrastructure is in crisis! According to the American Society of Civil Engineers, the estimated investment needed is $1 Trillion over the next 25 years for underground water infrastructure. This investment, as well as the ever-increasing cost of electricity, limited water supply, ever-decreasing natural resources, and environmental concerns, are driving the need for change. Change on how infrastructure is designed and constructed – utilizing more sustainable design and construction practices. Envision is designed to provide guidelines for these changes to North American infrastructure. In short, it is a rating system approach very similar to LEED Building Certification; however, with the focus on infrastructure. Envision not only asks, ‘Are we doing the project right?’ but also, ‘Are we doing the right project?’

How Envision Works

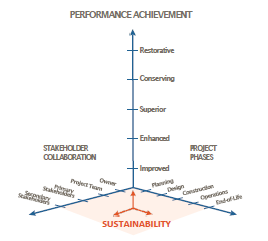

The goal of the rating system is to improve the sustainable performance of infrastructure projects from a technical perspective as well as economic, environmental, and social perspectives. It also seeks to increase sustainability performance by rewarding efforts to restore and replenish natural resources and ecosystems and evaluate the full life of the infrastructure.

And within each category are five possible levels of achievement:

- Improved

- Enhanced

- Superior

- Conserving

- Restorative

Benefits of Using Envision

The use of Envision can benefit projects in numerous ways, including:

- Long-term viability through increased resiliency and preparedness.

- Lower costs through management and stakeholder collaboration.

- Reduced negative impacts on the community and the environment.

- Potential to save owners money over time through efficiency.

- Credibility of a third-party rating system; and increased public confidence and involvement in decision making.

How Ductile Iron Pipe Excels within the Envision Rating System

To illustrate how well Ductile iron pipe (DI pipe) excels as pipe material with the Envision Rating System, specific examples from the Envision Pre-Assessment Check List V3 (where pipeline materials come into play) are listed.

Quality of Life

QL1.4 INTENT

Minimize noise and vibrations during operations to maintain and improve community livability. Reduce noise and vibration to levels below local permissible levels during construction and operation.

- When Horizontal Directional Drilling (HDD) or Pipe Bursting vs. Open Cut Trench Method is utilized, the noise impact to homes and businesses is minimized as well as the need to manage excavation spoils. This noise reduction is especially true when the Cartridge Method is utilized with 18-foot nominal length DI pipe, vs. 20-foot to 40-foot alternative pipe options. It offers the least amount of excavation, dust, and noise while achieving the highest-level score.

QL2.4 INTENT

Locate, design, and construct the project in a way that eases traffic congestion, improves mobility and access, does not promote urban sprawl, and otherwise enhances community livability.

- When replacing unreliable, outlived, and non-sustainable piping, Ductile iron improves livability within existing neighborhoods and communities by making water and sewer systems more reliable, efficient, and long-lasting. The average design life is 110 years³.

- In many parts of the country, DI pipe can outlast many other alternative materials nearly 2:1, reducing neighborhood disturbance in future construction frequency.

- Similarly, if Horizontal Directional Drilling or Pipe Bursting vs. Open Cut Trench Method is utilized, the impact on traffic flows around homes and businesses is significantly decreased. This impact is especially apparent when using the Cartridge Method (using an 18-foot nominal length DI pipe instead of 20-foot or 40-foot alternative pipe options). It provides the least amount of excavation while preserving traffic flows and access to the most significant degree.

Click here for another informative Iron Strong Blog on Horizontal Directional Drilling by my colleague, Johns Simpson

Resource Allocation

RA1.1 INTENT

Develop sustainable procurement policies and programs to source materials and equipment from manufacturers and suppliers that implement sustainable practices.

- Utilizing SMaRT Certified⁴ DI pipe made with up to 95 percent recycled content provides significantly lower net embodied energy vs. plastic pipe, such as PVC or HDPE. During the production of plastic pipe, more energy is used, and increased greenhouse gases are generated in the extraction, processing, manufacturing, and transportation of materials.

- At decommissioning, Ductile iron can be recycled again and again. Plastic pipe manufacturers do not offer sustainable products, as they are made from petrochemical processes, increasing greenhouse gases. At the end of the project life cycle, plastic pipe typically goes to a landfill, further impacting the environment.

RA1.2 INTENT

Use Recycled Materials

- Domestically manufactured DI provides up to 95 percent+ recycled content, which can easily be recycled at the end of the project life, ensuring maximum sustainability. Or the DI can be left in the ground to eventually revert to natural iron ore. Plastic pipe is made from virgin materials generated from petrochemical processes, and at the end of the project life cycle, the plastic pipe needs to be landfilled, creating additional negative environmental impact.

