Odds are you may not be a certified corrosion specialist or an expert in the corrosion field for that matter. Most engineers that are responsible for specifying water projects are not. There are of course engineers who dedicate their entire careers to the subject. The good news is that McWane Ductile is committed to excellence in the corrosion field and provides professionals to assist you with making sound decisions regarding corrosion control.

Methods of protecting Ductile iron pipe range from the oxide layer naturally produced during the manufacturing process to various coatings and cathodic protection systems. From the start of your project design, the first things to consider are the factors that will ultimately determine the need for corrosion protection such as location, surrounding environment, and soil. The next item to consider is the impact these factors will have on the performance of your pipeline.

After weighing all the pertinent factors and the consequence specific your project, a decision can then be made as to what type of corrosion control is needed. Our intent is not to sell you on a specific item or product, but to provide sound information for you, the water professional, so that you may develop your own conclusions.

Let’s dig deeper into two methods of corrosion enhancements, V-Bio Polyethylene Encasement and Cathodic Protection, and discuss the what, when, where, why to use them.

Corrosive Contributors

Following is a list of variables that can lead to aggressive soils. We recommend you measure these during the design phase to determine the corrosiveness of the soil:

- Resistivity

- Chlorides

- Moisture Content

- Ground Water Influence

- pH

- Sulfide Ions

- Redox Potential

- Bi-Metallic Concentrations

The above variables are described in further detail in The Design Decision Model® (DDM), a joint publication by CorrPro and Ductile Iron Pipe Research Association (DIPRA). McWane Ductile also provides an informative blog with video by John Johnson, Regional Engineer, that covers Corrosion Protection Recommendations for Ductile Iron Pipelines.

What is V-Bio and Why Install It?

V-Bio, developed by DIPRA, is a polyethylene encasement that exceeds the ANSI AWWA C105 standard for polyethylene encasement and is made up of three layers of co-extruded film infused with a corrosion inhibitor and anti-microbial additive.

This protects against most corrosive environments without involving the consumption or degradation of either corrosion inhibitors. V-Bio adds active components to a proven economical corrosion method.

V-Bio expands upon this protection by addressing the potential influence of anaerobic bacteria and inhibits the formation of corrosion cells under the wrap.

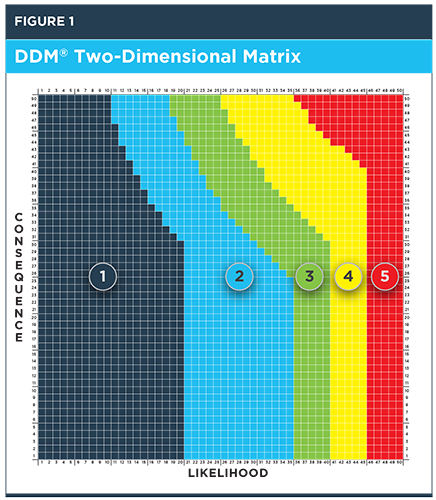

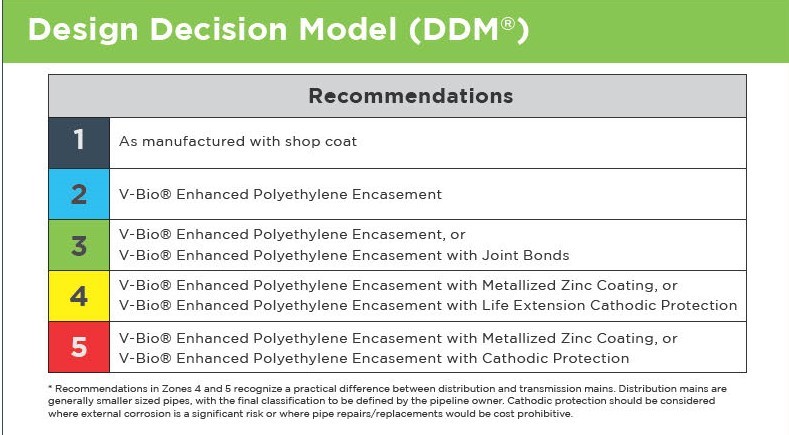

Recommendations for when to install V-Bio are provided on the Two-Dimensional Matrix found in DIPRA’s DDM .

For an informative video demonstration on how to install V-Bio in eight easy steps, see our blog by McWane Ductile Sales Rep, Aaron Loosli.

What is Cathodic Protection and Why Install It?

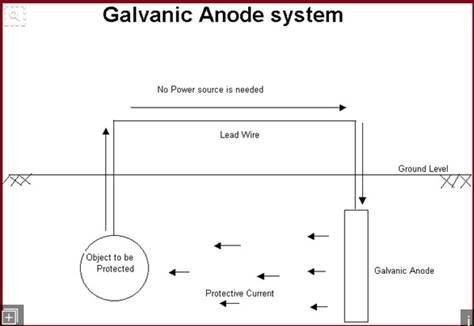

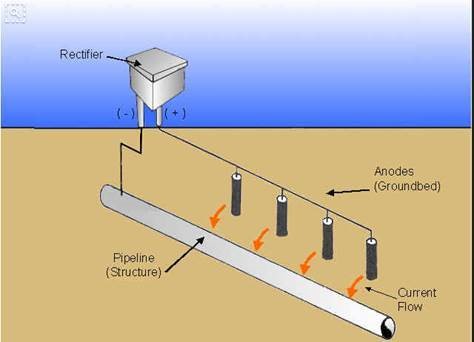

Cathodic Protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. This simple method of protection connects the metal to be protected to an easily corroded sacrificial metal to act as the anode. The sacrificial metal then corrodes instead of the protected metal. Cathodic protection protects a wide range of metallic structures in various environments.

For structures such as long pipelines where passive galvanic cathodic protection is insufficient, an external Direct Current (DC) electrical power source is used to provide a strong enough current. Cathodic protection is used extensively within the oil and gas industry to help protect non-segmented steel pipelines from corrosion.

Cathodic protection is recommend for use on Ductile iron pipe in only the most extreme corrosive environments. Since Ductile iron pipelines are made up of segmented pipe with rubberized joints every 18-20 feet, they are electronically discontinuous.

As a result, the Ductile iron joints require bonding to allow electrical current to flow along the pipeline. This allows the entire pipeline to turn into a cathode of a corrosion cell, thus protecting the pipeline from corrosion.

Because of added materials and labor to install cathodic protection, it is more expensive. It also requires more maintenance than other corrosion protection options due to the need for continuous monitoring of the cathodic protection to ensure it remains active and replaces the sacrificial anodes periodically.

To Wrap or To Sacrifice?

In summary, V-Bio is an external wrap that acts as a barrier between the pipe and the soil. V-Bio is cost-effective and protects iron pipe in almost any corrosive environment.

Cathodic Protection, involves the use of metal-to-sacrificial anodes. It is effective in extremely corrosive soils, but the cost to install and maintain cathodic protection can be expensive.

Either way, Ductile iron pipe is durable and resilient all by itself, but the best way to ensure its life span and life cycle cost are to properly protect the pipeline in harsh environments.

If you need assistance determining which protection is best suited for your pipeline system in certain soil conditions, contact your local McWane Ductile sales representative or regional engineer.

We go far beyond just manufacturing Ductile iron pipe and we would be happy to assist. We also offer on-site classroom or job-site training for you and your crews.

Check out all our digital offerings: