Polyethylene Encasement (Polywrap) was first used in 1958 and has successfully protected millions of feet of both cast and Ductile iron pipe (DI pipe). It has been the most popular method of corrosion control for DI pipe throughout the years. Today, it is the most widely used method of protecting DI pipe in corrosive environments.

Why Use V-Bio® Instead of Regular Black Polyethylene?

So, you might ask, why would I want to use V-Bio® Enhanced Polyethylene Encasement (V-Bio) for corrosion control if the regular black polyethylene has been so successful? In this Iron Strong Blog, I will point out the differences between the two polyethylene encasements.

First Polyethylene Encasement in an Operating System

First a little history. The Cast Iron Pipe Research Association (CIPRA) began experimenting with polyethylene encasement in the early 1950s. By the late 1950s, their research program led to the first use of polyethylene encasement in an operating system in Lafourche Parish, Louisiana.

This material quickly gained popularity because of its low production costs and the great protection it provided. In 2018, the pipe was inspected and revealed that after 60 years of service, polyethylene encasement offered excellent protection for this cast iron pipe in a highly corrosive environment.

Due to its success, the first national standard, ANSI/AWWA C105/21.5 was adopted in 1972.

There are also many other cases of polyethylene encasement performing well under extreme conditions. The Ductile Iron Pipe Research Association (DIPRA), the primary authority on the manufacturing, installation, and testing of Ductile iron, has tested the effectiveness of polyethylene encasements on numerous occasions.

DIPRA has conducted tests at different sites across the country and has concluded that this material can significantly extend the life expectancy of DI pipe to well beyond 100 years. These test results indicate corrosive environments may have an adverse effect which may reduce the expected service life of unprotected DI pipe.

Why Was V-Bio® Enhanced Polyethylene Encasement Developed?

Today, DIPRA is continuously working to improve Ductile iron products manufactured for the water and wastewater industries. They are continually looking for ways to help maintain and enhance DI pipe's long service life.

Their research resulted in the evolution of V-Bio® Enhanced Polyethylene Encasement, an innovative product that expands on regular polyethylene encasement’s success. The development of this revolutionary material first began in 2002. Testing began at DIPRA test sites in 2014.

V-Bio is an enhanced polyethylene encasement that provides significantly advanced corrosion protection for DI pipe. It addresses two persistent concerns that have plagued traditional polyethylene encasements.

- The potential influence of anaerobic bacteria.

- The possibility of corrosion forming under an intact wrap.

Black polyethylene wrap certainly provides enhanced protection for DI pipe. Although standard black polyethylene and V-BIO enhanced polyethylene meet the requirements of the ANSI / AWWA C105 standard of 8mil thickness, the strength of V-Bio is far superior and is less susceptible to handling damage.

Chains, steel cables, or other metal lifting devices are not recommended when installing DI pipe encased in polyethylene. Furthermore, metal lifting devices should not be used on the interior of water products in general as this may cause damage to the interior linings.

Developing a solid corrosion mitigation program to protect your investment is not as difficult as you may think. McWane Ductile provides NACE certified corrosion specialists available to assist you during the design phase of the project to help with determining proper corrosion protection for your Ductile iron pipeline project. See this helpful Iron Strong Blog by John Johnson where he delves deeper into the subject and explains the proper use of the Design Decision Model™.

What Does V-Bio® Polyethylene Consist Of?

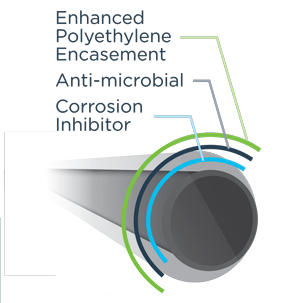

V-Bio consists of three co-extruded layers of linear low-density polyethylene film fused into a single thickness of not less than eight millimeters. This thickness is the same thickness as traditional polywrap that follows AWWA C105 8 mil minimum thickness requirement.

The inside surface of the V-Bio that meets the pipe exterior is infused with a proprietary anti-microbial to mitigate microbiologically influenced corrosion (MIC) and a volatile corrosion inhibitor to control galvanic corrosion. These function as an unbonded film to stop direct contact between the pipe itself and the surrounding soil.

The chemical additions in V-Bio provide active corrosion protection without being consumed or depleted over time. These notable additions were not present in traditional black polywrap, making it more prone to microbiologically influenced corrosion and galvanic corrosion.

The three layers of co-extruded film in V-Bio add to the material’s overall strength. The physical strength of V-Bio is 40 percent greater than the old polyethylene encasement, resulting in a more damage-resistant product. This layered structure provides greater durability and enables it to withstand more significant wear than ordinary polyethylene encasement.

V-Bio also meets all American National Standards Institute requirements and the American Water Works Association (ANSI/AWWA C105/A21.5) standards for polyethylene encasement.

How Is V-Bio® Polyethylene Encasement Installed?

As with any corrosion-protection system, proper installation is essential to the success of V-Bio Enhanced Polyethylene encasement. Care taken during installation is as important as the installation method itself.

For an informative article and video on Eight Steps for Installing V-Bio Polywrap, see our Iron Strong Blog by McWane Ductile Sales Representative Aaron Loosli.

If the V-Bio is damaged during installation, it must be repaired before the trench is backfilled. Large holes or tears should be repaired by taping another piece of V-Bio polyethylene over the hole. For another helpful demonstration on How To Repair V-Bio Polywrap in the field, check out the video below by McWane Ductile Sales Representative Aaron Loosli.

To Summarize, V-Bio® Is Best

In summary, when designing a pipeline, there is only one opportunity to design it right. Ductile iron pipe, on its own merit, is very durable. But in corrosive environments, V-Bio Enhanced Polyethylene Encasement is the next generation polyethylene that will add years to the pipe's lifespan and reduce life cycle costs.

Consider using this revolutionary polyethylene encasement for your next project. It is undoubtedly the best material that has been developed to protect DI pipe in corrosive environments.

If you have any questions regarding V-Bio for your water or wastewater infrastructure project, please feel free to contact your local McWane Ductile Sales Representative.

We have team members who have managed small and large water utility systems, served in engineering consulting firms, and bring decades of experience in solving field issues involving pipeline construction and operation. From design to submittal to installation, we strive to provide education and assistance to water professionals throughout the water and wastewater industry.