RA1.5 INTENT

Minimize the movement of soils and other excavated materials off-site to reduce transportation and environmental impacts.

- Due to the 60,000psi tensile strength, Ductile iron only requires a trench with an E’ of 700. So, a Type 2 Trench can be utilized using native soils. This tensile strength lowers transportation costs by eliminating the need to haul away native soils and bringing in non-native sand and gravel (a requirement if plastic or steel pipe is utilized on the pipeline project to provide mandatory trench support to those pipe materials).

RA2.1 INTENT

Conserve energy by reducing overall operation and maintenance energy consumption throughout the project life cycle.

- DIP has an average service life of 110 years and up to a 38 percent larger inside diameter vs. alternate pipe materials providing a long service life⁶, low maintenance, and substantial energy savings over alternative pipe materials.

Natural World

NW 3.1 & 3.2 INTENT

Avoid development in adverse geologic formations and safeguard aquifers to reduce natural hazards risk and preserve high-quality groundwater resources.

- If Horizontal Directional Drilling or Pipe Bursting can be utilized it will help avoid construction disturbance in adverse geologic formations and safeguard natural habitats. Areas such as streams, rivers, lakes, and marsh areas can be preserved, as the pipeline can travel under these sensitive areas. Pipe made from naturally occurring iron does not introduce human-made materials i.e., plastics. Using DI pipe significantly lowers the adverse effects on the biodiversity of these areas and preserves groundwater resources.

Climate and Resilience

CR1.1 INTENT

Reduce the impacts of material extraction, refinement/manufacture, and transport over the project life (net embodied energy and greenhouse gases).

- Ductile iron is made with up to 95 percent recycled material, is SMaRT™ Certified GOLD with the lowest Net Embodied Energy of typical municipal pipe materials. Low Net Embodied Energy as raw materials are not mined or smelted before the manufacturing process.

- Ductile iron pipe life cycle energy cost savings can be very significant through lower pumping costs (up to 38 percent lower). These savings can be computed vs alternate pipe materials using the McWane Pocket Engineer. These energy savings can then be converted into a carbon equivalent using the Energy Savings Calculator on the McWane Pocket Engineer.

CR2.5 INTENT

Increase resilience, life-cycle system performance, and the ability to withstand hazards by maximizing durability.

- Ductile iron is the only pipe material that has a Standard for Seismic Resilience ISO 16134. In areas where seismic activity is present i.e., unstable slopes, liquefaction zones, tsunamis, differential ground movement, expansive soils, or earthquakes, no other pipe material is as robust or resilient. Similarly, Ductile iron is resistant to wildfires vs. plastic pipes.

Click here for another informative Iron Strong Blog focusing on the resiliency and sustainability of Ductile iron pipelines as a result of natural disasters, by my colleague Roy Mundy.

Conclusion

The goal of Envision is to improve the sustainable performance of infrastructure projects from a technical perspective and economic, environmental, and social perspectives. ENVISION also rewards efforts to restore and replenish natural resources.

Ductile iron provides the highest level of support to Envision vs. alternate pipe materials. McWane Ductile is committed to supporting Envision & Sustainable Infrastructure design and is leading the industry by obtaining Envision SP certification for all Regional Engineers and Product Engineers.

If you have any questions regarding Envision and how it applies to your water infrastructure project, please contact your local McWane Ductile Representative. We have team members who have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal, to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.

Check Out All Our Digital Offerings

References

- American Society of Civil Engineers; (ACSE 2013) “2013 Report Card for America’s Infrastructure.”

- Institute for Sustainable Infrastructure; (ISI 2012) “ENVISION, Version 2.0 A Rating System for Sustainable Infrastructure”. Developed in joint collaboration between the Zofnass Program for Sustainable Infrastructure at the Harvard University Graduate School of Design and the Institute for Sustainable Infrastructure.

- American Water Works Association (AWWA 2012) “Buried No Longer: Confronting America’s Infrastructure Challenge”

- The Institute for Market Transformation to Sustainability

- Ductile Iron Pipe Research Association (DIPRA), https://www.dipra.org/ductile-iron-pipe/dipra-facts-and-figures/sustainable-pipe-certification, https://www.dipra.org/news-events/news/27-opinions-and-commentary/120-the-inside-story-how-a-pipe-s-inside-diameter-affects-energy-use

- Life Cycle Cost analysis, University of Michigan Study https://www.dipra.org/ductile-iron-pipe-resources/technical-publications/design?download=70:life-cycle-cost-analysis